GE Vernova Restructures Offshore Wind Division

Allen, Joel, and Phil dissect GE Vernova’s restructuring of its offshore wind operations, potentially cutting 900 jobs globally. What will be the implications for the US and international wind energy markets? They also share key insights from the Sandia Blades Workshop, emphasizing the importance of prescriptive operations and digitizing tribal knowledge. Enter to win a bunch of Yeti and StrikeTape swag at https://weatherguardwind.com/yeti!

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Allen Hall: Hello everyone. Joel and I have been traveling across America talking with GE2X wind farm operators about how strike tape can protect their blades against lightning damage. If you work on a GE2X site, you need to visit our new website. weatherguardwind.com/yeti. We’ll show you how your turbines can be protected against lightning with Strike Tape, and you can also register to win a nice Yeti Roadie 48 cooler, four Yeti mugs, and some Strike Tape swag.

Just visit weatherguardwind.com/yeti. Phil, have you been to the National Toy Hall of Fame in Rochester, New York?

Philip Totaro: I have not.

Allen Hall: Oh my gosh, you’re missing out because they have the finalists, the twelfth finalists for induction into the National Toy Hall of Fame this year. And they include, are you ready?

Drum roll please. Balloons, Pokemon cards, your own adventure books, which is a particular kind of interesting book. Hess toy trucks, which we see at Christmas time here in the United States. My Little Pony, which should have been an entrance a long time ago, honestly. How is that not already in there?

Exactly my point. Remote control vehicles, stick horses, trampolines, and probably one of Joel’s favorite, Transformers. I’m a Transformers fan.

Hang on, let’s go back to stick horses for a second, because again, how long has this museum been, or Hall of Fame been in business? I mean, are they, they’re digging up some pretty legacy toy technology there.

Stick horses are back. Have you seen those competitions of, where people are riding the stick horses over a competitive course where they’re hopping over things and running around?

Philip Totaro: There are some people that think that the United States Is not going in the right direction. I think these people are probably steering us in exactly where we don’t need to be.

Joel Saxum: Allen, when you said that the Toy Hall of Fame, I looked over at my bookshelf and I have to, I went and grabbed this toy, because to me, this is American Toy Hall of Fame material. This was, this toy was my dad’s when he was a kid. And this is the original Mound, Minnesota built Tonka trucks.

Allen Hall: I think we all need to take a moment and observe and salute the old Tonka truck.

I

Philip Totaro: will salute that.

Joel Saxum: Working tailgate, I’m telling you, that’s it right there.

Philip Totaro: That’s a toy.

Joel Saxum: It even says USA on the tires.

Allen Hall: Made out of American steel and the edges are sharp like they should be.

I’m Allen Hall and here are this week’s top stories. In a significant corporate development, the Spanish government has authorized BlackRock’s stake in Natergy. This follows BlackRock’s acquisition of GIP, which owns 20. 6 percent of the Spanish energy company. The approval comes with conditions, including support for energy transition projects and maintaining Natergy’s headquarters in Spain.

This move positions BlackRock as a major player in Spain’s energy sector. Denmark has inaugurated two new offshore wind farms. Vesterhavnord and Vesterhavnsyd, developed by Vattenfall, these farms feature 41 wind turbines with a combined capacity of 344 megawatts. Located between 5 and 10 kilometers from the Danish west coast, they will generate 1.

5 terawatt hours of electricity annually, enough to power 350, 000 households. This addition brings Vattenfall’s total offshore wind capacity in Denmark to 1. 5 gigawatts. Marking a substantial increase in the country’s renewable energy output and a boost for the North American wind industry. The Canadian port of Argentina has secured a contract to handle wind turbine blades for U.

S. East Coast offshore wind farms. The port will receive and store 220 wind turbine blades starting this fall and continuing into 2025. This agreement with ScanGlobal Logistics positions Argentina as a key player in the offshore wind supply chain, building on its previous contract for monopile marshalling and strengthening the infrastructure for wind energy development in North America.

In Canada, Marmot Energy is restarting wind tower manufacturing activities in Quebec. A new wind project will add 100 jobs to the facility and install 56 Vestas turbines generating 350 megawatts of renewable energy. The 1 billion project is set to begin construction in 2025 with commissioning planned for next year.

Moving to Hawaii, AES Hawaii reports success with a new bat deterrent system at its Kahuku Wind Farm on Oahu. The project uses an ultrasonic mechanism on its turbines to keep bats away. Since operations began in December 2020, only one bat strike has been recorded. The project’s eight turbines, reaching 40 stories high, generate enough power for 16, 000 homes.

Breaking news. And in the UK, an investigation is underway following a collision between a service operation vessel and a wind turbine at Oersted’s Hornsea One wind farm. The incident involved a Wind of Hope vessel carrying 72 people. No injuries or pollution were reported, but damage was sustained to the vessel and to the turbine base.

That’s this week’s top news stories. After the break, I’ll be joined by my co host, CEO and founder of IntelStor, Phil Totaro, and the Chief Commercial Officer of WeatherGuard Lightning Tech, Joel Saxum. As wind energy professionals, staying informed is crucial, and let’s face it, difficult. That’s why the Uptime Podcast recommends PES Wind magazine.

PES Wind offers a diverse range of in depth articles and expert insights that dive into the most pressing issues facing our energy future. Whether you’re an industry veteran or new to wind, PES Wind has the high quality content you need. Don’t miss out. Visit PESWind. com today. In this quarter’s PES Wind Magazine, there’s a lot of good articles and you can check them all out at PESWind.

com. And if you’re over in Hamburg, And looking at the exhibitions all over the floors there, a big part of that exhibition is about offshore wind. And one of the issues with offshore wind is the tooling that has to live out there. And an article from Hamatro, who makes hydraulic tooling that’s made for offshore they have a really interesting description of what they do and all the processes and application tools that they have to have hydraulic tools in an offshore environment, because as Joel knows, anytime you get saltwater and moving hydraulics, it is a disaster.

Joel Saxum: Corrosion

Allen Hall: central.

Joel Saxum: Yeah. One of the things to think about or to understand here is that when you get in an offshore operating environment, not only like Allen says is the salt water, the wave heights, the bad, moving things around with lifts and all this stuff. It’s a very difficult environment to operate in, but almost everything.

And this is where it makes it difficult. Almost every tool you use offshore for construction or decommissioning for that matter is custom built. And you’re dealing with really large things. It’s not like you go to snap on and say, Hey, give me this tool or Milwaukee tool. Hey, give me this thing.

And we’ll, and yeah, we may, we make a hundred thousand of these and we’ll sell you one, every single piece of equipment that goes offshore in these large applications is custom built for the application. So whether it’s decommissioning or construction. You have to make it usually these things are designed in like a front end study.

So someone like home mantra will get involved with a wind farm that’s being built years. Sometimes ahead of when they actually think it’s out there, because they need to develop the tool. They need to build the tool. They need to test the tool. They need to get it ready to roll before that thing is.

Gets out moving that construction project because you don’t get to just run to Home Depot and buy a new tool. Everything has to be custom built. And the other side of this thing is what whole mottro does is their hydraulic specialists. In the offshore world, hydraulics is the only thing that you really can, Make the kind of power, create the kind of power that you need to cut, to move, to, straighten out a monopile or to crush something down or connect something because electric pumps or just don’t do it.

A lot of the times in a subsea environment, you’re having a, what’s called a work class ROV, the remotely operated vehicle, becomes the hands, the eyes, the ears, the everything in that subsea realm. And a work class ROV will usually be like 150 horsepower is what they call it, but that 150 horsepower Is driving hydraulic pumps.

And if you’ve ever seen like a house lifting jack or a car jack or something, that’s all hydraulics. And there’s the only way to control that kind of power. But these guys are a specialist, this Homatro company that’s in PS when this magazine this month, they’re specialists in creating these special, these.

Specific tools that are needed for specific actions on an offshore wind farm for from construction all the way through decommissioning. Yeah. 1 of the things that whole matro focuses on is in house R and D and innovation and that can go really far into making sure as a client of someone like this. So I’ve seen places where some of the engineering gets farmed out here.

Some of the engineering gets farmed out there. A piece gets built here. You put things together here and the companies that usually provide tools that just simply work and work day in and day out are the ones that have controlled the design and build and deployment process from start to finish. And that’s what Homatro does.

Bringing quality to the to the offshore wind market.

Allen Hall: So check out the latest PES wind magazine at PESwind. com. GE Vernova has announced a major restructuring of its offshore wind operations and the company plans to downsize its global workforce in the offshore sector, potentially affecting around 900 jobs out of an estimated 1700 employees involved in offshore.

In France, about 360 positions will be cut in two facilities that represents about 60 percent of the employees between those two facilities, somewhere 50 60%. The restructuring as it’s being explained today is in response to challenges in the offshore wind sector, obviously inflation, supply chain disruptions, and some project delays.

And with the offshore wind division having financial difficulties and expected to lose about 300 million dollars in the third quarter, the Vernova heads of the company are thinking about, Really reducing the offshore business greatly and Phil, I think this has a couple of implications Globally particularly in the US right now where GE has been selected to do a couple of offshore projects and then What’s happening internationally if for Nova reduces its offshore Manufacturing capability are they going to aggressively go after business or are they going to sit on the sidelines for a while?

Philip Totaro: No, I Allen I think it Indicates they’re potentially going to sit on the sidelines and they may still maintain, a sales force in, emerging markets that they want to be in, like Australia, for instance or even South Korea but operationally, I question how they’re going to be able to execute without getting the order book built up in those markets in the first place.

The reason why they’re largely targeting Europe and potentially the U. S. is there have been some, in the U. S. there have been some project cancellations where, G. E. turbines were going to be utilized. There are also projects where leading light that has delayed the project as a result of GE indicating that they’re not going to develop the 18 megawatt variant of the turbine, which to be blunt, I find a little curious because he, there’s not that much difference.

On LCOE between a 15 and a half megawatt turbine. Yeah, you’re gonna save yourself some capex on foundations, but it’s not actually that great of a gulf. So I’m getting the sense that maybe there’s something else going on there. But for GE’s benefit, they just haven’t been getting the orders, particularly in Europe.

So they’re getting through Dogger Bank. They’re getting through some of the, big and small projects that they have lined up in France. But after that, I am not seeing them getting significant orders in, for instance, Holland or Germany, where, and even some of the emerging projects in Sweden and Norway and elsewhere in Denmark, they want to be able to play in those markets, but they’ve been unsuccessful due to competition from Siemens Gomesa and or Festus.

So the industry keeps saying they want, multiple supply chain options, but if they’re not going to give GE the order book, then this is the inevitable consequence of that.

Joel Saxum: Yeah. In this press release that we’re following along with here, one of the things they say is they are experiencing lower than expected volume.

And that’s a and that part of that is delays in known projects, but some of it is just, they’re not getting the new ones. And we’ve talked before about other brands and when things happen that are, in the recent news, right? Like we’ve seen Vineyard win. We’ve seen the Dogger Bank blade issues.

They also go on to say in this press release that the company will continue to allocate resources to support existing projects, including quality control issues affecting its plates. So there’s they know they have that issue. And what that points to me is wounded brand, which we’ve used that comment before, but it’s something to look at, right?

If you’re going to be developing a project right now, and you’re picking your turbines, and you’ve seen 3 blade failures on the Haliide platform offshore for GE Vernova. You’re going to get the hair on your back of your neck up a little bit about that. So that is something also that’s driving that lower than expected volume of order book.

So it’s a tough spot to be in. I know as GE Vernova, the spinoff last spring from aerospace and health, and what they’ve done as a GE as a whole. But now we’ve seen massive layoffs at the on the LM side of things, some plants closing, GE getting rid of a bunch of other engineers. So they continue to whittle down at the massive tree that was GE to get to something more profitable.

But as it sits right now, it’s tough to look forward in a crystal ball and see how, what’s going to happen in a few years or how they’re going to arrive at this profitability and then come out of it stronger.

Philip Totaro: GE Vernova was in a period where. They went through something similar with the onshore wind business as well, where they had supply chain pressures and other profitability pressures that caused them to really scale back the size of the business, the size of their product portfolio, et cetera.

I think with the lack of order book, it’s just again and an inevitable consequence of saying, all right, we’re going to focus more on profitability. And this is what that entails. We can’t employ, these 900 people globally, if we’re just not getting the order volumes, we anticipated part of that again is because of interest rates.

But I don’t it’s interesting because like in the past few days prior to this announcement, Wall Street was already, pumping up Vernova’s stock, and it’s almost like they had, some, maybe, knowledge that, that this sort of announcement was coming, because typically, Wall Street Actually likes layoffs because they think it leads to more profitability.

And so even as horrible as that sounds for the people, working in the factories that is the cold hard reality of, equity investors they like to see companies downsizing, if it means that they’re going to be more profitable and. That’s the direction that GE Vernova feels like they, they have to go at this point.

And, again, without the order book I can’t blame them. It’s basically a scenario where, again they’ll scale back up, either when interest rates come down more, and more capital starts flowing, But keep in mind as well, we can also pin this on, New York and New Jersey a little bit playing a lot of baseball with, project developers.

The factory commitments that GE had made a lot of the jobs that we’re talking about right here would have been either preserved or even increased had those factories moved forward. But project cancellations or delays in the U. S. has resulted in. A lot of this if you’re going to the voting booth in November, remember that when it comes time to tick the box for, the governors in the states of New Jersey and

Joel Saxum: New York.

I think the one thing that we need to make sure we focus on here as well as GE has stated for these projects that are under development. They’re going to have the resources that they need to fulfill the contractual obligations right there for the upcoming years. No problems with what’s going to happen to make sure that the things that they’ve got going right now are going to continue to they want to execute the projects in a timely manner, keeping safety and quality at the forefront.

This makes GE Varnova stronger. And

Allen Hall: the next couple of years.

Philip Totaro: It does, or it eliminates resources that they’re really going to need when the time comes to, execute on things it’s, you’re seeing this right now with some of these challenges that they do have with Vineyard Wind and Dogger Bank with the blades, because a lot of the engineers at LM that would be responsible for potentially designing and fixing some of these.

Again, whether they were operational issues or, manufacturing issues or what have you, you still need engineers to, to help you fix that you can’t lay everybody off and then just have salespeople say we’ll, still be able to maintain our contractual commitments.

You know the asset owners and operators and more importantly probably the insurance companies aren’t stupid So even though it looks good to investors you also have to balance that with actually being able to fill your contractual obligations

Joel Saxum: I think you’ll see that the same thing that you see in a lot of situations like this whether it’s wind or the Doesn’t matter aerospace sector or anything Is a lot of these people, as soon as that next project ramps back up, you’re going to see a bunch of contractors, quote, unquote, getting hired by GE, which is going to be the exact engineers that just laid off, just writing them contracts to come back and work temporarily.

Cause that’s the smarter way to do things right now.

Allen Hall: There’s a high demand for these skilled positions, engineering technicians, even people laying up blades. They’re hard to find. There’s a lot of opportunity out there. And if it’s not with GE Vernova today, it’s worth. One of the other manufacturers that will be going into offshore and I kind of wonder Phil if they intend to eventually sell off.

The factories that are in France and consolidate in Canada and in the U S

Philip Totaro: that’s complicated because they, going back about 10 years to when GE was merging with Alstom, there were a lot of promises made and the whole reason that the factories got built in St. Nazaire and Cherbourg and France.

Was because of the commitments that GE had to make to the French government not to lay people off in the first place. So we’re getting 10 years later and now a lot of those layoffs that, that potentially could have happened back then are happening now. But I, it’s, that gets tricky when you start talking about the unions in Europe especially, because they still have quite a lot of power.

Joel Saxum: The interesting thing we heard at Sandia this week, Allen, was one of our respected friends in the blade world looking for a new engineering colleague, and the end of the job thing, or job posting basically was, Do they know what glass fiber is? Perfect. We’ll train him on the rest.

Allen Hall: That’s the reality though, Joel, is that people who have that knowledge are already working somewhere and it’s hard to find people to come into the industry and you’re willing to take about anybody at the minute that has particularly an engineering degree or any technical training in composites.

It’s going to get pulled into a company.

Philip Totaro: I don’t think it’s just them necessarily trying to get trained up with other OEMs or supply chain companies in particular, there’s also a pretty big demand amongst independent service providers or potentially even owner operators who would want to staff up with somebody that’s got expertise, particularly in how certain models of blades or whatever were designed and manufactured.

Yeah, so that could afford some of these people an opportunity to go in there and continue scaling up in the services business or the aftermarket parts businesses that are seeing a tremendous amount of growth right now globally.

Allen Hall: Did the blade mold getting broken in Cherbourg

Philip Totaro: a couple of months ago kick off this process?

Hard to say. To be honest, it let’s put it this way, it doesn’t help, but that was probably more of just an industrial accident sort of a thing, but it came at an unfortunate time when they were already facing so much pressure to deliver on Dogger Bank. And that’s the reality of that.

I think it just was unfortunate timing.

Joel Saxum: It’s a lot of weight, right? You get enough things stacked, and stacked, that was the first one on the bottom of the pile, and then you lose a couple of blades offshore, and the global market situation, some other things, once they compound the sum of the parts It’s a lot heavier than the parts themselves.

Allen Hall: When we come back from the break, I want to talk about our experience at the Sandia Blades Workshop this past week. And all the things that Joel and I learned and saw, and hopefully we’ll see you again in two years, because it was a really good conference.

Lightning is an act of God, but lightning damage is not.

Actually, it’s very predictable and very preventable. StrikeTape is a lightning protection system upgrade for wind turbines made by WeatherGuard. It dramatically improves the effectiveness of the factory LPS. So you can stop worrying about lightning damage. Visit weatherguardwind. com to learn more, read a case study and schedule a call today.

Allen Hall: All right, Joel. So we just spent the week at the Sandia blade workshop in Albuquerque, New Mexico. And we met with a lot of colleagues. It was like the creme de la creme of blade and wind engineers in one place, particularly in the United States. Many good presentations. Some more on the technical side, but others on the operational side and the operational Part is the one I think you and I were drawn into the most.

Joel Saxum: Yeah. You bring together Sandia brings together a lot of academics. It brings together our national labs here in the United States. But what they’re doing at these labs is they’re working on all kinds of crazy projects. Some of these labs are ones that have, they’ve worked on DOD things for the military.

Or they’ve worked on nuclear energy for other purposes. They’re working on looking at things in the grid and what is next? And so you bring those people together. And the people that want to hear from what’s happening at these labs are some of the best, like Allen said, some of the best engineers in blades or anything to do with wind turbines from the bigger, biggest and small operators all over the United States.

When you put those people together, you start getting into DTU and TU Delft and all kinds of other Universities that are doing project as well. So you end up, that the thing is put on by Sandia National Lab So you hear about a lot about what they’re doing and some of the other national labs and some of those Presentations get really in depth On the projects that they’re working on.

And because some people, people want to come in here. What’s the next thing. But then you also, since you have those great engineers sitting there in the crowd of course they take advantage of them being there. And then those awesome engineers are sitting on panels and they’re talking about the things that they’re doing to help other people out in the crowd.

So you have, the likes of next era and RWE these big players sitting up on stage. Telling everybody, basically, these are the problems we’ve encountered, this is the solutions that we had from them, and that’s, that tribal knowledge gets spread out amongst the crowd, so it’s like a, we always like to say, floating or rising waters floats all ships.

It’s a great conference, and there’s a lot of good information that goes on there.

Allen Hall: The one repeating focus, I thought, was the need to be very prescriptive on operations. Whether that be in the factory or out in the field there was a lot of emphasis on almost a checklist mentality of how to approach any sort of construction, any repair effort, any supply chain issue, any real large manufacturing is to eliminate it.

Problems by and variability because it’s the number of people coming in and out of any job site, whether it be in the factory out in the field, which should delineate what has to happen up front and to be very precise and controlled over it. And Matt Segala gave a really good presentation from EDF.

About how to do this on repairs and wow, there’s a lot of emphasis on the work ahead of the work, all the preparation and knowing to plan ahead for, Hey, we may need another lightning receptor. So we should have those on stock when the truck, as we get out to the site, we’re probably going to need them.

That’s a learned experience, but if you haven’t done it, like Matt has. You wouldn’t know, and then you get to site and not have all the tools and the equipment you need. And that was a really great insight, I thought.

Joel Saxum: Yeah, Matt’s presentation, in my opinion, was the best one of the whole week. And he brought that, I’m gonna give a presentation, and I’m gonna tell you exactly what you need, or what you can do, to get the same kind of results that we have.

And part of that is, is, I said tribal knowledge a little bit ago. Part of that is, is taking tribal knowledge and turning it into process and into knowledge that can be passed down, right? Because if it just exists in Allen’s head, or Phil’s head, or Rosie’s head, or my head, and I go do a thing, then I’m the only one that has that information, and I’m the only one who can replicate it.

It doesn’t make sense for a large organization, especially when we see in the wind industry, we see so many people moving from place to place. We talk about it with technicians, but it happens with engineers a lot as well. Oh, this person was at this. Now they’re over here or they were at the OEM and now they work for this operator or whatever that may be.

They’re Matt and that team at EDF with Ken Lee and Trevor Angle and all these other guys over there are taking what they know, what they’ve learned from experience, and they’re writing it down. They’re putting roadmaps down, processes down. Being able to make sure that everybody can follow along and get the same results time after time and what he showed us With some statistics and some metrics at the end of that presentation shows that EDF’s fleet is benefiting greatly from what they’re doing in that process driven basically program.

Philip Totaro: So Joel, what you’re saying is a company that digitizes its tribal knowledge, whether it’s from a consulting business or an owner operator is probably ahead of the curve. Absolutely. You can quote that.

Allen Hall: Rhodes had done that too. Yannis Petroms had discussed what they do with the rooms because they deal with a lot of technology and new people coming in and out.

And the robots are really intricate. There’s a lot going on there. Video pressure sensors, they’re pushing out fluids, curing things. And yeah, they’re using a little on the phone checklist to make sure everything gets done properly. The one he mentioned in particular was making sure that the closeout was put back on, on the blade, make sure the doors were all closed and fastened before they left.

They had to physically take a photo and record it before they left the blade. And. Things like that don’t seem obvious until you have something go wrong, and then they become really obvious and then you implement them. Joel it’s a learned experience. So you gotta climb back up that

Joel Saxum: tower? And to put the blade closer on?

Yeah, that sucks. No, I think it’s I think it’s something that the industry can definitely benefit from, and at this conference, it was a technical conference, we didn’t talk about some of the issues that we normally talk about when you get industry professionals together What is the technician pool look like in the shortage of blade repair knowledge?

We didn’t really touch on those things, but this what we’re talking about here is digitizing and making processes and these kind of things that can actually help scale the industry because you’re removing some of those learning barriers by providing tools. For people to execute in their daily jobs.

Allen Hall: Yeah, it’s a good conference. And the next

Joel Saxum: conference is in two years Joel? Yeah, they do Sandia every two years. It’s in the same town. It’s in Albuquerque. The Sandia lab is right there. So that makes sense for less spending for the Sandia people to be there. But Albuquerque, man, we were there.

The weather was fantastic the whole time. We had a great time with a bunch of our industry colleagues. ISPs, operators, there’s some blade repair companies there. There was of course, some of the operators we regularly get with some drone companies and catching up with colleagues is always great, but what happens in the conference and the technical situations is fantastic.

The things that you can learn sitting around a table, having dinner with friends from different operators as well. We sat with. BP and Orsted and Nextera and Elite Clean Energy all around in one group and the things that you can learn from each other, just being able to share, to break bread with each other is fantastic as well.

Allen Hall: That’s going to do it for this week’s Uptime Wind Energy podcast. Thanks for listening and please give us a five star rating on your podcast platform and subscribe in the show notes below to Uptime Tech News, our weekly newsletter. And check out Rosie’s YouTube channel, Engineering with Rosie. And we’ll see you here next week on the Uptime Wind Energy Podcast.

https://weatherguardwind.com/ge-vernova-restructures-offshore-wind/

Renewable Energy

California’s Next Governor?

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

What does the most affluent state in America need in its next governor? I’m pretty sure it not a Trump supporter.

Yes, we have traffic, which we hate. But that’s because everybody and his dog wants to be here for our economic opportunities and our natural beauty.

In general, we reject racism, ignorance, corruption, and environmental destruction.

Renewable Energy

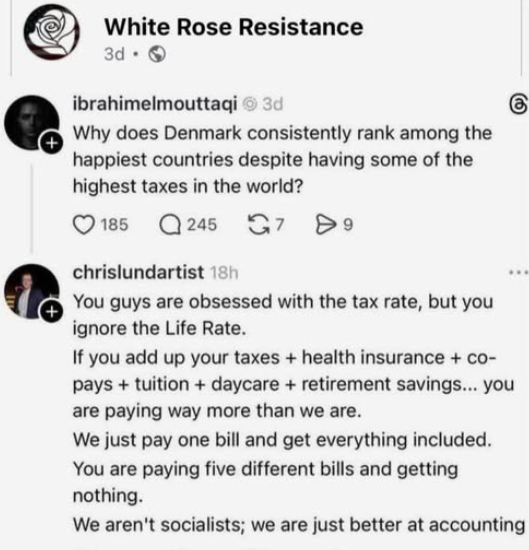

Understanding Social Democracy

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

I can’t swear that the content of the meme here is accurate; in fact, most affluent Scandinavians I run across admit that they pay higher taxes than Americans.

They claim that the attraction is that they aren’t forced to live among uneducated slobs where people are dying of treatable diseases with masses of impoverished people living on the streets.

Isn’t there something to be said for that?

Renewable Energy

What Kids Need from Their Parents

Well, here’s a controversial statement.

Well, here’s a controversial statement.

Apparently, there are people who believe kids should be raised by dishonest imbeciles.

https://www.2greenenergy.com/2026/03/05/what-kids-need-from-their-parents/

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits