Weather Guard Lightning Tech

T-Omega’s Solution to Simplify Offshore Wind Turbine Design

Rosemary interviews Jim Papadopoulos, the CEO and co-founder of T-Omega Wind, about their unique floating offshore wind turbine design. Resembling a ferris wheel, the lightweight T-Omega turbine aims to overcome challenges like high costs and difficult maintenance faced by traditional offshore wind farms. Learn about the innovative features of this design and the progress made so far, including the installation of a prototype off the coast of Massachusetts. Visit https://t-omegawind.com/

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Rosemary Barnes: Welcome to a special episode of the Uptime Wind Energy Podcast. I’m your host, Rosie Barnes, and I have with me today Jim Papadopoulos, who is the co founder, chief engineer, and CEO at T Omega Wind. Thanks for joining us, Jim. Pleasure to be here. So T Omega Wind is a unique floating offshore wind turbine.

It’s designed to take advantage of being on the water rather than trying to force an onshore design to work on the water. It’s designed to be lightweight in the expectation that will enable improvements in cost and manufacturability. We’ve actually spoken about Tiermaker on the Uptime Wind Energy podcast before, it was episode 132.

It most resembles a ferris wheel, I would say, if I was trying to find some, yeah, analogy. So it’s got a four legged pyramid frame that supports a rotor in between the two halves. So it’s got, frame on the upwind side and the downwind side of the rotor. Since we spoke about them on the podcast, Hairmaker’s made some progress.

They’ve installed a 1 16th scale prototype off the coast of Massachusetts. And I’m going to ask him how that went a little later on in the podcast. But first, Jim, let’s start at the start and find out your origin story. What motivated you to create a new floating offshore design?

Jim Papadopolous: Well, I have to say, I didn’t set out to say there’s got to be a new one.

And here it is I was entranced by offshore wind. And shocked by the costs. This is first bottom fixed and then floating only slowly. I came to realize that floating is, was really not a product yet, that there are just trials and ideas. But looking at offshore wind, we could see a bunch of things very heavy floating foundations, great difficulty of repair, infrastructure and supply chain needs especially as the capacities kept getting bigger and bigger in a way, because the cost of electricity was high.

So if you make it even bigger than the cost per turbine of the maintenance And the installation doesn’t go up too much. So you actually get more energy for, a lot more energy for a little bit more costs. So there’s discussion of 15 megawatts and 20 megawatts and 25 megawatts. All of which means new generations of turbine technology and it need deeper ports and more metal.

So we looked at all the, all these things and thought, hang on, there’s got to be something better and noodled around until we convinced ourselves that’s something which was shallow draft. And therefore following the water elevation. So wave following and therefore having a lot of motion, which is not tolerant, tolerated by the current turbines.

But if you redesign the turbine, you can get by with this very light, shallow draft platform. And as you’re in the water, you can think about wind yawing to remove a bunch of mechanism. So it’s like that we both, we were appalled by the big costs. We saw something easy to do, and then as we fleshed it out lots of pieces fell into place as a nice system.

Rosemary Barnes: Yeah, right. I’m not sure that I would look at any aspect of designing a totally new I don’t know, in some ways revolutionary design of a floating offshore wind turbine. Easy wouldn’t be a word that I would. associate with that, but you must have a very good team working on it if if that’s an easy challenge.

Jim Papadopolous: Well, we’re naive. We don’t know what we don’t know. So, that’s part of it.

Rosemary Barnes: I think that’s the best way to go into it. Otherwise that, people who aren’t naive tend to. Stick with the status quo because they know it works and they know how many problems you get when you deviate slightly from that.

So, okay. So, I mean, you mentioned some challenges with existing, I mean, not just floating offshore wind, but all offshore wind has most of those challenges, right? I mean, it’s something we talk about a lot on the podcast is in the U S at least the big problems with port infrastructure and the right kind of ship.

And, all those sort of, I don’t know, you might say boring details. If you’re someone like me, that’s interested in turbine technology, you wouldn’t think that you had to worry so much about those kinds of logistics and I guess supply chain is another one. So yeah, are there any more disadvantages that you were hoping to overcome?

Jim Papadopolous: The current design usually needs big cranes. That’s the way people can imagine assembling them. And we would like to say, well, is there a way to do it without a crane? And the current designs are not suited to deep water. And I believe it’s just the cost of the catenary chains at greater depth.

You have three or four whacking great chains at great length, that really add a lot of cost to the mooring. We’re trying to work with synthetics and anticipate being able to go to 2, 000 meters depth. Then there’s the kind of the size of market, the current design with with I don’t know how to put it, with big turbines and with tough maintenance challenges end up with large wind farms.

And so there are going to be markets where you really would only need 50 megawatts, not 500 megawatts. So we can imagine having a few turbines or having just one and quite a bit smaller turbine. So, if you think about scaling down, there are a lot of, there are going to be a lot of places that have water.

And have wind and don’t, can’t work with a one gigawatt wind farm. And we think we could serve those as well as the gigawatt style utility wind farm in shallow or deep water. Yeah,

right. That’s that sounds like a good strategy and I’m definitely going to be interested to hear your solutions for those problems, but I think.

First, we better go back and have you explain what is the T Omega design and what are the, relevant aspects of it that aren’t immediately obvious when, think of it like a Ferris wheel, like I described it.

To talk about one specific size, a 10 megawatt capacity where the hub height for a conventional offshore would be 120 meters.

We have that hub at 120 meters. We have the conventional blades. And then we have a base, which is about 100 meters square, formed of four conical and rather shallow floats. The floats penetrate down into the water five or six meters. So those four conical floats support four legs that all point up close to the same point.

They’re the two ends of the axle, the short axle. And then there has to be bracing between the floats so the legs don’t splay apart. And then that’s a pyramid structure with tremendous structural integrity. Because there are only triangles in the structure, so to speak, four faces that are triangles and then a triangulated base.

And this very rigid and very light structure, And UNLITE is a stand in for saving cost, less material, and it’s a stand in for easier assembly and easier towing. That whole system is going to be moored by a single line, something from a point, something like a trailer hitch on a land trailer. So there’s going to be a point, off, off in front of the turbine, another 50 meters or so, a single point.

And a mooring line will come slanting up from the ocean floor, maybe 45 degrees or 50 degrees. to that point, and the imagined projection of, continuation of that line would go right up to the hub. So that’s a line that points from the ocean floor to the hub. With this arrangement, the tremendous wind thrust on the rotor doesn’t tip the system backwards, but just presses it a little deeper in the water.

And in fact, we will have a separated, but kind of in line continuation of that line as a tensile element between that pitch point. And the hub. So if you stand back, it looks like a single line from the ocean floor up to the hub. Now, when you have an angle like that, 45 or 50 degrees, then when the wind changes direction, you swing in a large circle, depending on how long the line was, which is from how deep the ocean is, and to keep that watch circle to a limited size.

In deep water, we would actually have three anchors and three lines coming up to a point, maybe you. 50 meters below the water surface and that single point below the water surface, a small buoy, will carry the line which otherwise would Be to the ocean floor. So a single line from that buoy and then a rather small circle that it rotates around and the turbine being supported by a single line, like a ship at anchor is meant to be blown downwind.

So it always faces the wind and festooned or kind of looped onto that single line is an export cable. And because the thing may change direction from week to week, we have to think about having a rotary union, an electrical union, so that it could take several swings around, and either, either we let the line wind up three or four times and come back and unwind it, or we have to have a slip ring.

And let’s see what else is going on. We’ve got the shallow floats.

The rest, what you could, from what you could see, there would be the three blades rotating around the rather short axle. And a large direct drive generator is the thing everyone understands, though, in a fantasy of mine, in some future day, we would have a belt drive down to a smaller generator down.

near the water. And one especially important thing to point out is that there is almost no structural mass below the waterline. Whereas conventional floating turbines are like icebergs with more than 80 percent of their weight underwater.

Rosemary Barnes: Okay. And the generator is that special design for It doesn’t look, it’s not that similar to existing wind turbines.

So am I right in assuming that’s a design that you have or will have to come up with on your own?

Jim Papadopolous: Well, the generator, we’re not generator specialists and there are 10 megawatt and 15 megawatt direct drive generators. And we’d essentially be using one of those. Maybe with a slightly different, bigger bore because we have a large diameter axle, but a standard generator, basically.

Rosemary Barnes: It’s got a single connection point. So you’re imagining that this is going to be quite simple to swap them out. Can you explain how you would expect your maintenance to look? And you also, you mentioned that. On your website, at least you mentioned that it won’t need large cranes. Can you also explain how that is?

Like, what is the difference to regular floating offshore wind or yeah, or any kind of, what’s the difference to regular offshore wind and why you wouldn’t need a crane?

Jim Papadopolous: Maintenance is something like a 15 or 20 percent of the cost of electricity of floating wind turbine. So it’s an expense, an expensive proposition.

And we don’t believe it’s safe or a good idea to put people on a turbine that’s bobbing in the waves while the ship is bobbing in the waves. And we hate the idea of having a big crane and needing calm weather to hoist some big piece. So, our notion for maintenance is that since there’s a single point of contact, we like the idea that you can bring a fresh turbine out, we would plan to have one or two extra turbines, they’re not very expensive.

So, bring a fresh one out. When one needs maintenance and swap the rope across, swap the mooring line across and swap the array cable across, which we think if we develop the right technology could be a one hour swap. It’s bringing the towing points of the two turbines close together and swapping the rope and swapping the electric line, taking away the turbine wanting maintenance.

And then once. That’s a shore and we’re aiming to engineer this for easy and kind of rapid towing in almost every weather. Once that leaves, the good turbine is working, so there’s no downtime effectively. And the one we get ashore, of course, you could have a crane. This is an economic question. Do you use the time savings of a crane to justify the cost of a crane?

And that’s fine, but our design is so rigid that it’s ought to be able to be tipped on its side so that the blades are near the ground and that tipping is a, should be a two hour winching operation or something. So we have a, an elaborated scheme, both for assembly and then for disassembly and maintenance that assure it can be tipped.

Thank you. You can reach the bits you need, replace the parts you need, replace anything, take fresh parts from stores and refurbish the old parts later and tip it back up and tow it back into the water.

Yeah, even for fixed bottom offshore wind, maintenance is the huge thing. I mean, the industry itself is still young, so, we haven’t really had a lot of time to see what the.

The true reality of maintenance is going to be not just for the average, but also for the, like, worst five or 10 percent of wind turbines, that makes a difference if you’re going to have long downtimes. And if you’ve got to get personnel out to site every day in a boat or a helicopter, then you can just imagine how much that adds costs if you’ve got your turbine shut down the whole time.

So I can a hundred percent get on board with the concept that you have for maintenance of. Yeah, being able to bring it to shore so that you bring the turbine to the people and yeah, potentially even having a set of spares there so that you can keep things going with the spare turbine while you work on the new one.

I guess that’s going to depend on if if you’ve got space at port to store that and you’ve got the extra money to keep it there, but yeah, like some of the. The floating offshore wind farms now are looking at six months or so of downtime while they fix the issues that they’ve got. So, like you can afford a spare turbine if you’re, if that’s the alternative.

The

parameters that will go into estimating downtime include things like the towing speed, the swapping speed, and then maybe the disassembly time at port and we’re, and we’re really looking for order of magnitude improvements compared to what any what’s predicted for a semi sub.

Rosemary Barnes: Okay. So that all sounds great. Definitely. Very good on, on paper, but on paper is not what we need. We need, actual turbines out in the ocean generating actual electricity. So can you tell me a bit about how far you are along on that process?

Jim Papadopolous: There are a lot of things we don’t know. And for example, our, there’s a, the certification process as we understand it through DNV would involve normally.

Giving everyone a good feeling that you could manage a 25 year fatigue life or something. There’s a lot of calculations involved in that. And we’re upending that thought and saying, well, what if it’s only a three year fatigue life? Of course, I’m only saying that as an unlikely extreme case.

The main idea is that instead of aiming to last a really long time, we expect to replace components as needed year after year, like car parts. So we that’s kind of the beauty of many trips ashore and easy going ashore. And I do, I hope the structure has a lot of air galleries such that with a little bit of air pressure, you can tell if there’s a crack growing somewhere because it leaks.

And so, we’re thinking, well, let’s design for a three or four year life. And so the DNV folks say, hang on, we have to do a study to know what kind of validation we’re going to need. So, right at the beginning, we’re stuck on now knowing exactly what to do. We don’t know exactly what to do.

So we’ve, the very, the most unusual aspect of our thing is the geometry and the mooring and the shallow draft. So we’ve been looking at the hydrodynamics, which means, you get something more like that and then big waves come along and does it tip over? Does it leap out of the water? Does it swing crazily?

What happens? And so some of our study was in wave tanks. We went to Glasgow and we had one at the University of Rhode Island. Look, looking at the largest waves they could supply, which scaled would be, it would be like 30 meter waves in 120 meter, tower hub height. And we saw, kind of beautiful behavior.

And then we’ve been using this program called Open Fast, which is developed by the National Renewable Energy Lab. And it’s considered one of the better programs, and it has all kinds of hydrodynamics and wind forces and mooring forces. And so we’ve kind of tuned, they adjusted the software to work for us, the added features.

And then we’ve been exercising the software and as you must, you look and see it, look at the results and hope that nobody put a minus sign in the wrong place. And we, it all looks reasonable and therefore, yes, with the open fast work coming at it from several angles, very nice behavior in large waves.

And we’ve just started the work of with a wind thrust. Due to energy production and also in a storm case with a wind drag, not a rotor thrust so much so that kind of numerical work which we, it looks similar to the wave tank work. So, we’re, we’re always looking and trying to decide, do we trust it?

And how far can we trust it? And what does it mean for the design? And then we want to change the design. So, in this and OpenFAST work. We saw, we had a look at something with a 70 meter base, and my understanding of the hydrodynamics is it might work better if it was a 100 meter base, so we swapped the model.

And indeed, there was much less hub acceleration, and there was less bending moment in the towers, and bending moment in the braces. And there were lower slamming forces on the floats with this 100 meter base, so that was an inspired guess that seems to be okay, and now we’ve looked at the weight and so forth, and we’ve been trying to we’ve been trying to suit the design to to tolerate 50 year storms in the North Atlantic.

Such that, what’s the biggest bending moment you expect in a three hours, fifty, three hour, fifty year storm of this or that peak period, wave period, and significant wave height. There’s an environmental contour we’re using. And so, yeah, it’s way better than just guessing, but it’s not proof.

And so, this this OpenFAST work has to continue, and the structural design has to be what’s the word fleshed out to suit those loads, at least for ultimate states, and we have to then decide What does it mean for fatigue and what kind of life can we really work with? And I’m saying for some parts, maybe as little as three or six years.

Rosemary Barnes: Yeah. Okay. I mean, I’m assuming that would be an initial lifetime as you learn more about it, then you would be able to improve the components that are wearing out in three to five years. Right. Cause you could, because the the cost of the turbine is so small compared to the total cost of the wind farm.

Is that why it doesn’t matter? Well,

Jim Papadopolous: I, in my costing, I figured, I just imagined replacing every part of the structure over 10 years, and that was a good cost. So it’s just that if the maintenance is simple and cheap, then have more of it. That’s kind of, kind of my simple minded thinking.

But so all, the design has to be elaborated and studied with greater fidelity, I guess, is the point. And we have to, we found a problem with wind alignment, because a turbine, an operating turbine does not work like a ship at anchor. There’s something we didn’t know. So it’s not that the thrust force on the rotor is downwind, the thrust force is normal to the rotor.

So it doesn’t really self center when it gets off axis. And so the NREL put in a model of individual pitch control, which they have in their controller that they built for us. And that can, if the thing has swung away from alignment with the wind, which it would at certain wind speeds, it can be returned by adjusting the pitch, once per revolution, like a helicopter rotor, to get the center of pressure off one side.

So, so, so there’s the, so there’s the structural work. There’s the kind of the energy harvesting work, there’s the stability when energy harvesting, we have to look very much at the towing, at the swapping, at the at the erecting. So there are a lot of questions, but probably I would say that the open fast work and the wave tank work should give people confidence that it’s not, it doesn’t look like a disaster straight off so that we should get funding to work on something bigger and higher fidelity.

Rosemary Barnes: A couple of good things that I can see in your development approach is one, going and test testing out interesting things that you’ve seen in the simulation and yeah, making sure that they broadly make sense and to using the open fast software, which is developed for wind turbines and has been validated against, no wind turbine exactly like yours, but at least for wind energy.

So I think that puts you definitely a few steps ahead of where you would be if you had done what seems to be the typical thing of just, yeah, grabbing a Ansys license and and having a crack at a model, which you definitely do. And you can definitely get nice colorful graphs that will probably get you investor dollars, but you’re also in for a rude shock when you build something.

Jim Papadopolous: We’ve been very lucky to work with the NREL folks because they’ve. They’ve sort of attacked all kinds of problems in all kinds of directions, and they aren’t in the business of putting out a specialist thing that gives one clear, beautiful answer, and then you’re done. They’ve worked with, all the gusty winds and all the spread spectrum sea states and this, that, and the other, so We have we’ve, one thing we’ve done is we’re using known naval architecture spectral techniques to estimate the worst case, either bending moment or acceleration or float lift in a given sea state.

And we trust that these are done. This is a good approach. And so we’re using the RAOs. That NREL can give us for all kinds of forces and moments and so forth. And so we like that. We’re going to back that up with the kind of the nonlinear simulation in the same C state to see that it does more or less match.

And then we have, we’re trying, we want to compare the wave tank results to the NREL model as if placed in the wave tank. We haven’t done that yet, but we want to make sure damping looks about right so that a lot of things we want to do to make it right and to do the kind of robust. And, highly varied loading that was called for.

So that’s enough for now on that.

Rosemary Barnes: So I am really keen to hear about how the different phases of development have gone and how long you’ve spent on it. Like how, when did you first start working on this and what kind of a team did you assemble? What backgrounds do you have people from oil and gas industry?

From academia, from the wind industry, how did that start out?

Jim Papadopolous: So it was, it started off with just another professor and myself. I was a lecturer and he was a proper professor at Northeastern University in Boston. He’s been doing work on wind turbine, offshore wind turbine towers, bottom fixed, doing the research and the loadings and so forth in the environmental conditions.

And when I When we made friends and I started telling him my ideas about floating, he liked them. And so we, I think we got a couple of small grants, just working on an idea. Then we formed a company, I think around 2020 incorporated and. Invited people in, we got three very talented people. One of them was a serial entrepreneur and he had a small wind turbine company.

He’d been in offshore oil work for a while. He’d been, he’s a patent attorney. He’s a, an MBA, he’s a tugboat operator. He’s a pilot. He’s a, he’s sort of done everything. Yeah. He’s a very versatile guy. And we need, we needed good IP advice in the company. And then we hired a woman. She had been she had started her career at Equinor, the Norwegian woman.

And she ended up, she got educated in the States and got a business degree and she ended up at Duke. She was at Exxon for a while and then at Duke Energy in the U S for 20 years. And, kind of a fairly senior executive who wanted to get into something clean, as opposed to Duke’s world of coal and oil.

And then we have Dave Forbes, who was a venture capital, he was in politics for a while, helping various presidential and govern, gubernatorial campaigns. And then he was at a venture capital firm, maybe in Hong Kong or somewhere. And so he’s. He’s our outward face to try to get investment because he knows it from the inside.

And so all those people came, we formed the company in 2020 and those people came on at sort of half year intervals and now it’s just turned 2024.

Rosemary Barnes: And they brought with them funding that enabled you to build this 1 16th scale. No. How did you come by the funding to buy your, to, yeah, to build your 1 16th scale prototype?

What, how did that come to be?

Jim Papadopolous: So what happened is we’ve had a few, we’ve been in a couple of accelerators where you get 20 or 50, 000 or 100, 000. And then we got a, an STTR grant from the National Science Foundation that’s You may have heard of it as an SBIR grant. That was probably 250, 000 and let us get the NREL work done.

And then the state gave us a matching, a 50 percent matching grant, 120, 000, and that let us design, build and launch this prototype.

Rosemary Barnes: And so it was recently that you put that prototype in the water and then I saw news reports that it was removed early. Can you tell me a bit about how that experience was getting it in there and yeah, what its short life in the water was like and what’s next for the company?

Jim Papadopolous: Well, we were hoping for a two month trial. That was what the permit is for. And we wanted to have. The wind thrust and the torque of a low, of a, we didn’t have a generator, but we have a pump, so it was going to make power, and we were going to then get the sort of the hydrodynamics with the thrust force, in the given sea states, we wanted to see the orientation to the wind, we wanted to see the RPM, the rotor went, we wanted to see all kinds of things like that, but it turned out that the data acquisition wasn’t working, and also that there was no drag torque on the rotor.

This is something was installed backwards. In the installation that day. So it needed to be tweaked and that never happened. After some internal debate, it was pulled out of the water and taken to bits.

Rosemary Barnes: All right. So it’s there on, on ice until you’re able to, in storage waiting for another. For repair and waiting for it to stay back on the water.

Jim Papadopolous: The repair is trivial. It’s waiting for the group decision to put it back in.

Rosemary Barnes: I will be interested to see how that goes because it’s a really common story where, you know, a great idea, a great product, it, there’s always some frustrating mundane or, interpersonal problems that end up, you causing big issues for our product and.

It’s yeah, it’s not just sad for the individuals involved. It’s sad for everybody that wants to see great renewable energy technologies. So, yeah, I will be definitely rooting for you and following closely. Thank you so much for talking to us about Tia Omega and yeah, I’m wishing you the best of luck for the future.

Thank you, Rosemary. Thanks for listening and please give us a five star rating on your podcast platform and subscribe in the show notes below to the Uptime Tech News, our weekly newsletter. I’ll see you in the next one.

Renewable Energy

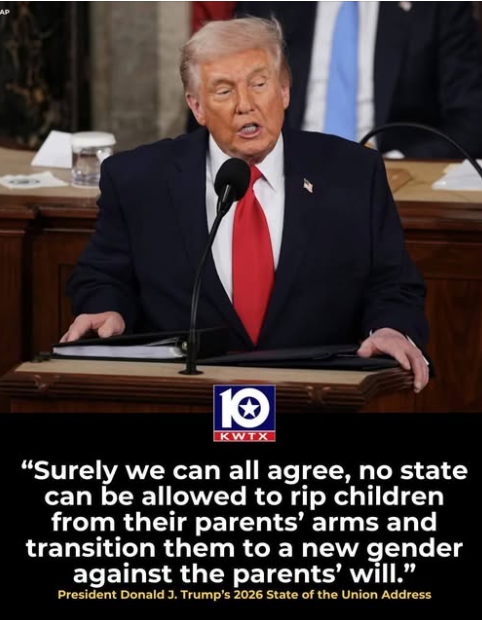

Forced Transgendering of America’s Little Kids

How often does this happen? How about never?

How often does this happen? How about never?

Trump loves to say that little boys go to school and come back home little girls.

He’s the most powerful person in the world for exactly one reason: We’re a nation of morons.

Renewable Energy

Illegal Aliens and U.S. Veterans

Two comments:

Two comments:

That the United States has homeless veterans is a national (and international) disgrace.

By definition, no one has the legal right to enter the U.S. illegally, but according to our constitution, everyone in America is entitled to due process.

Renewable Energy

Cancelling Renewable Energy

This will result in lung disease, climate change, loss of biodiversity, and higher electricity prices.

This will result in lung disease, climate change, loss of biodiversity, and higher electricity prices.

It will also further alienate the rest of the world from our country, as every other nation on the planet is making gains in the direction of decarbonization, and no other nation suffers from this level of corruption with the fossil fuel industry.

If that pleases you, you’re a warped human being.

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits