Weather Guard Lightning Tech

Monitoring Solutions for Aging Wind Turbines: eologix-Ping

Allen Hall and Joel Saxum interview Matthew Stead, co-founder of eologix-Ping, about the company’s growth, industry challenges, and their innovative sensing solutions for aging wind fleets. They discuss the benefits of eologix-Ping’s acoustic sensing, lightning detection, and blade monitoring technologies.

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Allen Hall: Welcome to the special edition of the Uptime Wind Energy Podcast. I’m your host, Allen Hall, along with co host Joel Saxun. We are in Minneapolis for the 2024 American Clean Power with the co founder of eologix-Ping, Matthew Stead.

Matthew Stead: Thank you, Allen.

Allen Hall: Matthew, welcome back.

Matthew Stead: Thank you. It’s great to be here. I actually was here with you a year ago.

Allen Hall: Oh, that’s right. In New Orleans. Yeah. So it has been a year since the merger of eologix and Ping. So a lot has happened over that time year’s time span?

Matthew Stead: Absolutely.

Allen Hall: Uh, we should touch upon that. I want, first want to get your opinion of what this convention has been relative to New Orleans last year, what your thoughts were, what the interfaces have been with your customers.

What’d you think?

Matthew Stead: Yeah, I think industry’s growing, fleets getting older, design issues, Every month, every six months, every twelve months, there’s more and more challenges we’re seeing, and I think that was reflected in the discussions we had here.

Joel Saxum: I think you’re getting that, it’s just being communicated, right?

Yeah. Hey, we have this problem, what can you do to fix it? I sat with someone last night at dinner and they literally just said I’ve got this. I want to do this. I want to do that. I want to do that. Who can do that? I said nobody can do all three, but this company can do this and this. I said, Pingmealogic can monitor for this and we can, you can do this for this.

And there’s some gearbox stuff for that. So people are looking for solutions for their plaguing problems. And I think that is exactly what you said as the fleet ages, right? It was before everybody was just like trying to catch up. And now you’re getting engineers into places. We do talk to a lot of people that are hiring engineers.

Hey, this person’s brand new to our team. Whether it’s from the insurance side, asset owner side, even ISPs. I talked to an ISP. Hey, we got a great new blade engineer to help bolster our ability to repair blades. It’s oh, that’s fantastic for you guys as well. So more engineering help. And that’s just giving more bandwidth to the basically the stakeholders in industry to solve these problems.

Matthew Stead: Yeah. Yeah. Yeah. And we’re all here to help.

Joel Saxum: Yeah. For sure. This is the place for it.

Allen Hall: We have seen a lot of engineers this week with specific problems. Mostly blade problems, occasionally bearing problems, even though it depends on the platform. There’s some platform with a lot of bearing issues at the moment.

And we have seen a narrowing down of the possible solution companies. And that’s what I noticed this week. The number of drone companies has really diminished robot companies way down. It’s around pretty much left, right? Because there’s so dominant in that market space. And then when it comes to acoustic sensing, remote sensing, continuous monitoring, that’s the logic’s ping at the minute because of the, Really gets down to cost, right?

And what the product can do. So you packed a huge amount of information in this little tiny package that doesn’t require any wiring. And that just has opened up the opportunities for eologix-Ping. I think it, there’s, everybody was talking to, what can we do? And when they come to our booth, we say, eologix-Ping has the most cost efficient, readily adaptable, on the go product.

That’s awesome. Just stick it on and go. And which is a game changer, right? So the continuous monitoring systems that we were, we’re seeing a year ago that were these big monster boxes with the wires everywhere.

Joel Saxum: Yeah.

Allen Hall: They’re essentially gone.

Joel Saxum: They’re for engineering projects. They are. And you’re not going to roll, you’re not going to roll that out.

Fleet wide recalls. Yeah. Yeah. Cause at the end of the day, this is what we need to be able to do. We need to enable the guys in the O and M building to know what they need to do and prioritize. So like the lightning strike. I don’t need to know every bit of metadata about that. I need to know which turbine got hit.

Matthew Stead: Did I get hit? Which one?

Joel Saxum: Go look at it. Yeah. Or is there an issue here? Because at the end of the day, every CMS system tells you at one point in time, go look at the turbine. So if you can do that in the most cost efficient way, that’s the answer.

Allen Hall: Even the number of engineers that were here, when we talked to them, and how many assets do you have, how many turbines do you have?

We have thousands. How many blade engines do you have? Two!

Matthew Stead: Not enough.

Allen Hall: There is no way you’re going to be able to monitor that many turbines without having a tool. Yeah. There’s no way. Too much data. Too much data, not enough simplicity to it, and you can’t quickscan, which is the problem I see. That eologix-Ping is fixed, is the quickscan,

Matthew Stead: What’s the hot list?

What’s the top 10%? What’s the top 20%?

Allen Hall: Yeah, you got to get to that list really quickly, every morning.

Joel Saxum: And you can take a look. And you can scale and install on a wind farm in a day. The way I look at that is I could, if I got my shipment of ping sensors, right? Of the acoustic ones, and I had, here, boys, put this in the back of your truck, and we’ll put this on every tower we have out there.

Okay, they’re done at the end of the day. And all of those turbines are now monitored. Whereas if you have to install, Get up in the blades and this and that. It said the ability to scale up the monitoring effort is not there.

Matthew Stead: Yeah. And that’s where we started. So I think when I founded the business, I didn’t try and design a product and then try and sell it.

I spoke to the customers, what can you afford, what are your challenges, what do you need? And then we designed a product to suit that. And that’s the way it should be, right? It should be. That’s a huge problem.

Joel Saxum: Okay, so this is a conversation I have regularly. I’m a bit plugged in some of the the VC world and the tech world in Houston.

And there’s people that go to these places, Greentown Labs, the ION, that walk in there and just say Hey, wait a minute. Do you have basically a development partner? Have you talked with some, instead of breezing by a bar room conversation of primary market research, are you actually engaged with these clients and solving the specific problems they have?

Otherwise you’re making a solution for a problem that doesn’t exist. It doesn’t work. Yeah. It doesn’t work that way.

Matthew Stead: Yeah. So I’m really pleased that you’re relaying what we set out to do. Yes.

Joel Saxum: Yes.

Matthew Stead: Yes. It’s been worth the effort. It’s been worth the effort.

Allen Hall: I took that tour along with Joel. If you’ve been listening to the podcast very long over the last month or so, you’ve heard about our travel log of going through West Texas and up through Oklahoma and looking at all kinds of turbines.

There are problems everywhere. Cranes are out right now fixing blades. There’s a lot of pitch bearing issues. There’s a lot of structural issues inside. And then when we had stopped to talk to the OEM supervisors and managers of those sites, they’re saying, Hey, We have so many problems, we can’t monitor it.

And some of them we just need to monitor. We just going to have to put a monitor on and they’re looking at solutions or trying to figure out how to monitor a hundred turbines that have some sort of internal blade issue that they know of. How are they going to do that? Either you’re going to send a technician around to do that every couple of weeks, which just kills your technician.

They’re already killed. Yeah. Yeah. They’re already stressed. You’re gonna have to bring in some outside crew to go do it. Super expensive. Yeah. Or you’re gonna put some sort of continuous monitoring system in. Now, when we stopped at one of those offices, we said the internal blade monitor From eLogic’s ping is the quick solution because it does so much and everybody is just mind blown.

There’s no wiring. Do you want to describe how that system works?

Matthew Stead: Yeah, so there’s two parts. We have the listening sensor, which has got a lovely windshield, which looks beautifully black. So that’s intelligent listening sensor and now we have the power and comms module and power and comms module power.

but also the lightning detection sensor. So putting them both together. So we’ve got the intelligent listening sensor and the power and comms module, and we just plugged them together. It turns it on and slap it on with the magnets onto the tower.

Allen Hall: And so that’s the internal internally inside the blade, which is where the technicians were going with me that are saying, okay.

Yeah, but I can’t really see in this dark blade. How am I going to monitor it? I’ve seen other systems where I got to put strain gauges on and all this stuff. I got wiring everywhere. And that is, it’s too much. It’s going to take me 10 hours and stop for blade. That’s crazy. The in blade solution just sticks to the closeout panel, right?

Matthew Stead: For the logic spring version of it. So the in, in blade one, we’ve got two parts to it. Once again, the listening sensor, and then we’ve got a kinetic power supply. , that’s it. You plug them together, turns on. It’s got all its comms, that’s it. And it’s all on the closeout panel.

Allen Hall: And that doesn’t even talk to the SCADA system in the tree?

Matthew Stead: No, completely. No it’s a completely separate, completely. Each blade is separately talking through cellular comms back to the cloud. So even each blade doesn’t talk to each other. ’cause there’s no wires between each plate. So each system is one per plate.

Joel Saxum: So you’re solving the cyber security issues there too.

Yeah, because there is none.

There’s no connection

Matthew Stead: to the tower. Yeah. Yeah. Yeah. Yeah. Sorry it bolts to the close up yeah.

Allen Hall: But we’re talking about a couple of bolts a close up panel versus all kinds of wiring.

Matthew Stead: Yeah. Yeah. There’s no way No power coming from the hub, you don’t have to get past the slip ring get past the pitch bearing None of that stuff.

Allen Hall: Yeah, I think that’s gonna be the solution We see across the middle of the United States this summer And as everybody gets used to the fact of we need to go monitor, we need to be spending a little bit of money to go do it. Not a lot of money, but a little bit of money to go do this. The eLogic’s ping is the quick, simple way to get there.

And let’s go outside of the internal inspection, where we’re getting the outside of the blade, things we can visually see. We’ve been using, Weather Guard has been using the eologix-Ping lightning detection system with some of our customers to detect lightning strikes. So they have StrikeTape product on.

Yeah. We want to show them they’re taking strikes and just record and monitor it. Yeah, no damage. We want to show there’s no damage and the key to that system, which is working so well in customer’s love, is the same thing with the internal sensor is, it’s so easy to see it. Yeah.

Yeah. It doesn’t take really any training at all. You just open your laptop, look at the screen, it’ll tell you if it took a strike. It actually sends you an email. Yeah. It says, hey, you’ve been struck. Oh. And the added feature now, the new feature on the lightning side is what?

Matthew Stead: So now we correlate when there’s a lightning event determined from our sensor.

We know the tower’s been struck. Now we correlate Xweatherr data. So Xweather is recording the polarity. Cloud to ground, and so I’ve got killer amps, so now we can correlate a real event with the Xweather data.

Allen Hall: And we had a real life situation with that system and some of these horrible Oklahoma storms.

They had a recent storm just west of Oklahoma City, and if everybody remembers back, there was tornadoes and all kinds of horrible things from that storm. One of the things that happened there also was they had Essentially, all the lightning strikes in that part of Oklahoma were positive lightning strikes.

Yeah. And they were huge.

Yeah. 100 kiloamps each. So the turbines with StrikeTape were hitting, getting hit with 140, 160 kiloamp strikes. Those are big strikes in the United States. And they were all positive. And positive strikes tend to be the ones that damage the blades. Yeah, absolutely.

Those are the ones that most likely damage the blades. The ping, you got to pick them up every time. Yep. Every time on top of it, it was picking up. We had some notifications of this turbine got struck, but this one also had a leader on, which was a couple hundred amps. So we picked up the really high one.

We picked up ones that were under 500 amps to a turbine. So it alerted us to that. Yeah. So now we have a better understanding of what has happened out in the real world, because what did the operator do? They sent technicians out. To the turbines that were struck.

Matthew Stead: Not doing a random inspection over a field.

Not knowing which ones to inspect, or which ones got hit.

Allen Hall: Some of these farms, as Joel knows, we drove around them, are 10, 20, 30, 40 miles across. It takes an hour to drive from one end to the other. Yeah.

Joel Saxum: You’ll burn up a technician real quick their whole day just looking at turbines. So if you have a hit list, say in the morning, hey, turbine 4, 7, 10, 12, and 6 got hit last night in that storm.

Yeah. Go look at them. Perfect. That’s easy.

Matthew Stead: Yep. Rather than spending the whole day driving around. Yeah, these guys are flat out. The industry is stretched for results. And

Allen Hall: They’re all fixing pitch bearings and main bearings, right?

Matthew Stead: So they don’t have time to be running around looking at blades.

They got other things to do. Making their life easy.

Allen Hall: Yeah.

Matthew Stead: Yeah.

Allen Hall: So the acoustic piece, which is the brain, the heart of the eologix-Ping system, that has evolved over time. So the first generation of the acoustic. It is from the software side. He’s gotten a lot smarter since absolutely scary, smart.

Yeah. So inside that little acoustic sensor, if you see it, you’ll, if you look at the base of a tower that has a pink sensor on it, it’s pretty easy to pick out inside that black death star looking piece, there’s microphones in there. There is what we’ll see. Exactly. There’s okay. There’s six microphones in there and there’s a microprocessor.

Exactly. And it’s about the size of a deck of cards. Yeah. Roughly. So in there is a lot of processing power though. Yeah. So the understanding of what’s happening with the blade isn’t happening remotely. It’s actually happening on the tower.

Matthew Stead: Yeah.

Allen Hall: And that software has evolved because you’ve been on so many turbines all over the world.

You now have to understand like how a Siemens turbine performs and what noise it makes and what it means. You have understanding what a GE or an LM blade makes versus a TPI blade makes. They all make slightly different noises with different problems. So if you buy that system now, you have all that history already built into the acoustic sensor.

Matthew Stead: Yeah. We’re approaching 1400 towers now under monitoring. Wow. Yeah. Okay. Yeah. I think a year ago we were probably about 500, 600. Okay. Yeah. So starting to, yeah. You see that ramp up happening. I’m pleased to take orders of another thousand today.

Joel Saxum: Yeah. P. O. is booth 434.

Matthew Stead: We can deliver now, so that’s probably the key thing as well.

Joel Saxum: Yeah.

Allen Hall: And the one of the issues that everybody thinks about is okay, we’re in remote Texas. How does this thing connect up? Like, how does it work? If it’s not hooked up to my SCADA system, do I have to have Ethernet on site? What is, how does that actually work? How is it transmitting data and where does that data go?

Matthew Stead: Yeah, so we’re using cellular comms. And we’re using like a machine to machine comms, which is part of the 4G family. It’s 4G, but it’s called LTE M which is low power, long range. Actually in the U. S. We’ve only ever had one site where we really had challenges on comms. And that one site was near a military facility.

So maybe there was some other, that makes sense.

Allen Hall: So as long as you, your cell phone works, your technician, cell phone works, your Samsung works.

Matthew Stead: Our system works even if they don’t, because we’ve got longer range. Yeah, exactly. Cause we’re transmitting hundreds of bytes not voice. So probably.

Anywhere in the states, the continental United States. Apart from near that military facility. Yeah, no, we’re good. This year we should also be coming out with a satellite version. So if there are any black spots, you’ll have it. So

Allen Hall: is that a start? Offshore, yeah. Offshore, yeah, I wanted to talk to offshore.

But the communication bit, Starlink and those kinds of systems, that’s the next gen. Yeah. Is that already in process? Yeah, that’s this year.

Matthew Stead: That’s this year? Yeah. Okay. Yeah. So we’ll have more of a hub and spoke approach. So you’ll have a central hub talking to each of our devices and then that will then start linking up to Elon or whatever.

Yeah. Okay. Okay. Hopefully not to him personally, but sometimes he’s listening. He might be listening.

Allen Hall: The offshore piece also because the onshore has been so successful. Obviously offshore’s the next gen and that’s where a lot more risk is in terms of new turbines and new environments that don’t have a lot of previous history.

Joel Saxum: It was, it’s a just Hey, east coast US offshore, it’s going to be a different animal.

Allen Hall: Yeah, we’re seeing everybody start to be worried about it. We talked to an operator, a really big operator that was concerned about that, particularly offshore, who also was using your system. over in Europe to trial it and what they told us and you weren’t in the room when they told us is Hey, the ping works.

Everything else we tried doesn’t work. It gives us erroneous data, a lot of false positives. We’re sending technicians out to check things that don’t exist. When we have a ping alert, it’s real and it’s actionable. So is that sort of development process that’s happened offshore in Europe? Is it starting to move towards the United States?

Matthew Stead: Yeah, absolutely. We also believe in like triangulation, like getting multiple sources of data so that, no false alarms. That’s really our aim.

Yeah. Yeah. We’re also now measuring on the blade with the eologix OnBlade, former eologix OnBlade sensor. Now we know exactly how the blade is moving or we, through, censoring.

Allen Hall: And let’s talk through that because Some of these new blades have weird dynamics. GE went through that effort on one of their blades that there were some deflection issues and they ended up putting some counterweights in basically to, to solve it. Yeah. But we’re seeing because blades get longer and the structure’s a little bit different and the environment as Joel pointed out is unique at times that you need to have a little bit of understanding of how the blades are actually moving in wind, no wind situations because changes there in The way the blade undulates Yeah.

Indicate problems. And there’s really no way to do that right now without putting a bunch of strain, eight time sensor on it. Yeah. So how does that system work then? If I wanna understand how my blade is moving, particularly, they got a new farm and I’m thinking like Sunz, right? So Sunz, there’s a thousand turbines out there.

Crazy. And all those turbines are new.

Joel Saxum: The blades are new. Everything about ’em new and the, those turbines don’t even have type certificates yet. No. As we learned,

Allen Hall: it would be a smart move. That’s a pattern energy project, right? So it would be a smart move if I’m patterned, not that I’m patterned, not that they would hire me to do this, but in my head, I’m thinking I just need a monitor to see how things move for a while.

Yeah. Then I’ll understand what good looks like versus problem. It does make sense, you think, to put some of those eologix-Ping sensors on Blade, especially when they’re on the ground. Yeah, exactly.

Matthew Stead: That’s the best time to do it.

Allen Hall: Just instrument it, put them up, start getting some data. The engineers at Pattern, the Blade engineers, are superb, right?

But they are overworked and they have a lot on their plate already. And we’re going to build the world’s largest wind farm, pretty much. Yeah. So the workload just got even a little harder. Is that the right approach then from a continuous monitoring standpoint?

Matthew Stead: Yeah, that’s the direction we’re going.

We’ve got one product out there at the moment, which talks about pitch misalignment continuously where they need to. Okay. But our sensors are able to go, up until about 20 percent mark, 80 percent from the root. And we can measure the vibration. So we know what the blade’s doing, how it’s moving.

Joel Saxum: Yeah, this is the next step for us. If I was someone who had the new two piece plates. I would put sensors, I’d put them on either side of the two piece, the joint.

Matthew Stead: No comment.

Allen Hall: I’d want to know. I think Joel, you’re right, is that it’s new technology. It has a little bit of history. That history has shown some weakness in the design. And I know there’s been a lot of effort to resolve that. But if I’m buying those blades now. Safeguard yourself. You want to safeguard myself. It’s a lot cheaper to detect it early than to detect it late.

Joel Saxum: Orders of magnitude. Yeah, absolutely. Especially, you want to make sure if there’s something developing, you catch it before you’re into warranty period.

Allen Hall: Oh, gosh, yeah. Once the warranty ends, the fight escalates.

Joel Saxum: Yeah.

Allen Hall: Yeah, the lawyers become involved and it gets ugly. The last piece I want to talk about is the icing sensor.

eologix has an on blade icing sensor. The Ping unit, the acoustic sensor, can also detect ice. It seems like there’s a lot of operators in the United States, Texas, all the way up in Minnesota, Canada that have icing issues and they talk about them on a downtime. And we had talked to our care about that too.

Joel Saxum: Yep yep. Yeah, I actually spoke with quite a few people here about icing this week. And I think it may have something to do with us being in Minneapolis. Yep. Ha. It’s beautiful outside of the mountains. Yeah, it’s fantastic. It was a beautiful week. But the people that are here from a stakeholder standpoint, there are, National Grid Renewables is here in town.

And Xcel Energy is headquarters, is down the street. And so the people that operate in these cold climates are here at this show. So I’ve heard more talk about icing. Here than I have, than you do normally.

Matthew Stead: Yeah.

I think, For us, ice is the core of, where we started with the eologix side. Yep.

Absolutely the core of where we started, but the future is ice and beyond, the damage and the like. That’s really where we’re going, but it’s where we started, so we, we’re monitoring, we’re stopping, we’re restarting where it’s safe. Yeah, and we’ve got, a whole fleet of problems, a fleet of sensors there.

Joel Saxum: So you’re, but the fleet of sensors, whether it’s the acoustic side, the lightning detection, icing detection, vibration, displacement, like anything that’s affecting a blade from an environmental standpoint, basically you guys, you’re picking up. Yeah. Yeah, that’s why we want to offer everything. It’s like holistic environmental monitoring for intern.

Yeah.

Allen Hall: And the way that the eologix-Ping model is set up right now, the economic model, is you choose the things that you need.

Matthew Stead: Yeah. You turn on the pieces you need. Don’t need it, don’t buy it.

Allen Hall: If you’re in Southern California, it’s not going to snow.

Matthew Stead: Yeah. Probably don’t need the icing. Not in Australia.

Allen Hall: Or Australia.

Matthew Stead: I always think it’s a bit funny, I’m trying to sell, or work with customers around icing, and yeah, there’s no icing in Australia.

Allen Hall: No. The Rosemary has been skiing there. Yeah, she tells us there’s snow.

Matthew Stead: There is snow. There’s just no turbines there.

Allen Hall: Yeah, that’s right, yes. So this has been great to have you visit the United States again, Matthew.

It’s great to be here. And spend some time at American Clean Power. And it’s been a tremendous week, I think, for everybody who has participated.

Joel Saxum: And people that went to the Twins game last night and watched the Twins win.

Matthew Stead: And our team won.

Joel Saxum: Yeah.

Matthew Stead: Yeah. Yeah. Yeah. Yeah.

Allen Hall: Thank you. Yeah. So Matthew, thanks for having on the podcast.

How do people reach out and connect with eeologix-Ping to get some continuous monitoring on their turbines?

Matthew Stead: Yeah, just eologix-ping.com. Yeah. Okay. They’ll find the right people. And or me personally, if you wish, matthew.stead@eologix.com.

Okay. Wonderful. Cool. There we go. Matthew, thank you so much for being on the podcast.

Thanks guys.

https://weatherguardwind.com/monitoring-solutions-turbines-eologix-ping/

Renewable Energy

California’s Next Governor?

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

Yes, we have traffic, which we hate. But that’s because everybody and his dog wants to be here for our economic opportunities and our natural beauty.

In general, we reject racism, ignorance, corruption, and environmental destruction.

Renewable Energy

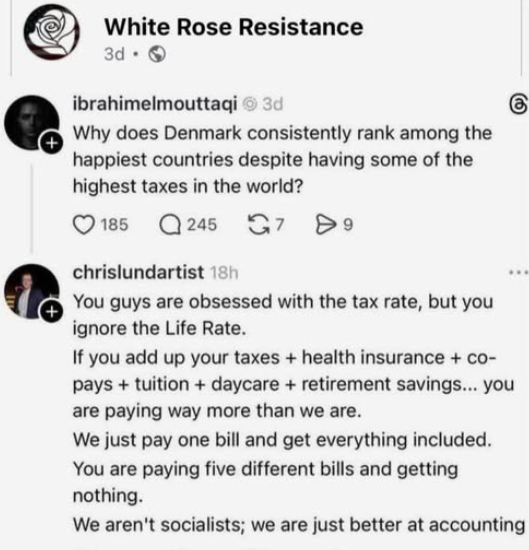

Understanding Social Democracy

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

They claim that the attraction is that they aren’t forced to live among uneducated slobs where people are dying of treatable diseases with masses of impoverished people living on the streets.

Isn’t there something to be said for that?

Renewable Energy

What Kids Need from Their Parents

Well, here’s a controversial statement.

Well, here’s a controversial statement.

Apparently, there are people who believe kids should be raised by dishonest imbeciles.

https://www.2greenenergy.com/2026/03/05/what-kids-need-from-their-parents/

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits