Renewable Energy

A Practical Guide to Reducing Lightning Damage and Filing Better Insurance Claims

Weather Guard Lightning Tech

A Practical Guide to Reducing Lightning Damage and Filing Better Insurance Claims

This exclusive article originally appeared in PES Wind 3-2025 in September 2025, with the title, Solving your wind farm’s lightning problem: a practical guide for operators. It was written by Allen Hall and other members of the WeatherGuard Lightning Tech team.

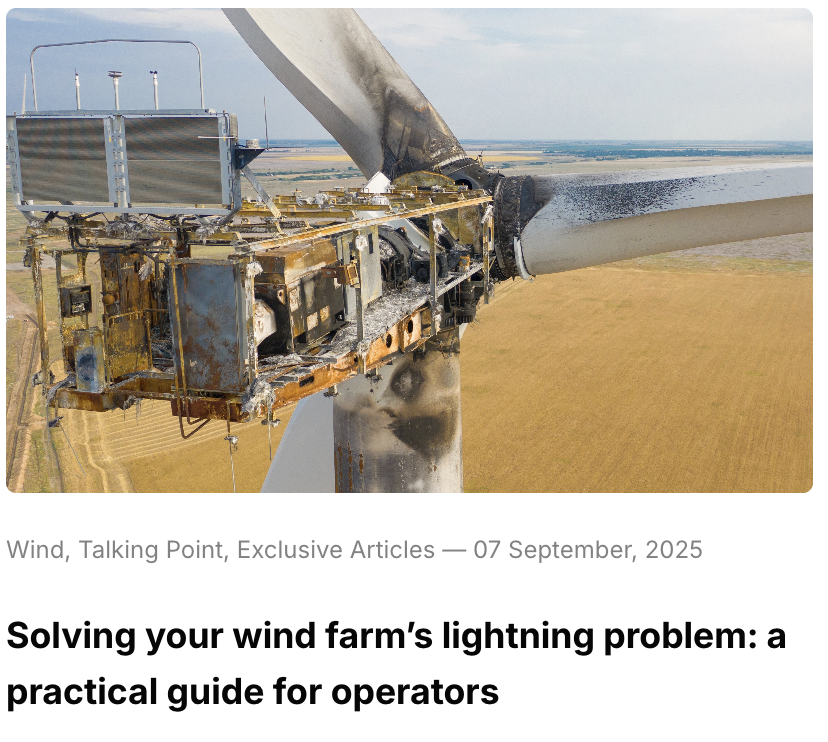

For wind farm operators, the question isn’t if lightning will cause damage. It’s how much, how often, and what can be done to reduce it. Lightning strikes are responsible for over 60% of operational blade losses and 20% of wind turbine downtime and the problem is only getting worse.

As weather patterns change, some sources predict a 12% increase in lightning activity for every 1°C of warming; follow that line of logic and countries like the US could face a 50% increase in strikes by 2100. But the future doesn’t drive wind production; operators must focus on what their next season will bring.

From hundreds of conversations with operators across the globe, we know that everyone is facing the same challenges: unclear insurance coverage, inconsistent OEM data, and costly turbine downtime. Fortunately, tackling your lightning problem doesn’t have to be overwhelming.

Here’s how to start.

Step 1: Know your equipment and its vulnerabilities

Your first step in solving lightning-related issues is understanding what you’re working with. Even within the same model, blade and lightning protection configurations may vary by manufacturer or factory. Why does this matter?

Because even small variations in blade design and grounding paths can significantly affect lightning vulnerability. Knowing your turbine configurations and LPS types is key to assessing your risk and determining the right protective strategy.

Step 2: Understand your damage history, and potential risks

For many large wind farm owners and operators, annual budgets for lightning damage repairs often exceed one million dollars. This is a significant expense that may not be fully recognized until a formal audit is conducted. Before investing in lightning mitigation solutions, it is essential to clearly define the extent of your lightning-related challenges. Start by answering these key questions.

• How much are you currently spending on repairs each year due to lightning?

• How many turbines are affected by lightning events in a typical year?

• What is the average downtime for each incident?

Collecting this internal data helps you evaluate whether a lightning mitigation solution is cost-effective. It also strengthens your case when seeking budget approvals or negotiating with insurers. Many operators do not realize how much business interruption and maintenance funding is consumed by lightning until they review the numbers in detail.

Step 3: Use strike detection and data logging

Wind farms typically have access to regional lightning detection networks, but many do not correlate this data to actual turbine damage. That’s a missed opportunity.

Surprisingly, not all wind turbines in most large farms are struck at the same rate. Turbines on the western and eastern edges will trend toward higher lightning strike rates. Higher elevations and hub heights also raise the lightning strike frequency. Each wind site is different, and strike damage can be difficult to predict. Start by installing a strike detection system on-site.

One popular choice is the EOLOGIXPING: EVENT LIGHTNING monitor, which magnetically attaches to the turbine and sends real-time alerts when a strike occurs. Combined with their lightning data service from Vaisala XWeather, you can track strike amplitudes, polarity, and frequency to easily detect damage patterns.

Step 4: Create a lightning response plan

Data is only useful if it triggers action. Create a response plan that outlines:

• What triggers an inspection, e.g., strike detection alert

• Who performs it, and how quickly

• How results are logged and communicated

This allows you to inspect only the turbines that need it, reducing costs and preventing further damage from unaddressed strikes. Studies show that unrepaired lightning damage increases the chance of repeat strikes, so rapid inspection is critical. Predictive maintenance is central to cost-effective operations. Timely actions after a strike are critical to reducing costs and preventing recurring damage.

The manner of inspection matters, too. It’s worth noting that your inspection plan must be well-documented and extremely easy to follow. Systematic and consistent data collection is the most useful for your day-to-day operations, budgeting, and insurance claims. Take photos! Document what was observed and load the information into a data management platform such as SkySpecs’ Horizon Blade Management system.

Your insurance claims groups will thank you later.

Operators that track damage immediately after a lightning event have a significant advantage; the damage doesn’t have time to grow, creating split tips or spar damage. Stopping the turbine while the damage is still repairable can cut repair costs by 75% or more.

Step 5: Revisit your insurance and OEM agreements

As lightning-related claims have surged, insurers are tightening coverage and excluding predictable lightning damage, particularly where LPS systems are ineffective. That’s a major liability for operators. Spend the time to review your policy and if anything is unclear, contact your claims representative for answers to specific questions like:

• Are lightning strikes covered?

• Are there carve-outs for known LPS defects?

• Can repeated LPS failures be considered a serial defect?

• Can you qualify for premium discounts by implementing detection or retrofits?

Transparency between OEMs and insurers is improving, but many LPS solutions remain unproven.

Operators must push for clarity and build their own protection strategy accordingly. If your turbines are under warranty or a full-service agreement, check whether lightning damage is categorized as force majeure. Many OEMs exclude it, leaving you exposed.

When the OEM does provide warranty coverage for lightning damage, having a record of when the strike occurred and the magnitude of the strike is incredibly valuable.

“Generally, the OEMs will not cover lightning events that exceed IEC 61400-24 standard and will push for details on the damaging strike. However, nearly all lightning strikes are well under the standard. Having the strike date, time, and amplitude from the strike detection system are the key to warranty pay-outs.”

Step 6: Run the numbers on LPS retrofits

Many operators are surprised to learn that OEM-installed LPS systems rarely take into account site-specific lightning risks like elevation, local storm patterns, or soil conditions. While it’s widely understood that newer turbine designs and taller towers increase lightning risk, OEM-installed LPS systems have changed little in response. Retrofitting your LPS system with a product, such as StrikeTape, offers a more reliable path for lightning to reach the ground safely. These aftermarket solutions:

• Supplement or enhance OEM systems

• Reduce blade damage

• Help meet insurer or warranty requirements Just be aware: retrofits can shift attachment points and alter current paths, so it’s critical to work with qualified engineers and product vendors who understand your exact turbine design.

Control your response to strikes

You can’t stop lightning, but you can control how your wind farm responds to it. Upgrading your protection systems and collecting meaningful strike data will give you an edge when you must deal with storm damage. And by engaging with insurance early and proactively, you’ll be in the best position to react, with professionals who are on your side. Even though it can seem like a fight to get coverage and manage necessary repairs, your goal is the same as your insurer’s. Ultimately, you both want to reduce downtime, lower repair costs, and increase your operation’s resilience in a warmer, stormier world.

Stay ahead of lightning learning curve! Contact us for help understanding your lightning damage, future risks, and how to get more uptime from your equipment.

Download the original article in PES Wind here

https://weatherguardwind.com/a-practical-guide-to-reducing-lightning-damage-and-filing-better-insurance-claims/

Renewable Energy

Open Carry in Florida

Imagine you’re a young mom, shopping for groceries with your two little kids, and you see a man with an AR-15 strapped across his back. You recognize that this is the weapon of choice for the mass murders of schoolchildren, and so perhaps you’re a bit more afraid than you would have been if it were just a holstered pistol. Are you going to be on national news for the next day or two?

The man looks like the stereotypical MAGA guy, and you remember hundreds of photos of people like him. Is he dangerous? It’s hard to tell.

What would you do?

Here’s what I would do: Leave. Noisily. “Do you think I’m shopping in a place with a guy toting a weapon designed to kill hundreds of people a minute? This is insanity. Goodbye forever. Anyone stupid enough to shop here deserves what he gets.”

Renewable Energy

Why Nuclear?

From a reader: Look at the footprint of solar panels it takes to produce the same amount as a nuclear plant, then tell me what’s better for the Earth!

From a reader: Look at the footprint of solar panels it takes to produce the same amount as a nuclear plant, then tell me what’s better for the Earth!

Needless to say, I’ve heard this a great many times over the years. The subject is a bit complex.

While it’s true that nuclear offers far better energy density that solar (and wind), this is one of many criteria we use to determine the best resource(s). We might rank our presidents on the basis of how few wars the Unites States was fighting during their tenure in office, yet there are dozens of other important criteria: economic strength, lessening the gaps between rich and poor, etc.

Another way to look at this subject is to look at competing resources in a certain region. The central part of the U.S. has incredible wind resources; a normal day in the Nebraska grid-mix offers 70% wind.

If human civilization is to avoid environmental collapse driven by climate change, nuclear is going to be absolutely necessary, but only partially due to energy density; nuclear boasts high reliability and capacity factor, as well as low operating expenses.

In all, the world needs to hope that nuclear advances quickly; we won’t do well without it.

Thanks for the comment.

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Greenhouse Gases1 year ago

Greenhouse Gases1 year ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change1 year ago

Climate Change1 year ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Greenhouse Gases2 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits

-

Renewable Energy3 months ago

US Grid Strain, Possible Allete Sale