Weather Guard Lightning Tech

Blade Repair Academy’s Expert Technician Training

Blade Repair Academy in Tennessee offers comprehensive blade repair training programs for technicians. Alfred Crabtree, Founder and CEO, and Sheryl Weinstein from SkySpecs highlight the importance of technician competency, hands-on experience, and standardization in the wind industry.

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Allen Hall: Alfred and Sheryl, welcome to the program.

Sheryl Weinstein: Thanks.

Allen Hall: So we’re in Dunlap, Tennessee, not too far from Nashville, uh, and also close to. Chattanooga Chattanooga, and we’re in the Smoky Mountains ish region.

We’re

Alfred Crabtree: no, we’re, we’re, you could consider it Appalachia for sure. Sure. Okay. Uh, we’re on the, in the valley called the Seche Valley, uh, which splits the Cumberland Plateau. So we’re, we’re in a valley and we have hills a thousand feet above us here. Yeah. Either way. It’s beautiful.

Joel Saxum: Yeah. It’s a great drive in here.

Alfred Crabtree: Yeah. It’s a unique place. Yeah.

Allen Hall: And we’re at Blade Repair Academy, which, uh, if you’re not familiar with Blade Repair Academy, you should be. Uh, because a lot of the good training that happens in the United States actually happens to play repair, repair Care blade, repair academy. Uh, yeah, it’s been a long week at uh, OMS this week and we got the introduction today.

This is the first time we’ve been on site. That’s right. And, uh, we wanted to see all the cool things that are happening [00:01:00] here. And it really comes down to technician training competency. Working with blades, working with tools, knowing what you’re doing up tower when you’re on the blade, which is hard to train.

It’s really hard to train, and both you and Cheryl have a ton of experience being up on blades and repairing blades and scarfing and doing all the critical features that have to happen to make blades work today. It’s a tough training regimen. There’s a lot to it and a lot of subtleties that don’t always get transferred over from teachers to students unless you have.

Done it for a number of years. You wanna kind of just walk through the philosophy of Blade Repair Academy?

Alfred Crabtree: Yes. The, uh, you’ve, you’ve outlined quite well some of the issues. The environment where we work is very hard to take a ti the time to put somebody through a training regimen. We’re so constrained by weather windows and then.

You know, even if the weather’s nice, lightning can come, wind [00:02:00] speeds can cut off your workday. So production, production, production is what’s important. And Cheryl and I both come from the rope access method. And in the rope access method, 95% of the time you’re up there alone. And if you’re up there and you’re producing, you’ve got your blinders on.

Speaker 2: Mm-hmm.

Alfred Crabtree: And you’re not ready to share with somebody else what to do.

Speaker 2: Mm-hmm.

Alfred Crabtree: With the basket or platform, you can have two even three people up on Blade, but it still has all these constraints of get the job done, get the job done. There’s a lot of stress up there. And having the bandwidth to take on new information or to challenge some preconceived notions or try, that’s not the place to do it.

So knowing that. Blade Repair Academy is built so that we have an environment that simulates all of the up tower stuff without being up tower. And you’re gonna have the time you need to invest in your learning without consequences. Right. So it’s a very much a [00:03:00] about creating the right environment to uptake the new information.

And we have found a lot of help from. Manufacturers and suppliers in the industry to sponsor us because obviously it behooves them to have their materials in the hands of trainees. So we’re also able to help companies come up with, uh, new solutions, try new products.

Speaker 2: Mm-hmm.

Alfred Crabtree: New, uh, you know, what’s the best practice.

For this, if you’re up on Blade and you have a way of top coating and you get a new product and your way of top coating doesn’t suit that product, well chuck it down. I’ll never touch it again. Yeah. Because I did not perform well here we can, we can give you training. We have, of course, been trained by the suppliers about what’s the best product to use, what’s the best way to go about things, and then, and then we can disseminate it.

So that’s the fundamental reason why the space is. Is [00:04:00] what it is.

Joel Saxum: Yeah. And I think that that’s, that’s a good segue to be honest with you, right here, right behind these doors you have a classroom. That’s right. Right. So in this facility, all composed in one, we have a classroom here we have your additive and subtractive.

I liked how you said that to us when you’re giving us the tour. Uh, but we’ve got a, a grinding booth basically over here and we’ve got, um, a layup area here where you can teach. 16 people at a time.

Alfred Crabtree: That’s right. Yeah. That would be max

Joel Saxum: for sure.

Alfred Crabtree: Yeah.

Sheryl Weinstein: And in a vertical surface, so, ’cause all the stuff that you’re doing in the field, right, is always in a vertical surface.

Mm-hmm. So there’s a, there is a big difference between working where gravity is sort of against you, especially with larger laminations and things like that. So being able to do your training and simulate the same, a similar way that you would work in the field is pretty critical, I would think.

Allen Hall: And actually working on.

Actual repairs. Simulated repairs, yeah. Mm-hmm. Now, don’t explain how you created them, because I know secret sauce. It’s a secret sauce. Yes. But I did look at the blade [00:05:00] damage. It, it looks exactly like a lightly strike. Yeah. Which a predominant amount of repairs are about, unless there’s, you know, serial defects, as Cheryl has pointed out numerous times, but.

Being able to repair something that’s quasi real is critical because we’ve been to other places and the repairs are, well, I’ll take a hammer and I’ll hit this and, okay, sure you got a DA, you gotta repair that. But that’s not real. And getting, getting the people to use the tools in the right way, vertically

Speaker 2: mm-hmm.

Allen Hall: Is the key. Because although the, the, the article, the test sample isn’t moving around like you are up on a blade, it’s still difficult. And unless you have the proper techniques and the approaches, yeah, it’s gonna be dang near impossible. We explain some of the blade repairs that Joel and I have seen more recently is like.

It’s a little rough and it shouldn’t have to be so rough because it is a skill that you have to learn and acquire over time. But you have to know the fundamentals. That’s what Blade Repair Academy is here to teach you those [00:06:00] fundamentals. Like, yes, it’s gonna take time, but if you work it this way, at least you’re gonna be successful.

Alfred Crabtree: Yeah. And if you’re managing a team of employees who are doing this, it, it would be great to have the insight of what your teams. Strengths and weaknesses are, yeah, you can figure out how to deploy people, but also how to, you know, maybe fix some of those problems. Mm-hmm. Our panels that you brought up are standardized.

Everyone looks exactly the same. It’s the exact same makeup, and we standardize the damage. So when somebody has to repair damage here, the core removal size is the same on everyone. That way when we’re comparing the reports, you can actually have a apples to apples comparison of the, the trainees. Outcome.

Speaker 2: Mm-hmm.

Alfred Crabtree: And now you, you know, in, in the model that you talked about where people will go to a, you know, their junkyard of blades and they’ll find spots on blades to put their eight guys on. Those eight people are not gonna be doing the same repair. And even if they are collecting data, what are you [00:07:00] comparing?

It’s not

Joel Saxum: apples to apples. Yeah. It’s not.

Alfred Crabtree: So we really tried to start from the beginning, fresh with a whole new idea of how to approach this. Mm-hmm. By not being attached to an ISP, we don’t have to deal with. Oh, here, use all our leftovers. Yeah. Yeah. That’s your training budget. Yeah. Yeah. And oh yeah. We, you know, we’re an, we’re a owner operator, so yeah.

Go work on that blade in the grass. Mm-hmm. That those limit what precious time we have available to train. Yeah. So this thing from the ground up is about. Making as much advance in the skillset and understanding that technician in the, in the week that they’re here.

Joel Saxum: I think that was a really cool thing we touched on as well.

Your, your team here as well, Cheryl. Thanks for traveling up to, to hang out with us. Offer some insights too. But you guys, because you’ve been in the people that have developed a curriculum yourself, Cheryl, your, some of your team sitting over here, uh, and, and people around the industry that have helped out with the place, you have the ability of like, okay, we have.

Eight brand new technicians. Let’s make [00:08:00] sure we walk through how to measure from the trailing edge to the blade center up, mark this thing out, these kind of things all the way to some stuff that I didn’t really think about that much. Like I’ve used an angle grinder before, right? But I’ve never looked at five different ones and decided which one would be the best for my hands.

Thinking about it up on the blade, how you’d handle it with your fingers, these kind of things like, I was like, man, that’s, those are real insights that you’re not gonna get to learn. Like why put someone up to let them have a whole season or a whole summer, two summers figuring out how to hold a grinder?

Well, when they can learn from someone that’s been doing it for years and years and years and can teach them these things. So from advanced or from very beginners learning fundamentals to advanced training, you guys have gotta cover here.

Alfred Crabtree: There’s something here to glean for everybody, and even if you are a well experienced technician, maybe what you’re gonna get most is learning how to talk the language of the new techs and the new hires who are getting the.

Introductory course training. You know, our, our el our basic course is called support. It’s 40 hours [00:09:00] and it’s really about making, uh, an employee who can support a lead. And then if that person follows up with the lead training in a whatever interval of time of their choice, which is kind of another benefit here, we can train you any week of the year.

That is where we start to really get this, we call it the retention vortex. Right where we layer up technician training and somebody who’s had level two now gets a level one with them. Now there’s some synergies. Now they’re getting some really efficiencies. A commonality of language, a commonality of process, you know, eliminating variables.

Uh, and that’s how you’re gonna have to build new net capacity and build new teams

Allen Hall: and that common language. Is really unique, but that comes from your experience in the field, mostly at rope partner, where you both really got your teeth in this industry.

Speaker 2: Mm-hmm.

Allen Hall: But communicating to one another correctly so you can pass along to the next crew or even explain what you did to the engineer, the.

Properly [00:10:00] there is. There is a culture to it. There is a language to it, and you just don’t pick that up. By going from wind turbine to wind turbine. You pick it up in training from someone who knows how to do it. It’s really critical.

Sheryl Weinstein: It’s pretty critical to have baseline training. I think it is also very important to follow it up with field experience and skills building because every blade model is different.

Every repair is different. You’re always gonna encounter something that deviates from that like standard approach to your repair. You have to kind of know how to problem solve, and that kind of only comes with the field experience, but having a more standardized training to start with, it’s something that industry doesn’t really have and is really needed.

I think across the board it also helps, you know. Owner operators or even OEMs kind of track their ISPs and understand what level of text do you have, what experience do they have and how, how does that differ across their different [00:11:00] levels? If we have one ISP training one way over here and another one training another way over here, and they have different sets of certifications.

It’s really hard to keep that all together and evaluate it as an owner operator or an OEM, you know, using a vendor. So I think having a place like Blade Academy that’s agnostic and separate from like, you know, the actual ISP really helps to standardize that a bit more.

Allen Hall: Yeah, because the key is we’re getting to, well, we’re gonna cross a hundred thousand turbines in the United States pretty quickly.

Yep.

Joel Saxum: Before 2030, or probably rated about 2030.

Allen Hall: Right. That’s. Soon. Mm-hmm. How are we gonna manage that? And there’s a lot of new people coming into the industry, obviously. How are we gonna train ’em up properly? How are we gonna communicate to one another? And there’s just so much movement in the industry. I.

It makes it hard, I think, because weirdly enough, I think ISPs develop their own little culture about how to deal with things, and then they hop to the next company and it’s a different language. Exactly. And that needs to go away. Yeah. There’s a,

Alfred Crabtree: there’s a branch of business that’s [00:12:00] OEM centric and there’s a branch of business that’s asset owner.

Yeah. Post warranty. And those are really two different things. And, and there’s a veil of secrecy between one and the other. Yeah. And we kind of feel here at Blade Repair Academy that we’re like this polyglot that can talk to everybody because we don’t have, we’re not an ip You’re not competing, we’re not an O You’re not competing.

Yeah, we’re not competing. But we, we, you know, we have the, we wanna provide this data as a clearinghouse. You know, we talk about certification in the non standards. Well, the way we deal with it is we’ll give you a certificate. And it’s got our brand on it. But you know, what does that mean? Yeah. What? That And $4 will get you a Starbucks the way we do it, maybe not even then.

Right? The way, the way we, not four bucks

Sheryl Weinstein: for Starbucks, maybe 10

Alfred Crabtree: and a half hour wait in the line. But the way you know, what we do is we provide you with a deliverable. We knew, we knew that. Okay. Our certification is, you know, ether.

Speaker 2: Mm-hmm.

Alfred Crabtree: But [00:13:00] this report. That everybody who comes through here generates that you can compare.

Now you’re gonna have to go to work and study these reports when you get ’em as a deliverable.

Speaker 2: Mm-hmm.

Alfred Crabtree: As a, you know, an employer, but we we’re giving you what you need. Mm-hmm. To make some decisions about what do I have to work on, what else do we need to improve upon?

Allen Hall: Yeah. Not everybody’s built for this job, but you wanna be able to suss that out.

Earlier rather than later. Yeah. Right. I mean, there’s other things to do with wind turbines that don’t evolve blade repair. And if they don’t necessarily have the skillset or the comprehension to do some of these more complex things, maybe blade repair is not it. Right. But rather know that now. Yeah.

Right. And the Blade Repair Academy is a place to do that because there’s a standard there, right? Mm-hmm. And I, I, as Joel has pointed out, yeah, there’s a lot of erratic training that goes on. Mm-hmm. You can’t compare student A to student Z. Blade repair academy. You can.

Alfred Crabtree: We can. Mm-hmm. Right.

Allen Hall: And if, if I’m an ISP, I want that.

Sure. I want you to tell me [00:14:00] who’s on top and who’s kind of the middle so I can make decisions about where to deploy ’em and who and who to put ’em with.

Joel Saxum: Yeah. ’cause at the end of the day, every ISP, uh, every ISP that’s trying to grow and scale effectively is trying to do that at the end of the year, right?

Yeah. They’re looking through, they’re grading their technicians, finding out who’s the next lead, who’s this, who’s that? But this is a great way to do that, sort them through in a controlled setting. I mean, we sat in, in your training facility in the actual classroom here, and you walked us through some of the online, the online training platform that you have built.

Some of the things the students have to do before they get here, and then kind of how you walk ’em through things, and it’s impressive. It’s good stuff, right? So when you have that combined with the both sides of blade repair, subtractive, additive, right? You get to get this, this holistic view of what that blade technician can do.

Yeah. Right? And that’s, that’s one of the things you guys offer here, which I think is fantastic.

Alfred Crabtree: Yeah. And we’re trying to constantly improve, you know, we’re talking with OEMs about dissemination of operating procedures or work instructions, share with us [00:15:00] work instructions. We’ll build analogs. That we can train to.

Mm-hmm. And we can test off of it. We can verify skill sets. You know, we have a lot of serial flaw campaigns out there that are critical. And do we wanna unleash anybody on it or do we want to know that those people can do it? I think everybody wants to know that they can do it, whether they’re the.

Technician themselves, or the person writing the checks.

Speaker 2: Yeah. Mm-hmm.

Alfred Crabtree: Everywhere in that loop wants to Now not everybody wants to pay for it. Yeah. But we all need it.

Speaker 2: Yeah.

Alfred Crabtree: And so somewhere along the line, you’re paying for it in the forms of our favorite acronym, COPQ. That’s

Joel Saxum: right. Cost support, quality. You know, speaking about the idea of serial defects or known problems in the industry and how to prepare people for those, how do you prepare people for those?

Well, they gotta get the experience by just. Grinding away Top coat and getting into him. I walked in here and I looked at this blade sample we have here, and I was looking at it and I go, it looks like a 48.7 C Oh yeah. Buddy walks over you like our 48.7 C I’m like, [00:16:00] man, you guys did a good job on, you know, like, so, so I made a lot of money on 48.7, you know, so to walk in here and see these different tickets that you guys have built, you know, carbon plank and different things with carbon spars and hey, we’re gonna do a carbon spa repair.

We have this boom, now we can work on it. Mm-hmm. You know, and we’ll

Alfred Crabtree: work with you to solve your problem in a really quick, efficient manner. Mm-hmm. You know, I think one of the things that we have is operational readiness. Most people who are training in-house flip their hat around for a couple weeks and train composites.

Mm-hmm. In a limited capacity in the warehouse or at the dock at the truck during January. During January, whatever. And then they flip their hat back on and they go deal with it. And I think the hiring situation is so tough. Like working at Height, you probably need to make sure somebody can tolerate working at height.

Yeah. Before you invest in composite training, I mean. You have so many things you have to juggle in your particular situation. When do I put money in this person? We get that. [00:17:00] And so we’re open all the weeks of the year. So we can do this at any time. Of course, everyone wants it in the end of first quarter.

Mm-hmm. You know, right before the season starts. So we have a, you know, you have to, you gotta schedule with us, but we can really do this anytime. And so you don’t have to one and done and live with it.

Speaker 2: Mm-hmm.

Alfred Crabtree: You know, it. You can fit the training into your hiring schema wherever you feel fit, and you can hire people.

And if there are stars, bring them in for their secondary, they’re execute their lead training whenever you want. You know, so you can, we can be very flexible and in the advanced stages we will make what you need, you know, obviously has to make business sense for us, but we’ll make blades to replicate the problems you’re facing.

Sheryl Weinstein: And I think in terms of like what you were saying when you’re working on, you knows whether we wanna call them recurring issues or serial defects. A lot of it is awareness, right? It’s awareness [00:18:00] of understanding the blade structure, at least at a basic level. It’s awareness of understanding what you’re looking at.

It’s, you know, we’re only gonna better inform the industry and the OEM if our technicians have a level of awareness to sort of bring up things that they see as they’re doing repairs. So if they notice that, for example, the, the fibers are misaligned, right? That could indicate that that was a wrinkle, and them having that level of communication or documentation will only help then inform the OEM.

Like, is this the reason behind that problem? And so I think like. You know, with Alfred and, and the curriculum here at Blade Academy, them kind of, you know, setting a standard for how, how you know, the structure of the blade, the different types of blades you may see, whether they have carbon fiber in them, or you know, fiberglass, UD spars.

Where those things are located, [00:19:00] what to be aware of as you’re removing damaged material. It’s really critical to the overall quality and just the awareness of the tech on the blade and that feedback loop that we’re lacking so much in this industry.

Alfred Crabtree: Yeah, for sure. Yeah, and we have our boilerplate products that come from, you know, like, uh, Cheryl was my mentor at RP and wrote partner, and she taught me a lot and a lot of the.

The, the way we do things here comes from the rope, a rope access paradigm, which, you know, actually is backward compatible because if with rope access, you’re doing things alone.

Speaker 2: Yeah.

Alfred Crabtree: So if we’ve have ways and, and processes that allow that to happen alone, then when you’re on a basket or a platform with an extra person, you can only benefit Yeah.

That much easier. Yeah. Um, it’s where we come from, you

Joel Saxum: know, and, and that’s a good point, right? Like when we’re sitting here, rip Blade Repair Academy. Alfred, you’re here. Cheryll, you’re joining us today. These are two X blade technicians that have been on all kinds of blades. They have been up and down on ropes.

So it’s training by [00:20:00] trainers who have been the technicians that’s important. Who have seen the problems. Yeah, yeah. You know, who have lived, have lived that road life. We talked, you’re joking about living in hotels, right? Mm-hmm. Like that have done, gone through that, right? So you’re learning from people that aren’t just like, oh, I hate the idea of going to a university and learning HR or something, whatever, from someone who’s never done it in the real world.

Yeah. You know, uh, the trainers here have done it in the real world, um, and it shows.

Alfred Crabtree: Thanks, man. And you know, the other thing too is our tagline is practical and contemporary. And the thing is, I’m no longer contemporary. Like I left the field years ago. I rely on folks like Cheryl, who’s still in the, in the Blade Services game over there at Skys Specs.

She’s on, she’s got a full subscription to the cereal floss that are out there.

Joel Saxum: Yeah. Probably the best one in the industry, to be honest with you.

Alfred Crabtree: Well, you know. Uh, I think so. I don’t know anything about serial flaw, but it’s, it’s input from the rest of the industry that’s gonna allow this to continue.

Otherwise, we’re gonna be, you know, [00:21:00] a 10-year-old standard that isn’t relevant anymore and that’s not what we want to do. So, outreach like Cheryl and I are talking about, Hey, what is it in your product line that should be in our product line? And I want to talk to OEMs and, uh. Owner operators, you know, what is it?

What are your pain points? What in your fleet is needing attention? And of course, we’re gonna do all this with the business case, right? Mm-hmm. Like we wanna take LEP products and place them head to head and give a two day clinic or seminar to stakeholders, to purchasers. You know, we wanna give our, our two, our five day course condensed into two days.

Where people who are stakeholders who are making decisions about where to place technicians, they should get out here and gr and grind a little bit and get a little empathy for their position. Hard work. The hard work of the

Sheryl Weinstein: hard work that it is. Yeah. And then kind of understand

Alfred Crabtree: from another side where the [00:22:00] communication breakdown is.

’cause it’s, it’s not all the texts, right? Mm-hmm. You know, they have a, you gotta understand how heavily loaded they are, you know, when they’re in the field. Mm-hmm. Um, so we’re, we’re at the place now where we’re really looking to do some outreach and talk to, uh, regulatory bodies that are starting to come up with standards, right?

Like the IEC group met and pro produce a draft standard and they’re gonna work on the repair standard. And that’s a, a little bit of a ways away, but I can’t sit around and wait for, for standards to come to me. So we got this thing started. If you build it, they will come. You guys came, you know, Cheryl came and, um.

We we’re really proud of where we’re at, but at the same time, it’s like, okay guys, the rest of the industry, now we’re here. Now you need to know, now you need to take advantage of us. Mm-hmm. And help tell us what you need. So I think the

Sheryl Weinstein: LEP thing is a really good call out because I do see a lot of customers questioning what do I choose?

How do I know [00:23:00] what to choose? Absolutely. Should my vendor be telling me what to choose? And that’s what happens in many cases, is that the ISP just kind of tells the owner operator. This is what you should use. Well, why, and, and what, you know, how have we ever really sized up like one against the other?

Like in any true, I don’t know, study? No. And a lot of the, a lot of the like. Those different types of LEP, the, the companies that you know have these, they don’t have a lot of good documentation on showing like how their products stand up. I mean, it’s kind of, it’s more theory based than anything. I mean, they put ’em through rain erosion tests and whatever, but.

It’s, I feel like that’s a tough space. It’s also a very, like, um, a very tough scope of work to have high quality at. So more training around it is necessary. You know, repair companies don’t wanna use their high skilled repair techs for the LEP because they need them for the more complex repairs [00:24:00] yet. The LEP is so susceptible to quality issues, and if you’re gonna pay an extreme amount of money to, you know, put the LEP to fix your erosion, put the LEP on blades, hope for a performance improvement, and then it fails in a year.

I. That’s no help to anybody. So these different products, they also come with different price points. Like, can we really value the shell over the coating? I, I just find that this is a tough space. And so doing something like that and doing more training around LEPI think is probably pretty important. Yes.

You know, unless the robots are gonna take it over and then, well, even then, I think it’s the only app.

Allen Hall: The application, that’s the variable there. And not having people trained up for that particular LEP product is a huge problem because it’s super risky. You’re risking all that money and time and having to do it all over again and removing LEP that has been improperly applied.

It’s a nightmare. [00:25:00] Nightmare. Total nightmare. You don’t want that to happen. And I’ve seen sites where that’s happened, getting technicians. Trained properly for the right material and doing that here up in Tennessee is, is the right approach. It’s risk reduction, which is what the industry is in right now.

Risk reduction.

Alfred Crabtree: Yeah. Yeah, we, we’ve beliefs. That’s a great way to put it. You know, if you hire somebody. We were talking earlier how there are like two models. One is like the New York Yankees, where you’re going to be buying all the expensive free agents. You can poaching people from other, you know, trying to get experienced talent.

You’re paying a premium for them, but you aren’t gonna know until halfway through that season how that person is performing. Yeah. You know, that is a lot of. That was, that is a lot of variability that you could control. Mm-hmm. And in a seasonal business, those weeks are really multiplied by two or three.

Right. In terms of like the impact on your revenue and your opportunity to make money. It’s risk reduction, like Alan was saying. Yeah. It’s

Allen Hall: all risk, right? Yeah. And the, [00:26:00] the way that the industry is moving and the pace at which is moving right now, risk reduction starts to move to the top five years ago.

We do a lot of risky things because we’re making money. Interest rates are low and, but today we cannot afford to do that. And if you watch the industry change right now, it is gonna be more focused than ever in having proper technicians on site that they complete the job that they were intended to do.

Precisely, accurately, and once, not twice. Once. Yeah. And that is gonna be the marker of the, whether this industry grows or not. Mm-hmm. And that’s why Blade Repair Academy is needed so much. Now, Alfred, how do you interface with the ISPs, OEMs, and the operators in terms of getting people out here? How do they, how do they push that button and say, Alfred, I’m gonna send you 40 technicians next week.

How does that, how does that go? I don’t quite have that down

Alfred Crabtree: yet. But, uh, you know, it, we talked earlier, it’s a small world. You know, blade repair is small. There [00:27:00] we mentioned if you, there’s a hundred people in the industry you need to know and then you’ve covered it. Um, our, I think we’ve been, we’ve been kind of riding this new wave of like, oh, who’s this new kid on the block?

And, and we can kind of be quiet and still are mysterious. And I pop up at a conference and host a round table or whatever. Uh, so far. It’s mainly been our personal network, which is large enough in this gig to, to get people in. ISPs are much more likely to do it small is ISPs are much more likely to do it.

Owner operators, they’re trying to build their training centers. They have a little different, that’s a different model though. It’s a different model. Um, they’re, they’re tougher to get. So primarily it’s been ISPs. We have definitely a, a, a curriculum for new hires, right? We call it support, but we’re [00:28:00] reluctant to go sell that to the street or to the public.

Like, Hey, enter the industry here, because we don’t quite yet have that, you know, guarantee that people will recognize our certificate and. Use it to hire people. I don’t quite have that system in place. However, I have so much interest from the Department of Labor to support us in creating an occupation.

They want us to build apprenticeship programs. We need corporate sponsor, we need a big employer or to to buy in, and then we can create an apprenticeship program. Then we can find public money for people to get some support to get into a new, a new industry. So, well, they

Allen Hall: need to come out here. They need to come out to Dunlap.

And visit the facilities, talk with you, understand what the philosophy is, see it up close. There’s a lot of them have been to other places. Sure. And see what the differences are here. And, and that’s gonna be the decision maker. They’re gonna see what the product walking out the door is and [00:29:00] go into the classroom and, and get the grinder, right?

Yes. Get, get your hands dirty a little bit. Yeah. And realize, yes, this is what I was looking for to begin with. I just couldn’t find it. And I found it here in Tennessee.

Alfred Crabtree: Yeah, I, I think you’re right. And, and we, we are slowly, you know, bringing people in that we know, like the reason why y’all are here and some other folks have visited us this week is because o and m was in Nashville.

And I was like, come on, come on. We’re only two hours away. We’ll buy you lunch. Come on. Pretty place. Yeah. You have to see this place to understand it because we are sort of, you know, outsiders, right? I mean, we’re, we’re from the, the industry, but we’re not. We’re not a spinoff of any company. We’re not a division of an ISP.

We’re totally organic and unique in a, in a part of the world that doesn’t have any wind. So, yeah. Uh, but once you get here, you get it. The economics make sense. You know, we couldn’t do what we’ve done anywhere else as cheaply as we’ve done, which means we feel like we’re super value rich for what you’re paying and for the amount of time that you’re spending [00:30:00] here.

Allen Hall: Oh, 100%. Uh. Let’s give the ISPs, the OEMs and the operators, uh, where to go. What’s the website? Where can they find you on LinkedIn?

Alfred Crabtree: We’re at blade repair academy.com. Uh, we’re located in Dunlap, Tennessee. We’re on Blade Repair Academy at LinkedIn. I’m Alfred Crabtree. You can find me there. Uh.

Allen Hall: Yeah, that’s where you need to go because that’s how the process starts.

If you want to have high level technicians that really know how to work on composites and are working with real materials on simulated, but. Pretty realistic damage. Yeah. Weirdly realistic. Yeah. Secret sauce. And to get some sort of validation and to kind of get graded. Mm-hmm. And so you have a, a, a sense of how they’re doing.

You’re going to have to go to Blade Repair Academy. You need to get out to Tennessee and you better check it out because I, Alfred, I gotta be honest, this place is gonna get crazy busy [00:31:00] and I’m gonna have. ISPs calling me saying, can you get a hold of Alfred and get me inside? Can you get me in? No, I can’t because it’s Alfred’s deal and Alfred’s gonna run this thing.

We’re very approachable and, but very approachable. Keep calling, he’ll answer and take care of you, but it’s gonna get busy because the philosophy here is the right one. Thanks. So congratulations for putting this together and thank you for the invite. Uh, it is been a pleasure to see it. It’s uh, it, it’s great to know that you are around and you’re helping the industry.

Alfred Crabtree: Thank you. We appreciate it and you guys are a great clarion for the industry. A great voice. So, uh, those words, uh, right in the fields. And I wanna thank Cheryl too for coming out. I haven’t seen her for a while. It’s funny ’cause today I, on my phone, you know, five years ago today, she and I were here before this business existed as rope partner employees working on r and d week doing infusions.

So, uh,

Sheryl Weinstein: the space has transformed. It’s amazing. Yeah. You guys have done a, a [00:32:00] really great job. Like I, yeah, I think you’re definitely pushing the industry into a, like a new realm. Bringing something that, that it really needs, you know, that we don’t have at the moment or that we didn’t have.

Alfred Crabtree: Yeah, well hopefully, uh, it improves everybody’s quality of product and the bottom line.

’cause uh, you know, that’s what we’ll do. We’ll affect your bottom line for sure.

Allen Hall: So Sheryl and Alfred, thank you so much for being on the podcast. Thanks guys. Right,

Sheryl Weinstein: thank you.

https://weatherguardwind.com/blade-repair-academy-training/

Renewable Energy

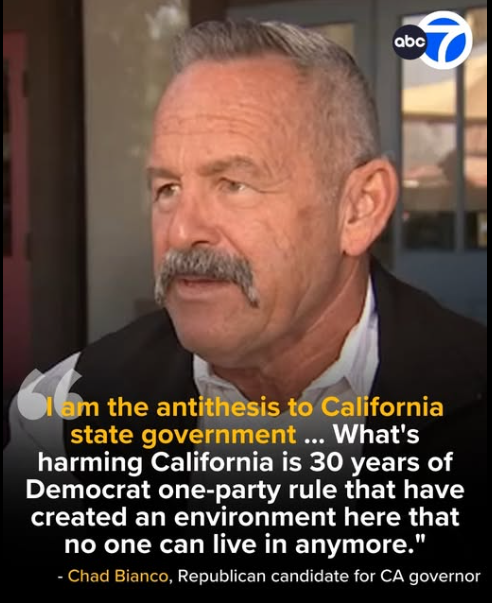

California’s Next Governor?

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

Yes, we have traffic, which we hate. But that’s because everybody and his dog wants to be here for our economic opportunities and our natural beauty.

In general, we reject racism, ignorance, corruption, and environmental destruction.

Renewable Energy

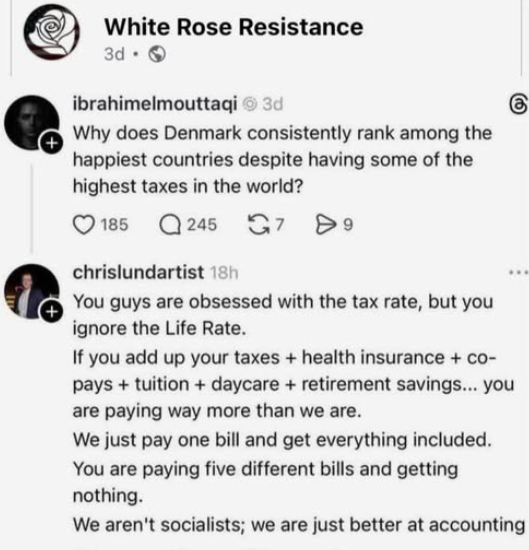

Understanding Social Democracy

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

They claim that the attraction is that they aren’t forced to live among uneducated slobs where people are dying of treatable diseases with masses of impoverished people living on the streets.

Isn’t there something to be said for that?

Renewable Energy

What Kids Need from Their Parents

Well, here’s a controversial statement.

Well, here’s a controversial statement.

Apparently, there are people who believe kids should be raised by dishonest imbeciles.

https://www.2greenenergy.com/2026/03/05/what-kids-need-from-their-parents/

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits