Weather Guard Lightning Tech

FibreGlast and Bergolin: Pioneering UV Resin Systems for Blade Repair

Allen and Joel speak to Michelle Bonnett from FibreGlast and Marvin Hirdler from Bergolin about their new UV-cured resin systems for repairing wind turbine blades. These UV resins allow for faster repairs in cold weather conditions when standard epoxy resins cannot cure properly. They’re a game-changer for extending the wind turbine blade repair season and increasing technician productivity. Visit FibreGlast and Bergolin!

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Allen Hall: Welcome to the special edition of the Uptime Wind Energy podcast. I’m your host, Allen Hall, and I’m here with my co host, Joel Saxum. We’re still in San Diego at ACP OM& S, and we have run into a bunch of new technology while we’ve been at the show, and one of them is UV cured resin systems, because when it’s cold outside, You really can’t use standard epoxies and it’s cold in most of America and the world right now.

Yeah. So all repair businesses essentially shut down until it gets to about 50 degrees Fahrenheit which could be a while, particularly in the Northern latitudes. So we run into Marvin Hirdler with Bergolin and Bergolin has a new product in the UV space and also Michelle Bonnett with FibreGlast.

And I have worked with, I’ve purchased some FibreGlast material, UV care material. And it’s really awesome, actually for some projects that we were working on. This, I really want to just touch on the UV space because there hasn’t been a lot of UV resin applications in wind. We had touched From aerospace background.

We have used it there but in the wind world, we haven’t, which is crazy because we our season is so short, the repair season’s crazy. Sure. And you’re up tower and yeah, tower and access is tough. It’s really hard. But these new UV resin systems are magical. It’s crazy good. And as, as a, as someone who’s tried it, it’s amazing.

It’s amazing, and I’m surprised we haven’t done this years earlier, but it’s, it’s finally coming to market. I want to talk about this, the one I use first, which is the FibreGlast repair patch. So Michelle, maybe you can introduce yourself a little bit, but you guys, FibreGlast is based in Ohio, right?

So you’re a U. S. based company, and FibreGlast does all kinds of things, fiber related, resin related, you’re like a resource.

Michelle Bonnett: Yes. Correct. Where we’ve been in business for about 65 years where our website is fibreglast.com. We sell to a guy in his garage doing a small repair to a lot of large companies in the aerospace automotive.

And of course wind. We Work predominantly with small quantities. We ship them very fast. If you order before two 30 Eastern time, they ship same day. So it is imperative in the wind industry to get those products out quick. We teamed up with a company called SunRes that has been an industry leader in UV for about correct me if I’m wrong, but around 30 years.

And recently got GE approved UV prepreg. So it’s a 300 by 700 millimeter patch. It comes in UD1000, Biax 806, and the Combi 900. It is a vinyl ester resin. That is cured UV. You can typically lay up about 10 layers. Very easy patches that you can build very quickly, get it up to the blade and apply.

Joel Saxum: One of the things I want to touch on that you said there, and this is super important for the space, right? Anybody that’s an ISP, blade repair, that’s listing, or an asset owner, is that it is GE approved. Yes. Because I know we were at Blades USA, and we were all talking through some of these new UV cured systems, and that was some of the ISP saying this is great.

We can take A project that normally would take us six hours to let some cure and do some layering. Now it takes us ten minutes. That’s a game changer for everybody, right? And in different weather conditions, which is even better. But, is it approved? Can we use it on specific blades? Will the OEM still, honor warranties or things like this?

That was one of some of the big questions. And to say that product is GE says, yes, good to go. That’s huge. That’s not just social proof. That’s technical proof. We can use these products in the field and trust them.

Michelle Bonnett: Correct. And we do carry a non hazardous. It’s an accolade, a modified accolade epoxy.

In these 12 by 12 patches, chopstrap mat and the combi 900 as well. Those are currently with G. E. And testing to get that non hazardous approved. Yeah, FibreGlast is really good. We’re all hazard trained. ship dangerous goods, we overnight stuff when needed. And so these hazardous patches can be shipped for an expense.

The non hazardous is a game changer because it takes that money away and lets us ship overnight without any additional costs. It is with currently with GE, they are testing to make sure, but you really won’t see any type of difference in strength properties all of that. So it should be.

As quick as GE can get approved fairly quickly. So that’s one of the things that we’re working on, but we do carry the 12 by 12 patches as well as those approved hazardous 300 millimeter by 700 millimeter patch.

Allen Hall: And that, that, that patch you buy, since I purchased this thing, it comes in a sort of four line pouch that it’s all ready to go.

You open the pouch, you slide the patch out, you apply it to the Turbine blade, roll it in, kick it off if you need to. It has a plastic, a clear plastic coating on it, so it hardens on the surface. That’s one of the things that everybody, I think, needs to know, right? Is that you, there is a plastic coating over top of the material, so that it doesn’t oxidize and remain sticky.

It’ll cure out all the way perfectly, which is really simple to use. I, even, electrical engineer me, was able to do it. But it is one of those things it’s a little bit different than maybe a standard epoxy. But It’s really simple. If I had to do a quick repair out somewhere in January or February on a wind turbine, that’s what I’m using, because I can do it.

Michelle Bonnett: And that the hazardous material comes with and everything’s color coded. So you have a black plastic lining that you would initially take off to put on the blade followed by a P. E. T. Clear that remains on there because it is a vinyl Lester. So it does need that airless skin, airless finish.

And then it has an orange an orange material that is UV blocking. So what that allows you to do is apply however long it takes you to apply. Then you remove that orange film and bam, that’s when the sun hits. Now, we really recommend the L. E. D. U. V. Lamps. Even out in the field where the sun is present when you’ve got sun out and that what that does is it just, it cures a little quicker.

So we’re talking instead of five to 10 minutes, you’re talking three to five minutes. But it also gives you that consistency. You can make sure that it’s cure. Sometimes if the sun doesn’t quite hit or you get a cloud or something like that might happen, you might not get consistent UV. And so that lamp is important.

Joel Saxum: So let me ask you about that lamp. Now I’m just like from an operational perspective, right? If people are on ropes or in a, in a basket or something, that’s a different story. But what are this, what size is this? What are those? Are they? No, the lamp itself. Oh, the lamp itself, I don’t know why they got to work with that tower.

It’s about 10 by, I think 10 by 12, it’s, it is fairly small.

Michelle Bonnett: You hold it about 13 feet from from the The cure itself. Thirteen feet? Oh, sorry, thirteen inches. Oh, I was like, how are you going to do that? Thirteen feet! You’ve got some really long arms. What I love about it is it has very different mounting capabilities.

So you can either strap it to hold it does have some handles that you can use. Okay. There’s just different ways and different methods that you can use to strap it onto something or secure it to someplace.

Joel Saxum: So if you’re on ropes, it’s not too bad to just take it with you.

Michelle Bonnett: Correct. Yeah, it would hang off of a, a belt.

It’s really lightweight.

Allen Hall: Okay, perfect. So the magic to this is that the UV light is triggering a chemical reaction. It’s breaking some bonds or triggering some bonds so that it starts to, the material warms up itself, it self heats and self cures, so it’s like having a heat gun without having a heat gun.

Using a lamp to trigger the heat in material, and boom, it cures out. It’s magical. Yeah, let’s find a watch and play with.

Joel Saxum: Yeah, and that’s the game changing is right something like we said earlier That would be six to eight hours between layers between top coat and all these different things now Ten minutes because it’s cured hard.

Michelle Bonnett: The best part about it is humidity levels Temperature none of that is important It just takes that out completely.

We had done some testing when we first started carrying this material and we were in 30 degrees, just sat it out on a picnic table, five minutes, it was cured, completely cured. 30 Fahrenheit, right? Yeah, 30 Fahrenheit.

Allen Hall: So in the, let’s, I want to touch on this just for a brief moment. When we say hazardous and non hazardous, what we’re saying is polyester hazardous.

It’s the odor of the thing. It has a certain odor to it. If you’ve been around polyester and the standard. Non hazardous, which is epoxy, has really no smell to it. No smell to it at all.

Michelle Bonnett: Yeah, a lot of the demos that we’ve been doing at some of the different shows are very much inside a hotel and you just can’t have, yeah, you just can’t have that vinylester, polyester, the styrene smell that everybody’s aware of.

Joel Saxum: Right from the booth every once in a while, we’re there and we go, oh, wow, what is that? They cured it and they’re hitting it with a hammer. Yeah, whacking it with a hammer.

Allen Hall: Yeah, it’s amazing material. And I want to start talking about the burgundy material because this is something new too. Yeah. And Bergolin is based out of what country?

Marvin Hirdler: Germany. Based in Germany. We’re working in WIND over 20 years already. Yes. We are from the coding side. We started with J codes, fillers, top codes, LEP systems. Yep. In the manufacturing side, for sure. And then, I would say three to five years ago, we started also going into blade repair business.

Yeah. Because, yeah, the OEMs are asking for it. We need a different solution. Same application or different application methods has to be faster, easier to apply, robust access, platform, whatever you have. So this was the reason we started going into the blade repair. And last year or one and a half years ago, we started thinking about UV materials.

So we started manufacturing not only, but also developing a UV filler first. So this was the first material we launched into the market not only for blade repair, but also for other composite repairs.

Allen Hall: Okay, so avoid leading edge damage or something to fill in the little bumps and the bruises.

Okay.

Marvin Hirdler: And yeah, especially the good thing with the UV material is always you have a single part material. You don’t have to mix anymore. You don’t have to. True. Yeah. The chrome wife goes away and all the mixing goes away.

Allen Hall: The mixing nozzles and all the craziness involved with that. Yeah.

You’ve seen errors. You just gotta keep it. There’s so many errors with the mixing nozzle. Just keep it dark. Make sure the sun doesn’t get in there. But it’s not that sensitive to light. The Birkeland material is very narrow frequency, light frequency, to make it trigger.

Marvin Hirdler: Exactly. So we have found a way to integrate a UV blocker inside the material.

So if you apply this material, the filler and the resin too, it’s the same chemistry in the sun directly, it will not cure without the curing lamp. So you can do it in the sun. Depending on the UV index, you will have an amount of time. So with a filler, for example, when we have a very high UV index, we tested it here in Texas last year.

UV index 9, 100 degrees Fahrenheit. And you still have three minutes to apply the filler, probably in the sun. Wow. Okay, and then you put the uv lamp on top and then it starts curing.

Allen Hall: Okay, so in the other piece to the burglar material, which is called i’m going to get this right Burgle lead.

Yeah for led Bergl is it BergoLED? Yeah, it’s BergoLED. Yeah, you can BergoLED Okay. All right. So it’s a speed resin I think is how we would say in america speed resin. That’s what’s going to stick is it’s it has a color to it So we apply the resin so you have dry fabric from FibreGlast and you’re applying the resin to It’s red or a pinkish color.

Yeah. Yeah, so the UV light when you kick it off turns it clear So exactly what are you doing? I think this is the problem that everybody’s worried about when I do 5, 8, 10 layers of repair. How do I know I got the UV down to that last layer? With the tinting part of it, that eliminates that as a question.

Yeah. It just changes colors.

Marvin Hirdler: Especially when we’re doing it in blade repair, we were not aware how easy it would be to test if all the layers cured through. It’s easy testing with epoxy, you go ahead, the curve of the temperature and everything. You don’t have that with the UV material.

It’s not getting hot or whatever. So we found a way. This is yeah, an initiator from a different industry and we use it normally for floor coatings. Because they doing the same thing with the UV stuff and it’s first blue or red and then they see if it’s cured or not It’s colorless afterwards.

Okay, so we use the same thing this is cool.

Joel Saxum: Okay, it’s So they make this product for like at Home Depot. You can buy it not the same product no, same concept. It’s a like putty You’d fill nail holes within the wall, right? And when you put it on it’s pink and when it dries better It drives white.

Oh. It’s just, it’s, but it’s genius. I always buy it when I need it because I want to know when the job is done. Exactly. And then you see all these little pink dots all over the place and in 10 minutes they all turn white and you’re like, all right, we’re good here. We can paint over it. Oh, okay. It’s slick.

Slick as hell.

Marvin Hirdler: Yeah, just make it easier, especially for the text to see directly in visual if it’s cured or not. So this is something we figure out. It’s the same with the putty or the putty too. So we have also the same idea. First red, then colorless after curing. So just make sure you can do a repair, the whole repair with just visual looking, okay, it’s cured or not.

Joel Saxum: I think that there’s something important here to touch on. So cost of poor quality, COPQ as it’s called in business, is a huge thing in the wind industry because The engineers are not on the blades and they’re the ones that have to look at the repairs to make sure they’re well done. Your blade text, that’s the front line.

That’s the people you have to trust. But what happens of course in the world as people who listen, know this, you’re in the field, you’re taking pictures, putting together repair reports, all this stuff, and then that gets sent to the back office or sent to the client. They have to approve it. And, or you may have to come back up.

Sometimes it’s live where they’re taking pictures right now and someone’s looking at them remotely to make sure the repair is done properly. And what you guys are doing is engineering a, now a product. Of that process, you’re dummy proofing it. Yeah. This is the idea, right? It was red, it’s clear now.

Yeah, you are good to go. There’s no approval needed. Is.

Allen Hall: Just think about it, all the porcelain. Yes, I know. The temperature outside, the humidity outside, and all of that. And then, obviously, bring water or something to cure out before they start playing the top coat to it.

Joel Saxum: Yeah, I mean, it’s the solution that you’re putting forth for solutions.

Is part of the solution for scaling the wind technician fleet of people?

Allen Hall: Yeah, we need to extend our window. The technicians are essentially sitting on the sidelines for six months out of a year. Yeah, that’s crazy. We need to put the guys back to work and to start fixing blades because, and especially at this conference where you walk through the halls here and start talking operators, everybody, cause it’s February, everybody’s got huge blade issues.

They got a lot of blades. Can they even get them all done this year? The season’s short. They’re trying to schedule people’s, not enough technicians. If you just double the amount of time you have to go and do some of these things makes life a lot easier.

Joel Saxum: And you’re cutting down on the time on Blade and on project.

Yeah, too. Yeah. That’s the big, speeding it up quite a bit. Yeah. Yeah. Because now a team of a rope access team with two people on it, and instead of, fixing one turbine per week, they can now maybe fix three. Sure. That’s huge. Yep. Yep. It’s the speed.

Marvin Hirdler: We talked about that. Especially when we talk about like the.

Countries North Canada or also the North US states. So they had the biggest issue especially in winter doing no repair at all And yeah, just certain so we’re talking about turbines who is just standing still not producing any energy so this is the reason we’re trying to get in contact most of the time Starting with operators owners because they have to pay for it Sure, and they have to pay or not getting paid for downtime So they’re trying to make it fast Even if it’s just in the beginning a temporary repair with the uv materials because they say okay We want to test that first Seeing the same repair in six, eight months later in the summer, everything is good.

But so they can start use the turbine again in operation. So they don’t have the downtime at all. And now they just have to wait until the temperature is high enough. Humidity is low enough, whatever they have limitations on.

Joel Saxum: Yeah. That’s something that you see quite often in the industry is Hey, we’ve got a damage.

We need to patch this thing just to get it through the winter. Because if you get ice, snow, water, anything in there, and then your core gets wet, then you end up running into real big problems. So now you have a solution where you can go into a temporary repair. It’s technically permanent, but yeah, but you could go up there and you can slap one of those panels on UV cure, move on to the next one before wet weather changes.

Allen Hall: It’s genius. Yeah, it really is. And I know when I first saw FibreGlast website, like, why haven’t I seen this before? And we just released it. So you had a good, you had a good reason for it because you just brought it out. But I was probably one of the early people to see it and try to try it. So it’s amazing.

And I if I’m an operator trying, want to try this material, cause they don’t want to try it, they want to check in or independent service provider, they want to play with the material before they take it out in the field. What do they need to do? Who are they calling? Are they calling FibreGlast here?

Are they calling Michelle and saying, hey, give me a sample, send me a sample? Exactly. And what should they be asking for? They should be asking for polyester, the polyester material for GE turbines, the epoxy for Vestas. What’s the scenario here?

Michelle Bonnett: Right now, probably the hazardous is the most popular.

Okay. But. Any of them, like I said the strength properties, all of the properties are almost identical to the data sheet there. You can download on the website. We have our, the product data sheet and the SDS available. For you to take a look decide what you want. Our business development manager, his name is Rod Miaty.

He’s over at our, he’s manning the booth while we’re over here. Yeah. He’s the guy to get in touch with. Yes. Rod Miaty. Yeah. Rod Miaty.

He is the, probably the best person or call up customer service. They’ll be happy to process one for you. Okay. The best part about these things is we I, if you buy direct from Sunrise, you’re buying boxes of this stuff.

We do like to downsize. So our 12 by 12 patches, you could buy a single patch, you could buy a pack of 12, you could buy a case of 10. And same with the the other patches are in packs of 10 or in a case. So we can get some samples out to you. Let you give it a try. The 300 by 700 millimeter patches, they’re very easy to cut.

As well and very easy to use as far as just peeling everything off, all of the packages have your step by step instructions on what you do, which film to release, what, everything that you do, very clear, very concise to make sure that there’s not anything, our customer service is trained, you can call the 800 number if you’re having problems they can talk you through something, but yeah, definitely give us a call place an order through the website or contact rod.

Allen Hall: Yes. And it’s FibreGlast, F I B R E G L A S T. So you just Google that and you’re going to get to Michelle’s website. All right. For Bergolin, how are we getting a hold of Bergolin, because you guys are over in Germany and this podcast goes worldwide, so you’re going to have people calling you from all over the world.

How do they get a hold of you?

Marvin Hirdler: Yeah. I run the whole US business here, so I do the technical training, the commercial side too. Also we operating or helping also the training companies like Redwood Academy, TSL Windtrade company too, to make sure that they get the hold of the materials. Sure.

So I trained the trainer. I’ve been there, I doing, two or three trainings a week right now because everyone is interested in the new materials for sure, right? So I make sure that they get their first training with me and then they can train their technicians Okay, we even have a process description where everything every step is perfectly written down with pictures.

So how close you have to go with the lamp? How many layers you have to you need to apply in one step that section? So if you have to help you apply or do a vacuum so I just want to make sure that there are no questions at all afterwards. If there are any questions, they always can call us.

Allen Hall: And your YouTube video you sent me today.

Yeah. Which is very explanatory, so yeah, you can get a lot of information. So easy, a lightning engineer can do it. Yeah. I am not a composites expert for sure. Actually, this was the idea we had.

Get it that simple everybody, huh? Bergolin is B E R G O L I N. If you just Google that and put UV behind it, you’re going to come across the UV material.

It’s fantastic stuff. So if you’re a technician, you’re an operator, you’re an ISP looking to speed up operations or extend your season, you need to get a hold of Michelle. I need to get a hold of Marvin and talk UV cured resins. So it’s the future. So thanks to both of you being here. Thank you.

FibreGlast and Bergolin: Pioneering UV Resin Systems for Blade Repair

Renewable Energy

A Lesson from the Early 20th Century

My maternal grandfather was born in southeastern Pennsylvania in 1903 and told me when I was a boy that in the 1920s, times were so good that saloon owners would offer a free lunch, consisting of bread and butter, cheese, cold cuts, pickles and the like. “Sure, they were hoping you’d buy a glass of beer for a nickel, but they really didn’t mind if you didn’t and simply scarfed down a free sandwich.”

My maternal grandfather was born in southeastern Pennsylvania in 1903 and told me when I was a boy that in the 1920s, times were so good that saloon owners would offer a free lunch, consisting of bread and butter, cheese, cold cuts, pickles and the like. “Sure, they were hoping you’d buy a glass of beer for a nickel, but they really didn’t mind if you didn’t and simply scarfed down a free sandwich.”

He went on to tell me that nowadays, there’s a popular slogan: There’s no such thing as a free lunch, “but believe me, there was at the time.”

From today’s perspective of greed and selfishness, this whole story sounds like a fairy tale. Corporations and the congresspeople they own want one thing: to suck the life out of us.

Renewable Energy

Wind Industry Operations: In Wind’s Next Chapter, Operations take center stage

Wind Industry Operations: In Wind’s Next Chapter, Operations take center stage

This exclusive article originally appeared in PES Wind 4 – 2025 with the title, Operations take center stage in wind’s next chapter. It was written by Allen Hall and other members of the WeatherGuard Lightning Tech team.

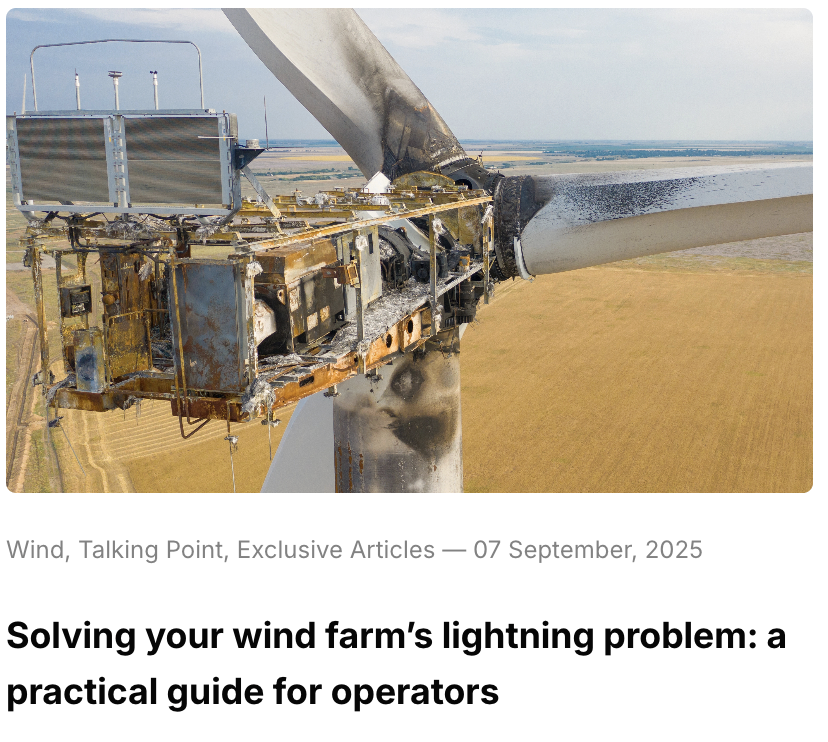

As aging fleets, shrinking margins, and new policies reshape the wind sector, wind energy operations are in the spotlight. The industry’s next chapter will be defined not by capacity growth, but by operational excellence, where integrated, predictive maintenance turns data into decisions and reliability into profit.

Wind farm operations are undergoing a fundamental transformation. After hosting hundreds of conversations on the Uptime Wind Energy Podcast, I’ve witnessed a clear pattern: the most successful operators are abandoning reactive maintenance in favor of integrated, predictive strategies. This shift isn’t just about adopting new technologies; it’s about fundamentally rethinking how we manage aging assets in an era of tightening margins and expanding responsibilities.

The evidence was overwhelming at this year’s SkySpecs Customer Forum, where representatives from over 75% of US installed wind capacity gathered to share experiences and strategies. The consensus was clear: those who integrate monitoring, inspection, and repair into a cohesive operational strategy are achieving dramatic improvements in reliability and profitability.

Takeaway: These options have been available to wind energy operations for years; now, adoption is critical.

Why traditional approaches to wind farm operations are failing

Today’s wind operators face an unprecedented convergence of challenges. Fleets installed during the 2010-2015 boom are aging in unexpected ways, revealing design vulnerabilities no one anticipated. Meanwhile, the support infrastructure is crumbling; spare parts have become scarce, OEM support is limited, and insurance companies are tightening coverage just when operators need them most.

The situation is particularly acute following recent policy changes. The One Big Beautiful Bill in the United States has fundamentally altered the economic landscape. PTC farming is no longer viable; turbines must run longer and more reliably than ever before. Engineering teams, already stretched thin, are being asked to manage not just wind assets but solar and battery storage as well. The old playbook simply doesn’t work anymore.

Consider the scope of just one challenge: polyester blade failures. During our podcast conversation with Edo Kuipers of We4Ce, we learned that an estimated 30,000 to 40,000 blades worldwide are experiencing root bushing issues. ‘After a while, blades are simply flying off,’ Kuipers explained. The financial impact of a single blade failure can exceed €300,000 when you factor in replacement costs, lost production, and crane mobilization. Yet innovative repair solutions, like the one developed by We4Ce and CNC Onsite, can address the same problem for €40,000 if caught early. This pattern repeats across every major component. Gearbox failures that once required complete replacement can now be predicted months in advance. Lightning damage that previously caused catastrophic failures can be prevented with inexpensive upgrades and real-time monitoring. All these solutions are based on the principle that predicted maintenance is better than an expensive surprise.

Seeing problems before they happeny, and potential risks

The transformation begins with visibility. Modern monitoring systems reveal problems that traditional methods miss entirely. Eric van Genuchten of Sensing360 shared an eye-opening statistic on our podcast: ‘In planetary gearbox failures, they get 90%, so there’s still 10% of failures they cannot detect.’ That missing 10% represents the catastrophic failures that destroy budgets and production targets. Advanced monitoring technologies are filling these gaps. Sensing360’s fiber optic sensors, for example, detect minute deformations in steel components, revealing load imbalances and fatigue progression invisible to traditional monitoring. ‘We integrate our sensors in steel and make rotating equipment smarter,’ van Genuchten explained.

Other companies are deploying acoustic systems to identify blade delamination, oil analysis for gearbox health, and electrical signature analysis for generator issues. Each technology adds a piece to the puzzle, but the real value comes from integration. The impact of load monitoring alone can be transformative.

As van Genuchten explained, ‘Twenty percent more loading on a gearbox or on a bearing is half of your life. The other way around, twenty percent less loading is double your life.’ With proper monitoring, operators can optimize load distribution across their fleet, extending component life while maximizing production.

But monitoring without action is just expensive data collection. The most successful operators are those who’ve learned to translate sensor data into operational decisions. This requires not just technology but organizational change, breaking down silos between monitoring, maintenance, and management teams.

In Wind Energy Operations, Early intervention makes the million-dollar difference

The economics of early intervention are compelling across every component type. The blade root bushing example from We4Ce illustrates this perfectly. With their solution, early detection means replacing just 24-30 bushings in about 24 hours of drilling work. Wait, and you’re looking at 60+ bushings and 60 hours of work. Early detection doesn’t just prevent catastrophic failure; it makes repairs faster, cheaper, and more reliable.

This principle extends throughout the turbine. Early-stage bearing damage can be addressed through targeted lubrication or minor adjustments. Incipient electrical issues can be resolved with cleaning or connection tightening. Small blade surface cracks can be repaired in a few hours before they propagate into structural damage requiring weeks of work.

Leading operators are implementing tiered response protocols based on monitoring data. Critical issues trigger immediate intervention. Developing problems are scheduled for the next maintenance window. Minor issues are monitored and addressed during routine service. This systematic approach reduces both emergency repairs and unnecessary maintenance, optimizing resource allocation across the fleet.

Turning information into action

While monitoring generates data, platforms like SkySpecs’ Horizon transform that data into operational intelligence. Josh Goryl, SkySpecs’ Chief Revenue Officer, explained their evolution at the recent Customer Forum: ‘I think where we can help our customers is getting all that data into one place.

The game-changer is integration across data types. The company is working to combine performance data with CMS data to provide valuable insights into turbine health. This approach has been informed by operators across the world, who’ve discovered that integrated platforms deliver insights that siloed data can’t.

The platform approach also addresses the reality of shrinking engineering teams managing expanding portfolios. As Goryl noted, many wind engineers are now responsible for solar and battery storage assets as well. One platform managing multiple technologies through a unified interface becomes essential for operational efficiency.

The Integration Imperative for Wind Farm Operations

The most successful operators aren’t just adopting individual technologies; they’re integrating monitoring, inspection, and repair into a seamless operational system. This integration operates at multiple levels.

At the technical level, data from various monitoring systems feeds into unified platforms that provide comprehensive asset visibility. These platforms don’t just display data; they analyze patterns, predict failures, and generate work orders.

At the organizational level, integration means breaking down barriers between departments. This cross-functional collaboration transforms O&M from a cost center into a value driver. Building your improvement roadmap For operators ready to enhance their O&M approach, the path forward involves several key steps:

Assessing the Current State of your Wind Energy Operations

Document your maintenance costs, failure rates, and downtime patterns. Identify which problems consume the most resources and which assets are most critical to your wind farm operations.

Start with targeted pilots Rather than attempting wholesale transformation, begin with focused initiatives targeting your biggest pain points. Whether it’s blade monitoring, gearbox sensors, or repair innovations, starting with your largest issue will help you see the biggest benefit.

• Invest in integration, not just technology: the most sophisticated monitoring system is worthless if its data isn’t acted upon. Ensure your organization has the processes and culture to transform data into decisions – this is the first step to profitability in your wind farm operations.

Build partnerships, not just contracts: look for technology providers and service companies willing to share knowledge, not just deliver services. The goal is building capability, not dependency.

• Measure and iterate: track the impact of each initiative on your key performance indicators. Use lessons learned to refine your approach and guide future investments.

The competitive advantage

The wind industry has reached an inflection point. With increasingly large and complex turbines, monitoring needs to adapt with it. The era of flying blind is over.

In an industry where margins continue to compress and competition intensifies, operational excellence has become a key differentiator. Those who master the integration of monitoring, inspection, and repair will thrive. Those who cling to reactive maintenance face escalating costs and declining competitiveness.

The technology exists. The business case is proven. The early adopters are already reaping the benefits. The question isn’t whether to transform your O&M approach, but how quickly you can adapt to this new reality. In the race to operational excellence, the winners will be those who act decisively to embrace the efficiency revolution reshaping wind operations.

Unless otherwise noted, images here are from We4C Rotorblade Specialist.

Contact us for help understanding your lightning damage, future risks, and how to get more uptime from your equipment.

Download the full article from PES Wind here

Find a practical guide to solving lightning problems and filing better insurance claims here

Wind Industry Operations: In Wind’s Next Chapter, Operations take center stage

Renewable Energy

BladeBUG Tackles Serial Blade Defects with Robotics

Weather Guard Lightning Tech

BladeBUG Tackles Serial Blade Defects with Robotics

Chris Cieslak, CEO of BladeBug, joins the show to discuss how their walking robot is making ultrasonic blade inspections faster and more accessible. They cover new horizontal scanning capabilities for lay down yards, blade root inspections for bushing defects, and plans to expand into North America in 2026.

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

Welcome to Uptime Spotlight, shining Light on Wind. Energy’s brightest innovators. This is the Progress Powering Tomorrow.

Allen Hall: Chris, welcome back to the show.

Chris Cieslak: It’s great to be back. Thank you very much for having me on again.

Allen Hall: It’s great to see you in person, and a lot has been happening at Blade Bugs since the last time I saw Blade Bug in person. Yeah, the robot. It looks a lot different and it has really new capabilities.

Chris Cieslak: So we’ve continued to develop our ultrasonic, non-destructive testing capabilities of the blade bug robot.

Um, but what we’ve now added to its capabilities is to do horizontal blade scans as well. So we’re able to do blades that are in lay down yards or blades that have come down for inspections as well as up tower. So we can do up tower, down tower inspections. We’re trying to capture. I guess the opportunity to inspect blades after transportation when they get delivered to site, to look [00:01:00] for any transport damage or anything that might have been missed in the factory inspections.

And then we can do subsequent installation inspections as well to make sure there’s no mishandling damage on those blades. So yeah, we’ve been just refining what we can do with the NDT side of things and improving its capabilities

Joel Saxum: was that need driven from like market response and people say, Hey, we need, we need.

We like the blade blood product. We like what you’re doing, but we need it here. Or do you guys just say like, Hey, this is the next, this is the next thing we can do. Why not?

Chris Cieslak: It was very much market response. We had a lot of inquiries this year from, um, OEMs, blade manufacturers across the board with issues within their blades that need to be inspected on the ground, up the tap, any which way they can.

There there was no, um, rhyme or reason, which was better, but the fact that he wanted to improve the ability of it horizontally has led the. Sort of modifications that you’ve seen and now we’re doing like down tower, right? Blade scans. Yeah. A really fast breed. So

Joel Saxum: I think the, the important thing there is too is that because of the way the robot is built [00:02:00] now, when you see NDT in a factory, it’s this robot rolls along this perfectly flat concrete floor and it does this and it does that.

But the way the robot is built, if a blade is sitting in a chair trailing edge up, or if it’s flap wise, any which way the robot can adapt to, right? And the idea is. We, we looked at it today and kind of the new cage and the new things you have around it with all the different encoders and for the heads and everything is you can collect data however is needed.

If it’s rasterized, if there’s a vector, if there’s a line, if we go down a bond line, if we need to scan a two foot wide path down the middle of the top of the spa cap, we can do all those different things and all kinds of orientations. That’s a fantastic capability.

Chris Cieslak: Yeah, absolutely. And it, that’s again for the market needs.

So we are able to scan maybe a meter wide in one sort of cord wise. Pass of that probe whilst walking in the span-wise direction. So we’re able to do that raster scan at various spacing. So if you’ve got a defect that you wanna find that maximum 20 mil, we’ll just have a 20 mil step [00:03:00] size between each scan.

If you’ve got a bigger tolerance, we can have 50 mil, a hundred mil it, it’s so tuneable and it removes any of the variability that you get from a human to human operator doing that scanning. And this is all about. Repeatable, consistent high quality data that you can then use to make real informed decisions about the state of those blades and act upon it.

So this is not about, um, an alternative to humans. It’s just a better, it’s just an evolution of how humans do it. We can just do it really quick and it’s probably, we, we say it’s like six times faster than a human, but actually we’re 10 times faster. We don’t need to do any of the mapping out of the blade, but it’s all encoded all that data.

We know where the robot is as we walk. That’s all captured. And then you end up with really. Consistent data. It doesn’t matter who’s operating a robot, the robot will have those settings preset and you just walk down the blade, get that data, and then our subject matter experts, they’re offline, you know, they are in their offices, warm, cozy offices, reviewing data from multiple sources of robots.

And it’s about, you know, improving that [00:04:00] efficiency of getting that report out to the customer and letting ’em know what’s wrong with their blades, actually,

Allen Hall: because that’s always been the drawback of, with NDT. Is that I think the engineers have always wanted to go do it. There’s been crush core transportation damage, which is sometimes hard to see.

You can maybe see a little bit of a wobble on the blade service, but you’re not sure what’s underneath. Bond line’s always an issue for engineering, but the cost to take a person, fly them out to look at a spot on a blade is really expensive, especially someone who is qualified. Yeah, so the, the difference now with play bug is you can have the technology to do the scan.

Much faster and do a lot of blades, which is what the de market demand is right now to do a lot of blades simultaneously and get the same level of data by the review, by the same expert just sitting somewhere else.

Chris Cieslak: Absolutely.

Joel Saxum: I think that the quality of data is a, it’s something to touch on here because when you send someone out to the field, it’s like if, if, if I go, if I go to the wall here and you go to the wall here and we both take a paintbrush, we paint a little bit [00:05:00] different, you’re probably gonna be better.

You’re gonna be able to reach higher spots than I can.

Allen Hall: This is true.

Joel Saxum: That’s true. It’s the same thing with like an NDT process. Now you’re taking the variability of the technician out of it as well. So the data quality collection at the source, that’s what played bug ducts.

Allen Hall: Yeah,

Joel Saxum: that’s the robotic processes.

That is making sure that if I scan this, whatever it may be, LM 48.7 and I do another one and another one and another one, I’m gonna get a consistent set of quality data and then it’s goes to analysis. We can make real decisions off.

Allen Hall: Well, I, I think in today’s world now, especially with transportation damage and warranties, that they’re trying to pick up a lot of things at two years in that they could have picked up free installation.

Yeah. Or lifting of the blades. That world is changing very rapidly. I think a lot of operators are getting smarter about this, but they haven’t thought about where do we go find the tool.

Speaker: Yeah.

Allen Hall: And, and I know Joel knows that, Hey, it, it’s Chris at Blade Bug. You need to call him and get to the technology.

But I think for a lot of [00:06:00] operators around the world, they haven’t thought about the cost They’re paying the warranty costs, they’re paying the insurance costs they’re paying because they don’t have the set of data. And it’s not tremendously expensive to go do. But now the capability is here. What is the market saying?

Is it, is it coming back to you now and saying, okay, let’s go. We gotta, we gotta mobilize. We need 10 of these blade bugs out here to go, go take a scan. Where, where, where are we at today?

Chris Cieslak: We’ve hads. Validation this year that this is needed. And it’s a case of we just need to be around for when they come back round for that because the, the issues that we’re looking for, you know, it solves the problem of these new big 80 a hundred meter plus blades that have issues, which shouldn’t.

Frankly exist like process manufacturer issues, but they are there. They need to be investigated. If you’re an asset only, you wanna know that. Do I have a blade that’s likely to fail compared to one which is, which is okay? And sort of focus on that and not essentially remove any uncertainty or worry that you have about your assets.

’cause you can see other [00:07:00] turbine blades falling. Um, so we are trying to solve that problem. But at the same time, end of warranty claims, if you’re gonna be taken over these blades and doing the maintenance yourself, you wanna know that what you are being given. It hasn’t gotten any nasties lurking inside that’s gonna bite you.

Joel Saxum: Yeah.

Chris Cieslak: Very expensively in a few years down the line. And so you wanna be able to, you know, tick a box, go, actually these are fine. Well actually these are problems. I, you need to give me some money so I can perform remedial work on these blades. And then you end of life, you know, how hard have they lived?

Can you do an assessment to go, actually you can sweat these assets for longer. So we, we kind of see ourselves being, you know, useful right now for the new blades, but actually throughout the value chain of a life of a blade. People need to start seeing that NDT ultrasonic being one of them. We are working on other forms of NDT as well, but there are ways of using it to just really remove a lot of uncertainty and potential risk for that.

You’re gonna end up paying through the, you know, through the, the roof wall because you’ve underestimated something or you’ve missed something, which you could have captured with a, with a quick inspection.

Joel Saxum: To [00:08:00] me, NDT has been floating around there, but it just hasn’t been as accessible or easy. The knowledge hasn’t been there about it, but the what it can do for an operator.

In de-risking their fleet is amazing. They just need to understand it and know it. But you guys with the robotic technology to me, are bringing NDT to the masses

Chris Cieslak: Yeah.

Joel Saxum: In a way that hasn’t been able to be done, done before

Chris Cieslak: that. And that that’s, we, we are trying to really just be able to roll it out at a way that you’re not limited to those limited experts in the composite NDT world.

So we wanna work with them, with the C-N-C-C-I-C NDTs of this world because they are the expertise in composite. So being able to interpret those, those scams. Is not a quick thing to become proficient at. So we are like, okay, let’s work with these people, but let’s give them the best quality data, consistent data that we possibly can and let’s remove those barriers of those limited people so we can roll it out to the masses.

Yeah, and we are that sort of next level of information where it isn’t just seen as like a nice to have, it’s like an essential to have, but just how [00:09:00] we see it now. It’s not NDT is no longer like, it’s the last thing that we would look at. It should be just part of the drones. It should inspection, be part of the internal crawlers regimes.

Yeah, it’s just part of it. ’cause there isn’t one type of inspection that ticks all the boxes. There isn’t silver bullet of NDT. And so it’s just making sure that you use the right system for the right inspection type. And so it’s complementary to drones, it’s complimentary to the internal drones, uh, crawlers.

It’s just the next level to give you certainty. Remove any, you know, if you see something indicated on a a on a photograph. That doesn’t tell you the true picture of what’s going on with the structure. So this is really about, okay, I’ve got an indication of something there. Let’s find out what that really is.

And then with that information you can go, right, I know a repair schedule is gonna take this long. The downtime of that turbine’s gonna be this long and you can plan it in. ’cause everyone’s already got limited budgets, which I think why NDT hasn’t taken off as it should have done because nobody’s got money for more inspections.

Right. Even though there is a money saving to be had long term, everyone is fighting [00:10:00] fires and you know, they’ve really got a limited inspection budget. Drone prices or drone inspections have come down. It’s sort, sort of rise to the bottom. But with that next value add to really add certainty to what you’re trying to inspect without, you know, you go to do a day repair and it ends up being three months or something like, well

Allen Hall: that’s the lightning,

Joel Saxum: right?

Allen Hall: Yeah. Lightning is the, the one case where every time you start to scarf. The exterior of the blade, you’re not sure how deep that’s going and how expensive it is. Yeah, and it always amazes me when we talk to a customer and they’re started like, well, you know, it’s gonna be a foot wide scarf, and now we’re into 10 meters and now we’re on the inside.

Yeah. And the outside. Why did you not do an NDT? It seems like money well spent Yeah. To do, especially if you have a, a quantity of them. And I think the quantity is a key now because in the US there’s 75,000 turbines worldwide, several hundred thousand turbines. The number of turbines is there. The number of problems is there.

It makes more financial sense today than ever because drone [00:11:00]information has come down on cost. And the internal rovers though expensive has also come down on cost. NDT has also come down where it’s now available to the masses. Yeah. But it has been such a mental barrier. That barrier has to go away. If we’re going going to keep blades in operation for 25, 30 years, I

Joel Saxum: mean, we’re seeing no

Allen Hall: way you can do it

Joel Saxum: otherwise.

We’re seeing serial defects. But the only way that you can inspect and or control them is with NDT now.

Allen Hall: Sure.

Joel Saxum: And if we would’ve been on this years ago, we wouldn’t have so many, what is our term? Blade liberations liberating

Chris Cieslak: blades.

Joel Saxum: Right, right.

Allen Hall: What about blade route? Can the robot get around the blade route and see for the bushings and the insert issues?

Chris Cieslak: Yeah, so the robot can, we can walk circumferentially around that blade route and we can look for issues which are affecting thousands of blades. Especially in North America. Yeah.

Allen Hall: Oh yeah.

Chris Cieslak: So that is an area that is. You know, we are lucky that we’ve got, um, a warehouse full of blade samples or route down to tip, and we were able to sort of calibrate, verify, prove everything in our facility to [00:12:00] then take out to the field because that is just, you know, NDT of bushings is great, whether it’s ultrasonic or whether we’re using like CMS, uh, type systems as well.

But we can really just say, okay, this is the area where the problem is. This needs to be resolved. And then, you know, we go to some of the companies that can resolve those issues with it. And this is really about played by being part of a group of technologies working together to give overall solutions

Allen Hall: because the robot’s not that big.

It could be taken up tower relatively easily, put on the root of the blade, told to walk around it. You gotta scan now, you know. It’s a lot easier than trying to put a technician on ropes out there for sure.

Chris Cieslak: Yeah.

Allen Hall: And the speed up it.

Joel Saxum: So let’s talk about execution then for a second. When that goes to the field from you, someone says, Chris needs some help, what does it look like?

How does it work?

Chris Cieslak: Once we get a call out, um, we’ll do a site assessment. We’ve got all our rams, everything in place. You know, we’ve been on turbines. We know the process of getting out there. We’re all GWO qualified and go to site and do their work. Um, for us, we can [00:13:00] turn up on site, unload the van, the robot is on a blade in less than an hour.

Ready to inspect? Yep. Typically half an hour. You know, if we’ve been on that same turbine a number of times, it’s somewhere just like clockwork. You know, muscle memory comes in, you’ve got all those processes down, um, and then it’s just scanning. Our robot operator just presses a button and we just watch it perform scans.

And as I said, you know, we are not necessarily the NDT experts. We obviously are very mindful of NDT and know what scans look like. But if there’s any issues, we have a styling, we dial in remote to our supplement expert, they can actually remotely take control, change the settings, parameters.

Allen Hall: Wow.

Chris Cieslak: And so they’re virtually present and that’s one of the beauties, you know, you don’t need to have people on site.

You can have our general, um, robot techs to do the work, but you still have that comfort of knowing that the data is being overlooked if need be by those experts.

Joel Saxum: The next level, um, commercial evolution would be being able to lease the kit to someone and or have ISPs do it for [00:14:00] you guys kinda globally, or what is the thought

Chris Cieslak: there?

Absolutely. So. Yeah, so we to, to really roll this out, we just wanna have people operate in the robots as if it’s like a drone. So drone inspection companies are a classic company that we see perfectly aligned with. You’ve got the sky specs of this world, you know, you’ve got drone operator, they do a scan, they can find something, put the robot up there and get that next level of information always straight away and feed that into their systems to give that insight into that customer.

Um, you know, be it an OEM who’s got a small service team, they can all be trained up. You’ve got general turbine technicians. They’ve all got G We working at height. That’s all you need to operate the bay by road, but you don’t need to have the RAA level qualified people, which are in short supply anyway.

Let them do the jobs that we are not gonna solve. They can do the big repairs we are taking away, you know, another problem for them, but giving them insights that make their job easier and more successful by removing any of those surprises when they’re gonna do that work.

Allen Hall: So what’s the plans for 2026 then?

Chris Cieslak: 2026 for us is to pick up where 2025 should have ended. [00:15:00] So we were, we were meant to be in the States. Yeah. On some projects that got postponed until 26. So it’s really, for us North America is, um, what we’re really, as you said, there’s seven, 5,000 turbines there, but there’s also a lot of, um, turbines with known issues that we can help determine which blades are affected.

And that involves blades on the ground, that involves blades, uh, that are flying. So. For us, we wanna get out to the states as soon as possible, so we’re working with some of the OEMs and, and essentially some of the asset owners.

Allen Hall: Chris, it’s so great to meet you in person and talk about the latest that’s happening.

Thank you. With Blade Bug, if people need to get ahold of you or Blade Bug, how do they do that?

Chris Cieslak: I, I would say LinkedIn is probably the best place to find myself and also Blade Bug and contact us, um, through that.

Allen Hall: Alright, great. Thanks Chris for joining us and we will see you at the next. So hopefully in America, come to America sometime.

We’d love to see you there.

Chris Cieslak: Thank you very [00:16:00] much.

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits