PEAK Wind Masters Site and Turbine Selection

Lene Hellstern, Director of Engineering at PEAK Wind, discusses the complexities of onshore wind siting, the advantages of using LIDAR technology, and strategic considerations for turbine selection.

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Allen Hall: We’re back with Lene Hellstern, the Director of Engineering at PEAK Wind, and we’re talking about onshore wind siting, which is a really critical issue that a lot of operators have difficulties with. And I’ve seen it in the United States and it’s not good.

And I’m wondering from your perspective, what are some of the problems, Lene? Well first, welcome back to the podcast.

Lene Hellstern: Thank you. And thanks for having me repeat experience last time, so I hope so. I thought I’ll pop in again.

Allen Hall: Well, it’s good to have you back and thanks

Lene Hellstern: for coming to Copenhagen.

Allen Hall: Yeah, well we love Copenhagen.

It’s great. Uh, I just wish it was a little bit warmer. Yeah, the sun is terrific. Yeah. When you’re in it, well, at

Lene Hellstern: least I fixed that. Right. Yes. It’s not raining. It’s not raining. Yes.

Allen Hall: We, we quite enjoyed it. Uh, but I’m trying to get an understanding of what the underlying issues are with onshore wind siding and why some of the operators have difficulty later on.

Let’s just start with the sighting [00:01:00] itself. Yeah. Is usually, we’ll see a wind mast out on site for several months, maybe a year, maybe two years. To try to get some wind data. We would

Lene Hellstern: really like that. Yeah. Okay. But, uh, the preferable measurements are lidars.

Allen Hall: Oh, lidars. Yeah. I have not seen a lot of lidars in use.

Lene Hellstern: No. You, you need to get some more.

Allen Hall: Why?

Lene Hellstern: Um, because they reach higher.

Allen Hall: Okay.

Lene Hellstern: Um, and you can, uh, you can, you can move them around. Right. And the hassle of installing a Met Mass that’s a hundred meters tall, is, uh, is it a problem? Quite, uh. Quite it, it cost a lot more. Yes. Um, and, and the lidars, they, they just, they’re better and they measure higher.

And you can, you can have one sort of mother lidar and then you can move the other around and you can cover your wind resources and site suitability much better on the site. So I would definitely recommend

Allen Hall: lidars. Okay. How the lidars use a [00:02:00] good bit of power to make them run, correct? Yes. So you need a decent power source?

Yes.

Lene Hellstern: You do? Yes.

Allen Hall: Okay. Yeah. I, is that one of the difficulties why they don’t use a lidar? Is it just in a lot of remote areas, they don’t have the power source to run it?

Lene Hellstern: It could be, or it could be the, the lack of knowledge. Right. Traditionally we have used med masks, yes.

Allen Hall: Forever.

Lene Hellstern: Uh, so, so it could be, and then there are also some, um, uh, some issues with uncertainties because the lidar is the, the standards are not up to date.

I would say that’s the political way correct way of saying it. So. Eh, the standard actually introduces more uncertainty on the lidar that’s really not necessary to, due to a calibration with a me mast. Um, so that there’s some, there’s some things that needs to improve in that area

Allen Hall: because a lidar should be a lot more accurate than a met mast.

Lene Hellstern: Yes. Yeah. Yeah. But, but the, the downside of the lidar, so that, that is not often we see that, is if you don’t have enough particles in the air, you have [00:03:00] an issue because then you are, you’re simply not gonna be able to measure. The, the, uh, velocity of the particles because they’re not there. And then you have a low availability on your measurements.

But, you know, most places there’s, there’s a quite a lot of dust. There’s pollution. Um, so there, there are things in the air that we don’t see, but the lighter sea and then you can make the measurements.

Allen Hall: And as the hub heights have gotten taller, it gets a lot more difficult to get a met mass up that high.

So the lidars go can measure winds. How high up in the air? How many meters? I

Lene Hellstern: think at least 250 meters. Wow. And, and you want, you want to, you know, traditionally you would only measure at hop height, but you wanna measure at the, the, the rotor surface, right? So you wanna measure at tip height, and you wanna measure at lower top tip and lower tip to, to see what, for instance, what’s the wind share across your, uh, rotor disc.

Um, which

Allen Hall: you cannot really do with a met mast at all. You can’t do that. You have no [00:04:00] wind share knowledge. From that instrument? Sort of, yeah,

Lene Hellstern: you can, because you can make, you always, you, you have a met mass that’s at least at hop height, and then you have, uh, anemometers and wind veins and I don’t know what on all the way down.

Um, and you can with, without that equipment, you can, you can measure on the lower part of the rotor, but not the upper part. So, so you, you do get some possibilities to measure wind share, but not as good as, um, for instance, a lidar. Yeah.

Allen Hall: So how many lidars would you typically need on a 100 turbine site?

Lene Hellstern: Well, that depends.

Allen Hall: Okay.

Lene Hellstern: Because you have a, if you have complex terrain,

Allen Hall: right?

Lene Hellstern: Yeah. You may want a lot. Right. That’s what I

Allen Hall: was wondering if the more hills and valleys, the, the more lidars you will need, or more samples you’ll need, or maybe the longer duration you’ll need. Yes.

Lene Hellstern: Yeah. And you, you would wanna, you know, it’s always the best to measure it.

I think it’s [00:05:00] ideally five years. Nobody does that five years. Nobody. No, no. But you should at least have two, right?

Allen Hall: Yes.

Lene Hellstern: Uh, and then you should do a proper long term correlation. Um, so, so that’s, and how does

Allen Hall: that, how does that accomplish Right now, let’s just say we have a met mass. What I typically see is, has been a met mast out in the middle of the United States where the winds are pretty good.

Speaker 3: Yeah.

Allen Hall: And they have data. They have some data. Yeah. So typically I’ve seen them out there a year, maybe two years, and then. The, but the sites are massive. Yeah. They’re, they’re square miles. Yeah. Dozens of square miles. So it’s big.

Speaker 3: Yeah. I

Allen Hall: dunno whether it’s in kilometers, but a lot of square kilometers. So then they are trying to interpret interpretate that data that they have from the Met Mass on top of that.

I think they’re looking a little bit forward in terms of who, what other wind farms may be surrounding us in the next several years. Yeah.

Lene Hellstern: And that’s, that’s one of the challenges we have because there’s a lot that. Uh, you, there’s a lot of guessing.

Allen Hall: Yes.

Lene Hellstern: Um, and so if [00:06:00] you are planning a wind farm, you wanna know what goes on in the area.

You wanna map out the already existing turbines, uh, and what, what hop height, what rotor size, because you wanna be able to model them in your calculations.

Allen Hall: That was really good. Get to my question about how difficult this process is and how you try to address it. In the United States, we turn over wind turbines every 10 years, so there’s a repowering happening and.

Almost always, the rotor size gets substantially bigger. 20 to 30 to 50% bigger. Right. So there’s fewer turbines, same location. Yeah. And the turbines are roughly in the same spots, but they’re just bigger rotor diameters. How do you then prepare for that? Do you use the old data or is the old data even applicable?

If I’m really dramatically increasing the rotor size, do I need to be doing more? LIDAR measurements before I make that repower, or how do I even cite that? Right.

Lene Hellstern: Uh, you can, if you have some good SCADA data from your turbines, you can do some [00:07:00] modeling. And many of the sites actually have a met mast. They do a lot Yeah.

As a reference, right? Yes. Right. But that will be on it, it will have sectors where there’s a lot of weight from the existing.

Allen Hall: Okay.

Lene Hellstern: So, and so I would, I would, I would try, I would filter your SCADA data from your site and see if, can I, can I use this? I’ll take a look at the mid mass state and see, can I use this?

If not, I’ll start a me mass campaign. Now the problem is if you’re reusing the spots now, well first of all, that’s a little bit difficult reusing because your foundation is dimension to an old generation turbine. Uh, let’s say take someone a hundred, a hundred, uh, meter rotor, right? Right. But now you’re going up in size.

Um, so that means everything gets heavier and bigger, right? So your foundation may not be suitable. The old foundation, normally they’re over dimension. So you can, you can extend life or you could repower on them, but you would want a bigger turbine. [00:08:00] So you don’t necessarily want to use the opposition, right?

And then you would wanna know what is in the pipe. You know, when can I get my, when can I start digging? Right? When can I start installing? Uh, what is in the pipeline at that point from the OEMs? Because sometimes it actually takes five years from, you start planning until you, you, you start digging. And in that time, if you, you, if you space with today’s models, you are gonna have two shorter distance between the turbines because the new turbines on the market that you would wanna buy has increased significantly.

Um,

Allen Hall: and that’s a real problem. Yeah. Like that, this, this. Between the, the siting time, the met mass, the LIDAR data, getting enough data and having to make the decision about a turbine relatively early because the production lines are not operating at full capacity right now. Yeah. It’s hard to get a turbine.

So you are 3, 4, 5 years out. Yeah. How do you plan for that on an onshore site?

Lene Hellstern: Well, [00:09:00] you, you gotta guess a rotor and guess a, a turbine site. Okay. Right, right. So, but

Allen Hall: do, do the engineering staffs that a lot of operators have that inside knowledge because it seems like smaller operators, I’m, I’m not the urals of the world, have power and they can see inside the factories and they have a really good connection and they develop that connection over a long, many, many years.

Speaker 3: Yeah.

Allen Hall: Where newer operators usually do not have that sort of insight. So where do they go to get help?

Lene Hellstern: Well, well, they could go to, right? We could help them a little bit, but. You can also look, if you look at the evolution of the turbines, you can, and I, I’m, I’m hoping we are at a little bit of a pause here in the, in, in the growing size.

So we, we can refine the turbine, we can refine our manufacturing facilities. We, we get better at service and installation. But you can pretty much, you know, guess the rotor. Uh, I’ve, I’ve done that a lot in, in this job and my previous job, because you [00:10:00] look at, if you look at when the. When did what? Come on the market and from what, OEM.

Right. And then you, you know, there’s, there’s other topics you need to look into for, for instance, site suitability. Right? Right. What are, what are the conditions on the site? Um, are you a, we, we categorize in different classes. I, e, c, 1, 2, 3, um, or turbulence classes. A, B, C. And then there’s the, the class I like the least that is the Class S.

Which is special. And then you never know what it is before you start digging in all the paper. Um, but, but you, that’s sort of the first things you need to find out. What class are you? And then there’s a small in that because, um, you may think you are a, a class two or have a class two side, but then it turns out that your air density is unbelievably low.

So sometimes you can actually squeeze in a class three. Turbine on a class two [00:11:00] side and get that much more production.

Allen Hall: Do a lot of operators know that?

Lene Hellstern: No.

Allen Hall: I wondered. Okay. Yeah. Well

Lene Hellstern: maybe the, it’s not so much the operators. It’s the developers. Developers. Sure. Yeah, yeah, yeah. That has to, to, to dig a little bit more into the lovely engineering science around turbines and.

And, and then do more site suitability because you can actually improve your, the value of your project quite significantly.

Allen Hall: That’s what I wonder if, if you spend a good extra amount of time maybe spending a little more money to get LIDAR measurements Yeah. And to do them for a slightly longer period of time, does that have a return on investment?

Lene Hellstern: You get, you get less uncertainty. Right. And then I think some of the issues or some of the mistakes that the developers do, they. They do a wind, they do a, a production estimate, but that is not the same as a site suitability or uh, [00:12:00] you know, also, some people also think if I do a wind resource assessment, then I’m covered.

No, because that is the input to the site suitability. Now you also need to do the site suitability. So you know, I would start out doing a wind resource assessment, right? Then I would do a site suitability and then you do your production calculator.

Allen Hall: And how long does that process take, generally?

Lene Hellstern: Oh, that’s always a cue.

So it could take, uh, it depends on who you use for this, right? But it could take four to to eight weeks.

Allen Hall: Okay. That’s not horrible. No,

Lene Hellstern: no, no.

Allen Hall: Alright, so it, it is relatively efficient compared to other things that happen in wind.

Lene Hellstern: Yeah. If you are have a complex site, it can take longer because you need to run a lot more calculations due to, uh, the comp complexity of the terrain, right?

Mm-hmm. You can have issues with inflow, angles, uh, ware, wind share, uh, [00:13:00] all the lovely technical things. Yeah.

Allen Hall: Well, and because we’ve developed so many sites to date, all the best wind sites have turbines in them mostly right now, and. We’re, we’re starting to get along the fringes of that good wind area.

Yeah. And in some cases, does that change the way you do the analysis and do the approach?

Lene Hellstern: Yes, but, um, some of us have done that for a long time because it’s not good enough to have good wind if you don’t have good grid. Um, so, so for me, a good wind side, you know, we, I, I spoke with someone yesterday about.

The best, uh, uh, wind resource in Sweden. Um, but, but if that area doesn’t have a good grid, then you know it, I can’t harvest the wind. Right. Right. Um, and it’s the same in, in the US right? You, you have some grid issues. Um, so we have a lot of

Allen Hall: grid issues. Yeah.

Lene Hellstern: And if you don’t, everything is [00:14:00] combined.

Everything works closely together, right. Uh, the technical, the commercial and the finance. So if, if, if that is not. Well, um, covered in a, in a, or, uh, investigated in a project, you don’t have a good project. Um, is

Allen Hall: the grid the limiting factor in a lot of onsite onshore sites?

Lene Hellstern: I think the world is becoming more and more electrical, which it is, which I think it’s good.

Mm-hmm. And I don’t think that they, we can point at any government that was super duper on, um, expanding the grid. Um, no. I know there are issues in Texas. There are also issues in Denmark where I’m from. There are, yes, there’s issues in Europe. So, um, we, we need, we need massive in investments from the government to build out this grid.

It’s, it’s not, um, enough to say we want clean energy and then do nothing. Right. Well

Allen Hall: this is where, where, where the ons onsite versus the onshore versus the offshore comes in. Yeah. [00:15:00] Is the grid.

Speaker 3: Yeah.

Allen Hall: So in the US and other places, uh, there’s been. A, a lot of concern about offshore wind, but offshore wind, you can get to a grid relatively easily.

Yes, usually. Yeah. Yeah. And it’s less bureaucracy to lay cable in the ocean than it is to run transmission lines over land.

Speaker 3: Yeah.

Allen Hall: So is this starting to flip a little bit because of the onshore limitations in the grid that we’re seeing more offshore, just because it’s easier.

Lene Hellstern: Well in Europe, but I would not say that in the us Right.

But, uh, but, um, um, it, it, it is easier, but it’s also much more complex to put up these, uh, offshore projects. They are in development for many, many years compared to onshore.

Allen Hall: Right.

Lene Hellstern: So, so onshore is a little bit of a, depending on country you are in, if it’s overpopulated right? It’s, it’s difficult, but it’s, it’s a much more of a quick fix, uh, [00:16:00] onshore.

For, uh, lack of energy. Right, right. But, but it just requires it, yes, it requires the grid and yes, it requires that you don’t do it in a popula populated area. We don’t want to do that. Right, right. We want, we want the open fields, um, where we’re not disturbing anyone. True. Yeah.

Allen Hall: True. But we also want infinite electricity.

Absolutely. So you have to weigh those two off.

Lene Hellstern: I, but I think the turbines are beautiful. So I would, I would love to be able to see one from my house, but I can’t. Yeah.

Allen Hall: We have actually quite a few we can see from our, from our house. Yeah. Yeah. And no one complains. No. They complained for the first few weeks after they were installed and after that it’s been completely quiet.

Yeah. But,

Lene Hellstern: but I do understand if you place turbines too close to a house Right. Sure. That, how that can be disturbing. Sure. Um, I, I totally understand that. Yeah.

Allen Hall: Can we talk about AI data centers and independent grids and how that’s factoring [00:17:00] into some of the decisions about where to place wind sites?

Because it does seem like in a lot of places in the world, these AI data centers are going to go in. Yeah. And they’re making decisions about using natural gas to power the turbines or using wind and solar and a little bit of battery to, to run these centers. Yeah, but that doesn’t necessarily. Wire a connection to the grid.

Does that make it easier in a sense that you don’t necessarily have to have a grid connection, you could put something out in a remote area that it still had good wind and still has good solar with a little bit of battery? And are you starting to hear more action that way, or interest in that?

Lene Hellstern: I’ve, I’ve seen that there’s been, uh, quite some centers that has, uh, made, uh, PPA agreements with, with wind turbine owners.

But they are normally not super close, uh, uh, located to the wind farm. Okay? And I would also say that I would find it a little bit difficult, [00:18:00] uh, if they were remote, because you need a, you need a constant power source and, and the wind doesn’t blow all the time, right? No. So you need, you need a lot of, uh, combination mechanisms, right?

You do to make sure everything runs stable.

Allen Hall: But you may not have neighbors in that case because you could select a site that’s a little bit further away from. Society in a sense. Yeah. Where the, the wind siding may be a little more complicated though because we, we probably haven’t looked in those areas because it’s not connected to the grid.

So you may not have historical wind data doesn’t make the problem just bigger. So I do think in the United States you see like Amazon and Meta and Google talking about using wind and solar to power some of these data centers. Yeah.

Lene Hellstern: And, and they are, and I know that there are, uh, agreements that has been signed.

But I, I am, I don’t think they are close, uh, you know, in close proximity necessarily.

Allen Hall: Okay.

Lene Hellstern: But of course the, the, the electricity needs to be to be transported in the grid. Right. [00:19:00] And it’s not like it’s a microgrid around the data center.

Allen Hall: I think you may see more microgrids.

Lene Hellstern: Okay. Well that could be interesting.

Well, that’s what

Allen Hall: I’m wondering because there may be more microgrids that won’t even be microgrids because the amount of power that they’re gonna use, they’re gonna be decent sized grids.

Speaker 3: Yeah.

Allen Hall: That. Th that becomes even a more difficult engineering challenge.

Lene Hellstern: Well, I think it’s gonna be too expensive.

Allen Hall: You think so?

Yeah. Compared to natural gas or just because No, just,

Lene Hellstern: uh, buying, doing a PPA with a wind farm that may be a hundred kilometers away. Yeah. Right.

Allen Hall: Okay. Um, well that’s interesting. Yeah.

Lene Hellstern: I think the whole, um, uh, burying the cables in the, you know, the whole installation, uh, is, is simply, it’s simply to, uh, it’s complicated cap.

Is too high.

Allen Hall: Okay.

Lene Hellstern: It’s, it’s much more affordable just to buy a PPA.

Allen Hall: Yeah. It may be. Yeah.

Lene Hellstern: Yeah.

Allen Hall: Okay. Well this is, this is fascinating. Can I pick your brain or bother you just a little bit longer?

Lene Hellstern: Yeah, [00:20:00] yeah, sure. Okay.

Allen Hall: So

Lene Hellstern: it depends on the time. Yeah.

Allen Hall: We got 20 minutes. Good. Can I steal 10?

Lene Hellstern: Yes, sure.

Allen Hall: Okay.

Lene Hellstern: This is not my core area, just so you know.

Allen Hall: No, no, no. I wanna, I wanna get, I wanna get back into Yeah. The, the meat here, which is turbine selection.

Speaker 3: Yeah.

Allen Hall: I have my LIDAR data. Mm-hmm. I have my MET Tower data. I have say I have two years. I am really the best wind resource knowledge operator developer that you’re gonna meet.

Speaker 3: Yeah.

Allen Hall: Great. Super. What do I do next in terms of picking a turbine?

How do I even do that? And how does that process look like if I’m talking to OEMs about something that’s still three years from being developed?

Lene Hellstern: Well, you need to start, you, you need to have your planning, uh, your permits in order.

Allen Hall: Sure.

Lene Hellstern: So depending on what country you are in some operate, what you need to apply for the [00:21:00] specific location of the turbines more, it’s more a box.

Uh, so it’s, you say, I am, I wanna apply for 300 megawatt, 500. Uh, please. In, in this area. Um, so then you start looking at your site, suitability, uh, what, what boundaries am I working within? What is my average wind speed in different, these different heights? Uh, what’s more, how do I get levelized cost of energy as low as possible?

Because some people still sit and look at the net capacity factor, but those days are over, right? They are,

Allen Hall: yes.

Lene Hellstern: Yeah. So when, when all alarms should go up, if they say. Good lift capacity factor. Yeah. Super. What’s your live life cost of energy there? Um, so, so then you, now you start, you have a good idea on what kind of a turbine class should I look at?

Then you start looking at who is, do you wanna do self service? Do you wanna have a full service agreement?

Allen Hall: Exactly. That’s what Im really wondering how that works then, because if I [00:22:00] know the basics of the wind site, do I just. Put a proposal together and slide it to Vestus and slide it to ge, or is there still more I need to do before I start talking to them?

Lene Hellstern: You need, you need to ask you yourself and your organization. Okay. Or PEAK. Yeah, but, but we would ask you as well, what is your o and m strategy, right? Do you wanna do self perform? Do you want a full service agreement? What, what’s, how risky do you wanna make it? Is that

Allen Hall: a deciding factor in determining what turbine you want to purchase?

Yeah.

Lene Hellstern: Because then you may not need D-O-E-D-O-E-M to have a service organization close to your site. Right? Let’s say, okay, so

Allen Hall: let’s say you choose vestus because they have a, they want to sell you a full service agreement, generally sPEAKing. Yeah. Where a, a GE typically doesn’t care or not so involved in that.

Lene Hellstern: Okay. But then, but you wanna know, do they have a service organization close to right. Right, right. Or are they gonna re uh, are they, do they need to build it? Right? Is this a new [00:23:00] platform? Do they not have any experience with this platform, the people in this area? Because then you, you know, that’s always, so it’s teething issues, right?

Allen Hall: Sure.

Lene Hellstern: Yeah. So,

Allen Hall: so how does that play into your decision making then?

Lene Hellstern: Well, you know, if you have a, if you have, let’s say, four volumes in this area,

Speaker 3: right?

Lene Hellstern: Yeah. And then you had, you, you look at what, what do they, what turbines do they offer? What service agreements can you get? What availability, you know, how does the contracts, you wanna benchmark the TSAs and the SMAs?

Yes. Um, and to see what kind of, who’s the best player here? There’s a lot of pieces to the puzzle. Well,

Allen Hall: that, that’s exactly what I wanted to get to was, I’m trying to understand how deep you’re going in this. So you’re actually looking to see if they have a service site nearby? Yes. And what the service people have been exposed to in terms of turbine type.

Yeah. And also you’re going a little bit deeper to see how successful they have been. Maybe you, you’ve called the sites

Lene Hellstern: around if I have that information. Yes. Yeah. [00:24:00] Okay.

Allen Hall: Yeah. So you’re making a lot of decisions not based upon necessarily what the OEM is offering as a product, but you’re also looking at what does the next 10, 20, maybe even 30 years looks like.

Lene Hellstern: Yeah. And then you wanna know what, you know, what, what turbines, what pipeline is there, and then you wanna do the tender. Right,

Allen Hall: right.

Lene Hellstern: Let’s say now you’re down to three because the fourth one, that, that was a no-go. Right? So now you have, that’s why I always, I say four turbines per site. You need to pick, pick four different OEMs.

Now you’re down to three. Right? And then you, you, you, you, you issue a tender and you, you get the proposals in. Okay? And then you, you start negotiating and you do your tech, your technical due diligence, right? To sort of dig a little bit deeper and understand the OEMs right. Also give them a chance to say.

Hey, this was an issue before, but we fixed this problem and you can see it documented. Oh, you go, yeah, but you’re still, you’re not there. So I need to account for that. So then you have a dialogue with them, and then, [00:25:00]then you have, you, you then the third one is too high and now you have or can’t deliver, or you know,

Allen Hall: doesn’t have a production schedule that meets your deeds.

Lene Hellstern: Yeah. Yes, exactly. And now you’re down to two, and then may the best one win. Right.

Allen Hall: Okay. So you’re talking about. Several months of gyration. Yes. Meeting with the OEMs or OEMs coming to you even to give their pitch. Meanwhile, you’re evaluating their technical expertise about their turbine, and you’re questioning how the previous generation of those turbines have performed looking forward to say, have you fixed the the existing problems?

And what does the next generation look like? Yeah.

Lene Hellstern: Oh, well, what did they look into? Developing a new

Allen Hall: platform.

Lene Hellstern: Okay. Right.

Allen Hall: So are you thinking about risk in terms of new technology? I’ll, I’ll throw the easy one at you two piece blades.

Lene Hellstern: No, thank you.

Allen Hall: Okay. That’s a, that’s a good response. Yeah. Because I think a lot of, there was just a lot of unknowns about that.

Speaker 3: Yeah.

Allen Hall: Yeah. And then now that we have some service history, yeah. We may wanna rethink that. Yeah. Are there other types of [00:26:00] technologies that would lend themselves to requiring further review?

Lene Hellstern: Yeah, but there’s, I, what I’m hoping is that, that maybe we can pause a little bit on the sizing thing in the. Right.

And then refine the components a little bit more and then, and be more innovative, um, instead in the components. In the components, yeah. And, and improve the manufacturing quality installation service. Right? Because, um, sometimes what I see in the industry is not, it’s an old component, but actually it’s the people that’s the issue, right?

Mm-hmm. We don’t, we are not, we are not trained, you know, we don’t have the technicians trained really in a. We don’t have the people in the manufacturing trained well enough, and so, so we make mistakes. So, and

Allen Hall: are you looking for OEMs that are doing more reflective activity at the moment that they’re basically causing new designs?

And then we always do that, that when we

Lene Hellstern: always look at, when we do technical diligence, how is the training [00:27:00] in the, in the manufacturing, you know, what kind of programs do the different people need to go through? How do you get to a seniority? How do they train them? How do they test them? How many years does it take, right?

Because you can’t do things in five minutes.

Allen Hall: Right?

Lene Hellstern: What’s the turnover at a manufacturing plant?

Allen Hall: See? But this is why you would choose PEAK wind to help you do that process. Because I don’t think a lot of developers, and especially in the United States where we see a lot of it, I see a lot of it developers are about putting turbines in the ground.

Yeah. And then selling that farm to the next owner, right? Yeah. So those long-term agreements don’t really play into a lot of this, and from what I’ve seen, but I think in Europe it’s a lot different.

Lene Hellstern: Yeah. No, but we also have, you know, there are different concepts. There is a built to sell.

Allen Hall: Yes. Right? Yeah.

Lene Hellstern: That’s, then you, you, they, they tend not to, uh, be so focused on the technology. Right, right, right. And then there’s the people that built to keep, right, right. And you could, if you can see, they, that was their intention. And then they [00:28:00] ended up having to divest anyway. Then, you know, that they, they, they probably did, did a little bit more work on the technology side.

Which

Allen Hall: one’s more successful? Build to sell or build to keep

Lene Hellstern: build, to keep

Allen Hall: built, to keep has better power production, more revenue,

Lene Hellstern: less uh, downtime.

Allen Hall: Less downtime. Yeah. Because they’ve done their work upfront and many

Lene Hellstern: of them Yes. Have have done it. Yeah.

Allen Hall: Mm-hmm.

Lene Hellstern: So, but, but developers can still do, uh, build to sell.

Sure. But then they need someone with the technol technological glasses to come in and help.

Allen Hall: Sure, sure. But that’s where PEAK wind comes in, because. You carry those people on your staff, you, your PEAK wind’s full of experts.

Lene Hellstern: We would love to, yes.

Allen Hall: So that you can immediately tap the group of experts about the different aspects of this new development.

Yeah. From training to warranties to technology to just generally how an OEM performs and Yeah, but it’s

Lene Hellstern: also, it’s the technology [00:29:00] commercial finance, right? Bingo, finance. Yeah. They go, they go together. Right, right. It’s not a. Enough to have a brilliant gearbox that can last a hundred years if you only need it for 35.

Right. That’s true. And you paid a fortune. Right. That true. That’s just not a good business case.

Allen Hall: Right. And there are turbine manufacturers that have that model that do do that still. Yeah. Yeah. This is fascinating and I, I appreciate your time. Every time we talk, I just get more in depth of what is happening and, and where we can get better as an industry.

Yeah. And that’s what PEAK wind is all about. Yes,

Lene Hellstern: but we are really good already. We just need to get, we are good. Better. Yeah. Yeah.

Allen Hall: We do need to get better. And we do, I think we do need to take a pause.

Lene Hellstern: Yeah.

Allen Hall: So how do people get a hold of PEAK wind and to tap your expertise and attack, to bring in the expertise of your team?

Lene Hellstern: Well, we have a, a webpage, uh, where you can contact us through, or, uh, LinkedIn. I am on LinkedIn, so feel free to send me a, a message. Um. [00:30:00] So, and reach out to us and we would love to help. We also have a, we have offices in Boston and uh, uh, Texas. Uh, we also have Oh, around the world. Yeah. Canada. So Taipei, yes.

Yes. Re and

Allen Hall: congratulations. I think you just won a, was it in Taiwan? Uh, an offshore site Yes. That you’re gonna be operating or managing Meow.

Lene Hellstern: Yeah.

Allen Hall: Yes. Congratulations on that. Thank you. That’s very exciting. That’s

Lene Hellstern: my lovely C in asset management. Yeah.

Allen Hall: Very nice. Yes. So Lene, thank you so much for being back on the podcast and we have to have you back on again ’cause there’s so much to talk about and win.

And it’s great to talk to someone who has been around and has seen it and has done it. Uh, it’s, thank you for having, it’s such a tremendous learning experience.

Lene Hellstern: It was a pleasure. Thanks.

https://weatherguardwind.com/peak-wind-site-turbine/

Renewable Energy

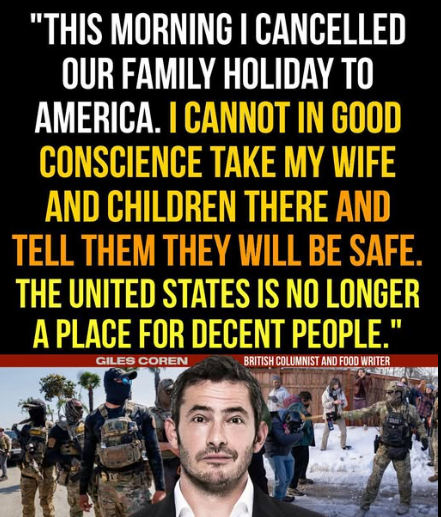

How Is U.S. Insanity Affecting Tourism?

It’s probably a bit too soon to have useable statistics on this subject, but it’s certainly not too early to apply some common sense.

It’s probably a bit too soon to have useable statistics on this subject, but it’s certainly not too early to apply some common sense.

There are at two factors at play here:

1) America is broadly regarded as a rogue country. Do you want to visit North Korea? Do Canadians want to spend money in a country that wants to annex them?

2) America is now understood to be unsafe. Do you want to visit Palestine? Ukraine? Iran?

Renewable Energy

Commercial Solar Solutions: Real Case Studies by Cyanergy

The post Commercial Solar Solutions: Real Case Studies by Cyanergy appeared first on Cyanergy.

https://cyanergy.com.au/blog/commercial-solar-solutions-real-case-studies-by-cyanergy/

Renewable Energy

Inside ATT and SSE’s Faskally Safety Leadership Centre

Weather Guard Lightning Tech

Inside ATT and SSE’s Faskally Safety Leadership Centre

Allen visits the Faskally Safety Leadership Centre with Mark Patterson, Director of Safety, Health, and Environment at SSE, and Dermot Kerrigan, Director and Co-Founder of Active Training Team. They discuss how SSE has put over 9,000 employees and 2,000 contract partners through ATT’s innovative training program, which uses actors and realistic scenarios to create lasting behavioral change across the entire workforce chain, from executives to technicians. Reach out to SSE and ATT to learn more!

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

Welcome to Uptime Spotlight, shining Light on Wind. Energy’s brightest innovators. This is the Progress Powering tomorrow.

Allen Hall: Mark and Turnt. Welcome to the show. Thank you.

Mark Patterson: Thank you.

Allen Hall: We’re in Scotland, present Scotland and per Scotland, which is a place most people probably haven’t ventured to in the United States, but it is quite lovely, although chilly and rainy. It’s Scotland. We’re in December. Uh, and we’re here to take a look at the SSE Training Center.

And the remarkable things that active training team is doing here, because we had seen this in Boston in a smaller format, uh, about a year ago almost now.

Dermot Kerrigan: Just Yeah,

Allen Hall: yeah. Six months

Dermot Kerrigan: ago.

Allen Hall: Yeah. Yeah. It hasn’t been that long ago. Uh, but IC was on me to say, you gotta come over. You gotta come over. You gotta see the, the whole, uh, environment where we put you into the police room and some of the things we wanna talk about, uh, because it, [00:01:00] it does play different.

And you’re right, it does play different. It is very impactful. And it, and maybe we should start off first of Mark, you’re the head of basically health and safety and environment for SSE here in Perth. This is a remarkable facility. It is unlike anything I have seen in the States by far. And SSE has made the commitment to do this sort of training for.

Everybody in your employment and outside of your employment, even contractors.

Mark Patterson: We have been looking at some quite basic things in safety as everybody does. And there’s a fundamental thing we want to do is get everybody home safe. And uh, it’s easier said than done because you’ve gotta get it right for every single task, every single day.

And that’s a massive challenge. And we have like 15,000. 15,000 people in SSE, we probably work with about 50,000 contract [00:02:00] partners and we’re heavily dependent, uh, on get our contract partners to get our activities done. And they’re crucial.

Speaker: Mm-hmm.

Mark Patterson: And in that it’s one community and we need to make sure everybody there gets home safe.

And that’s what drove us to think about adding more rules isn’t gonna do it. Um, you need to give people that sense of a feeling, uh, when a really serious sense of cars and then equip them with tools to, to deal with it. So. We’ve all probably seen training that gives that sense of doom and dread when something goes badly wrong, but actually that needs to be.

Coupled with something which is quite powerful, is what are the tools that help people have the conversations that gets everybody home safe. So kind of trying to do two things.

Allen Hall: Well, SSC is involved in a number of large projects. You have three offshore wind farms, about a more than a thousand turbines right now.

Wind turbines onshore, offshore, and those offshore projects are not easy. There’s a lot of complexity to them.

Mark Patterson: Absolutely. So look, I I think [00:03:00] that’s, that’s something that. You’ve gotta partner with the right people. If you wanna be successful, you need to make it easy for people to do the right thing. Yeah, as best you possibly can.

You need to partner with the right people, and you need to get people that you need to have a sense that you need to keep checking that as you’re growing your business. The chinks in your armor don’t grow too. But fundamentally there’s something else, which is a sense of community. When people come together to, to do a task, there is a sense of community and people work, put a lot of discretionary effort into to get, uh, big projects done.

And in that, um, it’s a sense of community and you wanna make sure everybody there gets home safe to their friends and family. ’cause if we’re all being honest about it, you know, SSE is a brilliant company. What we do is absolutely worth doing. I love SC. But I love my family a fair amount more. And if you bought into that, you probably bought into the strategy that we’re trying to adopt in terms of safety.

Uh, it’s really simple messaging. Um,

Allen Hall: yeah. That, that is very clear. Yeah. And it should be [00:04:00]well communicated outside of SSEI hope because it is a tremendous, uh, value to SSE to do that. And I’m sure the employees appreciate it because you have a culture of safety. What. Trigger that. How long ago was that trigger?

Is this, this is not something you thought up yesterday for sure.

Mark Patterson: No, look, this, the, the, what we’ve done in the immersive training center, um, really reinforces a lot of things that we’ve had in place for a while, and it, it takes it to the, the next level. So we’ve been working probably more than 10 years, but, uh, certainly the.

Seven years we’ve been talking very much about our safety family, that’s the community and SSE with our contract partners and what we need to do. And part of that is really clear language about getting people home safe. Uh, a sense that you’ve, everybody in it that works with us has a safety license. And that license is, if it’s not safe, we don’t do it.

It’s not a rural based thing. It’s how we roll. It’s part of the culture. We’d, we, uh, have a culture where, and certainly trying to instill for everybody a culture. Where [00:05:00] they’ve got that license. If, if they think something’s not right, we’ll stop the job and get it right. And even if they’re wrong, we’ll still listen to them because ultimately we need to work our way through, right?

So we’ve been, we’ve thought hard about the language we wanted to use to reinforce that. So the importance of plan, scan and adapt. So planning our work well, thinking through what we need to do. Not just stopping there though, keeping scanning for what could go wrong. That sense that you can’t remember everything.

So you need to have immediate corrective actions and that immediate sort of see it, sort of report it. If you see something that isn’t right, do something about it. And that sense of community caring for the community that you work with. And those are the essence of our, our language on safety and the immersive training.

Uh, is not trying to shove that language down everybody’s throats again, particularly our contract partners, but it’s, it’s helping people see some really clear things. One is if a [00:06:00] really serious incident occurs at what, what it feels like here. And I’ve spent a lot of time in various industries and people are different when they’ve been on a site or involved when there’s been a really serious incident and you need to do something to.

Get that sense of a feeling of what it feels like and actually make people feel slightly uncomfortable in the process. ’cause that’s part of it,

Allen Hall: right? Yes.

Mark Patterson: Because you know,

Allen Hall: you remember that.

Mark Patterson: You remember that. Yeah. We’ve had, you know, we’ve had people say, well, I felt very uncomfortable in that bit of the training.

It was okay. But was, I felt very uncomfortable. And you know, we’ve talked about that a lot.

Allen Hall: Yeah.

Mark Patterson: We know you kinda should because if there’s something wrong with you, if you don’t feel uncomfortable about that. But what’s super powerful on the guys in at TT do brilliantly. Is have facilitators that allow you to have that conversation and understand what do you need to do differently?

How do you influence somebody who’s more senior? How do you, how do you bring people with you so that they’re gonna [00:07:00] do what you want ’em to do after you’ve left the building? And. Just pointing the finger at people and shouting at them. Never does that. Right? Uh, rarely does that. You’ve gotta get that sense of how do you get people to have a common belief?

And,

Allen Hall: and I think that’s important in the way that SSE addresses that, is that you’re not just addressing technicians, it’s the whole chain. It’s everybody is involved in this action. And you can break the link anywhere in there. I wanna get through the description of why that. Process went through ATTs head to go.

We need to broaden the scope a little bit. We need to think about the full chain from the lowest entry worker just getting started to the career senior executive. Why chain them all together? Why put them in the same room together? Yeah. Why do you do that?

Dermot Kerrigan: Well, behavioral safety or behavioral base safety kind of got a bad rep because it was all about.

If we could just [00:08:00] make those guys at the front line behave themselves,

Allen Hall: then everything’s fine,

Dermot Kerrigan: then everything’s fine.

Allen Hall: Yes.

Dermot Kerrigan: But actually that’s kind of a, the wrong way of thinking. It didn’t work. I, I think,

Allen Hall: yeah, it didn’t work.

Dermot Kerrigan: What the mess, the central message we’re trying to get across is that actually operational safety is not just the business of operational people.

It’s everybody’s business.

Allen Hall: Right.

Dermot Kerrigan: You know? Um, and. Yeah, everybody has a role to p play in that, you know? Right. So site based teams, back office support functions, everybody has a role to play. And, you know, there’s a strand in, in this scenario where, uh, an incident takes place because people haven’t been issued with the right piece of equipment.

Which is a lifting cage.

Allen Hall: Yes.

Dermot Kerrigan: And there’s a whole story about that, which goes through a procurement decision made somewhere where somebody hit a computer and a computer said no because they’d asked for too many lifting cages when they, somebody could have said, you’ve asked for five lifting cages, it’s takes you over the procurement cap.

Would four do it? [00:09:00] Yes, that would be fine. That would be fine. Yeah. As it is, they come to a crucial piece of operation. This incr this, you know, this crucial piece of kit simply isn’t there. So in order to hit the deadline and try and make people happy, two ordinary guys, two technicians, put two and two together, make five, and, and one of them gets killed, you know?

Yeah. So it’s, we’re, we’re trying to show that, that this isn’t just operational people. It’s everybody’s business.

Mark Patterson: Well, that’s why we worked with you in this, because, um, we saw. Why you got it in terms of that chain? Um, so in, in the scenario, it’s very clear there’s a senior exec talking to the client and actually as SSE.

We’re sometimes that client, we’ve got big principal contractors that are doing our big construction activities. We’ve got a lot in renewables and onshore and offshore wind obviously, but, and the transmission business and in thermal, so, uh, and distribution. So I’ll list all our businesses and including customer’s business, but we’ve got some big project activities where we’re the client sometime we’re the principal contractor [00:10:00] ourselves.

And we need to recognize that in each chain, each link in that chain, there’s a risk that we say the wrong thing, put the wrong pressure on. And I think what’s really helpful is we have in the center that sort of philosophy here that we get everybody in together mixed up. Probably at least half of our board have done this.

Our executive team have all done this. Um, people are committed to it at that level, and they’re here like everybody else sitting, waiting for this thing to start. Not being quite sure what they’re gonna go through in the day. Um, and it’s actually really important you’ve got a chief exec sitting with somebody who’s, um, a scaffolder.

That’s really important. ’cause the scaffolder is probably the more likely person to get hurt rather than chief exec. So actually everybody seeing what it’s like and the pressures that are under at each level is really important.

Allen Hall: SSC is such a good example for the industry. I watched you from outside in America for a long time and you just watch the things that happened.

[00:11:00] Here you go. Wow. Okay. SSC is organized. They know what they’re doing, they understand what the project is, they’re going about it. Mm-hmm. Nothing is perfect, but I, I think when we watch from the United States, we see, oh, there’s order to it. There’s a reason they’re doing these things. They’re, they’re measuring what is happening.

And I think that’s one of the things about at t is the results. Have been remarkable, not just here, but in several different sites, because a TT touches a lot of massive infrastructure projects in the uk and the success rate has been tremendous. Remember? You wanna just briefly talk about that?

Dermot Kerrigan: Yeah. But we, we run a number of centers.

We also run mobile programs, which you got from having seen us in the States. Um, but the first, uh, center that we, we, we opened was, was called. Epic, which stood for Employers Project Induction Center, and that was the Thames Tideway Tunnel Project, which is now more or less finished. It’s completed. And that was a 10 year project, 5 billion pounds.

Allen Hall: Wow.

Dermot Kerrigan: Um, [00:12:00] and you know, unfortunately the fact is on, on that kind of project, you would normally expect to hurt a number of people, sometimes fatally. That would be the expectation.

Allen Hall: Right. It’s a complicated

Dermot Kerrigan: project, statistic underground. So, you know, we, and, and of course Tide, we are very, very. Very pleased that, uh, in that 10 year span, they didn’t even have one, uh, serious life-changing injury, uh, let alone a fatality.

Um, so you know that that’s, and I’m I’m not saying that what ATTs work, uh, what we do is, is, is, is directly responsible for that, but certainly Epic, they would say Tideway was the cornerstone for the safety practices, very good safety practices that they, they put out. Uh, on that project, again, as a cultural piece to do with great facilities, great leadership on the part of the, of the, of the executive teams, et cetera, and stability.

It was the same ex executive team throughout that whole project, which is quite unusual.

Allen Hall: No.

Dermot Kerrigan: Yeah. [00:13:00] Um, so yeah, it, it, it seems to work, you know, uh, always in safety that the, the, the, the tricky thing is trying to prove something works because it hasn’t happened. You know?

Allen Hall: Right, right. Uh, prove the negative.

Dermot Kerrigan: Yeah. Um,

Allen Hall: but in safety, that’s what you want to have happen. You, you do know, not want an outcome.

Dermot Kerrigan: No, absolutely not.

Allen Hall: No reports, nothing.

Dermot Kerrigan: No. So, you know, you have to give credit to, to organizations. Organizations like SSE. Oh, absolutely. And projects like Tideway and Sted, uh, on their horn projects. Who, who have gone down this, frankly, very left field, uh, route.

We we’re, you know, it is only in the last 10 years that we’ve been doing this kind of thing, and it hasn’t, I mean, you know, Tideway certainly is now showing some results. Sure. But, you know, it’s, it’s, it, it wasn’t by any means a proven way of, of, of dealing with safety. So

Mark Patterson: I don’t think you could ever prove it.

Dermot Kerrigan: No.

Mark Patterson: And actually there’s, there’s something [00:14:00]fundamentally of. It, it kind of puts a stamp on the culture that you want, either you talked about the projects in SSE, we’ve, we’ve done it for all of our operational activities, so we’ve had about 9,000 people through it for SSE and so far about 2000 contract partners.

Um, we’re absolutely shifting our focus now. We’ve got probably 80% of our operational teams have been through this in each one of our businesses, and, uh, we. We probably are kind of closing the gaps at the moment, so I was in Ireland with. I here guys last week, um, doing a, a mobile session because logistically it was kind of hard to come to Perth or to one of the other centers, but we’re, we’re gradually getting up to that 80%, uh, for SSE colleagues and our focus is shifting a bit more to contract partners and making sure they get through.

And look, they are super positive about this. Some of them have done that themselves and worked with a TT in the past, so they’re. Really keen to, to use the center that we have [00:15:00] here in Perth, uh, for their activities. So when, when they’re working with us, we kind of work together to, to make that happen. Um, but they can book that separately with you guys.

Yeah. Uh, in, in the, uh, Fastly Center too.

Allen Hall: I think we should describe the room that we’re in right now and why this was built. This is one of three different scenes that, that each of the. Students will go through to put some realism to the scenario and the scenario, uh, a worker gets killed. This is that worker’s home?

Dermot Kerrigan: Yeah. So each of the spaces that we have here that, that they denote antecedents or consequences, and this is very much consequences. Um, so the, the, the participants will be shown in here, uh, as they go around the center, uh, and there’s a scene that takes place where they meet the grown up daughter of the young fella who’s been right, who’s been, who’s been tragically killed.

Uh, and she basically asks him, uh, asks [00:16:00] them what happened. And kind of crucially this as a subtext, why didn’t you do something about it?

Allen Hall: Mm-hmm.

Dermot Kerrigan: Because you were there,

Allen Hall: you saw it, why it was played out in front of you. You saw, you

Dermot Kerrigan: saw what happened. You saw this guy who was obviously fast asleep in the canteen.

He was exhausted. Probably not fit for work. Um, and yet being instructed to go back out there and finish the job, um, with all the tragic consequences that happen,

Allen Hall: right?

Dermot Kerrigan: But it’s important to say, as Mark says, that. It’s not all doom and gloom. The first part of the day is all about showing them consequences.

Allen Hall: Sure. It’s

Dermot Kerrigan: saying it’s a,

Allen Hall: it’s a Greek tragedy

Dermot Kerrigan: in

Allen Hall: some

Dermot Kerrigan: ways, but then saying this doesn’t have to happen. If you just very subtly influence other people’s behavior, it’s

Allen Hall: slight

Dermot Kerrigan: by thinking about how you behave and sure adapting your behavior accordingly, you can completely change the outcome. Uh, so long as I can figure out where you are coming from and where that behavior is coming from, I might be able to influence it,

Allen Hall: right.

Dermot Kerrigan: And if I can, then I can stop that [00:17:00] hap from happening. And sure enough, at the end of the day, um, the last scene is that the, the, the daughter that we see in here growing up and then going back into this tragic, uh, ending, uh. She’s with her dad, then it turned out he was the one behind the camera all along.

So he’s 45 years old, she’s just passed the driving test and nobody got her 21 years ago. You know,

Mark Patterson: I think there, there is, there’s a journey that you’ve gotta take people through to get to believe that. And kind of part of that journey is as, as we look around this room, um, no matter who it is, and we’ve talked to a lot of people, they’ll be looking at things in this room and think, well, yeah, I’ve got a cup like that.

And yes. Yeah. When my kids were, we, we had. That play toy for the kids. Yes. So there is something that immediately hooks people and children hook

Allen Hall: people.

Mark Patterson: Absolutely. And

Allen Hall: yes,

Mark Patterson: they get to see that and understand that this is, this is, this is, could be a real thing. And also in the work site, uh, view, there’s kind of a work site, there’s a kind of a boardroom type thing [00:18:00] and you can actually see, yeah, that’s what it kind of feels like.

The work sites a little bit. You know, there’s scuffs in the, on the line, on the floor because that’s what happens in work sites and there’s a sense of realism for all of this, uh, is really important.

Allen Hall: The realism is all the way down to the outfits that everybody’s worn, so they’re not clean safety gear.

It’s. Dirty, worn safety gear, which is what it should be. ’cause if you’re working, that’s what it should look like. And it feels immediately real that the, the whole stage is set in a, in the canteen, I’ll call it, I don’t know, what do you call the welfare area? Yeah. Okay.

Dermot Kerrigan: Yeah.

Allen Hall: Okay. Uh, wanna use the right language here.

But, uh, in the states we call it a, a break room. Uh, so you’re sitting in the break room just minding your own business and boom. An actor walks in, in full safety gear, uh, speaking Scottish very quickly, foreign American. But it’s real.

Mark Patterson: I think

Allen Hall: it feels real because you, you, I’ve been in those situations, I’ve seen that that break the,

Mark Patterson: the language is real and, uh, [00:19:00] perhaps not all, uh, completely podcast suitable.

Um, but when you look at it, the feedback we’ve got from, from people who are closer to the tools and at all levels, in fact is, yeah. This feels real. It’s a credible scenario and uh, you get people who. I do not want to be in a safety training for an entire day. Um, and they’re saying arms folded at the start of the day and within a very short period of time, they are absolutely watching what the heck’s going on here.

Yes. To understand what’s happening, what’s going on. I don’t understand. And actually it’s exactly as you say, those subtle things that you, not just giving people that experience, but the subtle things you can nudge people on to. There’s some great examples of how do you nudge people, how do you give feedback?

And we had some real examples where people have come back to us and said even things to do with their home life. We were down in London one day, um, and I was sitting in on the training and one of the guys said, God, you’ve just taught me something about how I can give feedback to people in a really impactful [00:20:00] way.

So you, so you explain the behavior you see, which is just the truth of what the behavior is. This is what I saw you do, this is what happened, but actually the impact that that has. How that individual feels about it. And the example that they used was, it was something to do with their son and how their son was behaving and interacting.

And he said, do you know what? I’ve struggled to get my son to toe the line to, to look after his mom in the right way. I’m gonna stop on the way home and I’m gonna have a conversation with him. And I think if I. Keep yourself cool and calm and go through those steps. I think I can have a completely different conversation.

And that was a great example. Nothing to do with work, but it made a big difference to that guy. But all those work conversations where you could just subtly change your tone. Wind yourself back, stay cool and calm and do something slightly different. And I think that those, those things absolutely make a difference,

Allen Hall: which is hard to do in the moment.

I think that’s what the a TT training does make you think of the re the first reaction, [00:21:00] which is the impulsive reaction. We gotta get this job done. This has gotta be done. Now I don’t have the right safety gear. We’ll, we’ll just do it anyway to, alright, slow. Just take a breather for a second. Think about what the consequences of this is.

And is it worth it at the end of the day? Is it worth it? And I think that’s the, the reaction you want to draw out of people. But it’s hard to do that in a video presentation or

Dermot Kerrigan: Yeah.

Allen Hall: Those things just

Dermot Kerrigan: don’t need to practice.

Allen Hall: Yeah. It doesn’t stick in your brain.

Dermot Kerrigan: You need to give it a go And to see, right.

To see how to see it happen. And, and the actors are very good. They’re good if they, you know. What, whatever you give them, they will react to.

Mark Patterson: They do. That’s one of the really powerful things. You’ve got the incident itself, then you’ve got the UNP of what happened, and then you’ve got specific, uh, tools and techniques and what’s really good is.

Even people who are not wildly enthusiastic at the start of the day of getting, being interactive in, in, in a session, they do throw themselves into it ’cause they recognize they’ve been through [00:22:00] something. It’s a common sense of community in the room.

Dermot Kerrigan: Right.

Mark Patterson: And they have a bit of fun with it. And it is fun.

Yeah. You know, people say they enjoy the day. Um, they, they, they recognize that it’s challenged them a little bit and they kinda like that, but they also get the opportunity to test themselves. And that testing is really important in terms of, sure. Well, how do you challenge somebody you don’t know and you just walking past and you see something?

How do you have that conversation in a way that just gets to that adult To adult communication? Yeah. And actually gets the results that you need. And being high handed about it and saying, well, those are the rules, or, I’m really important, just do it. That doesn’t give us a sustained improvement.

Dermot Kerrigan: PE people are frightened of failure, you know?

Sure. They’re frightened of getting things wrong, so give ’em a space where they, where actually just fall flat in your face. Come back up again and try again. You know, give it a go. And, because no one’s, this is a safe space, you know, unlike in the real world,

Allen Hall: right?

Dermot Kerrigan: This is as near to the real world as you want to get.

It’s pretty real. It’s safe, you know, uh, it’s that Samuel Beckett thing, you know, fail again, [00:23:00] fail better,

Allen Hall: right?

Mark Patterson: But there’s, there’s a really good thing actually because people, when they practice that they realize. Yeah, it’s not straightforward going up and having a conversation with somebody about something they’re doing that could be done better.

And actually that helps in a way because it probably makes people a little bit more generous when somebody challenges them on how they’re approaching something. Even if somebody challenges you in a bit of a cat handed way, um, then you can just probably take a breath and think this. This, this guy’s probably just trying to have a conversation with me,

Allen Hall: right.

Mark Patterson: So that I get home to my family.

Allen Hall: Right.

Mark Patterson: It’s hard to get annoyed when you get that mindset. Mindset

Allen Hall: someone’s looking after you just a little bit. Yeah. It does feel nice.

Mark Patterson: And, and even if they’re not doing it in the best way, you need to be generous with it. So there’s, there’s good learnings actually from both sides of the, the, the interaction.

Allen Hall: So what’s next for SSE and at t? You’ve put so many people through this project in, in the program and it has. Drawn great results.

Mark Patterson: Yeah.

Allen Hall: [00:24:00] How do you, what do you think of next?

Mark Patterson: So what’s next? Yeah, I guess, uh, probably the best is next to come. Next to come. We, I think there’s a lot more that we can do with this.

So part of what we’ve done here is establish with a big community of people, a common sense of what we’re doing. And I think we’ve got an opportunity to continue with that. We’ve got, um, fortunate to be in a position where we’ve got a good level of growth in the business.

Allen Hall: Yes,

Mark Patterson: we do. Um, there’s a lot going on and so there’s always a flow of new people into an organization, and if people, you know, the theory of this stuff better than I do, would say that you need to maintain a, a sense of community that’s kind of more than 80%.

If you want a certain group of people to act in a certain way, you need about 80% of the people plus to act in that way, and then it’ll sustain. But if it starts. To drift so that only 20% of people are acting a certain way, then that is gonna ex extinguish that elements of the culture. So we need to keep topping up our Sure, okay.

Our, our [00:25:00] immersive training with people, and we’re also then thinking about the contract partners that we have and also leaving a bit of a legacy. For the communities in Scotland, because we’ve got a center that we’re gonna be using a little bit less because we’ve fortunate to get the bulk of our people in SSE through, uh, we’re working with contract partners.

They probably want to use it for. For their own purposes and also other community groups. So we’ve had all kinds of people from all these different companies here. We’ve had the Scottish first Minister here, we’ve had loads of people who’ve been really quite interested to see what we’re doing. And as a result of that, they’ve started to, uh, to, to step their way through doing something different themselves.

So,

Allen Hall: so that may change the, the future of at t also. And in terms of the slight approach, the scenarios they’re in. The culture changes, right? Yeah. Everybody changes. You don’t wanna be stuck in time.

Dermot Kerrigan: No, absolutely.

Allen Hall: That’s one thing at t is not,

Dermot Kerrigan: no, it’s not

Allen Hall: stuck in time.

Dermot Kerrigan: But, uh, I mean, you know, we first started out with the centers, uh, accommodating project.

Yeah. So this would [00:26:00] be an induction space. You might have guys who were gonna work on a project for two weeks, other guys who were gonna work on it for six months. They wanted to put them through the same experience. Mm. So that when they weren’t on site. That they could say, refer back to the, the, the, the induction and say, well, why ask me to do that?

You know, we, we, we both have that experience, so I’m gonna challenge you and you’re gonna accept challenge, et cetera. So it was always gonna be a short, sharp shock. But actually, if you’re working with an organization, you don’t necessarily have to take that approach. You could put people through a little bit of, of, of, of the training, give ’em a chance to practice, give ’em a chance to reflect, and then go on to the next stage.

Um. So it, it becomes more of a, a journey rather than a single hard, a single event experience. Yeah. You don’t learn to drive in a day really, do you? You know, you have to, well, I do transfer it to your right brain and practice, you know?

Allen Hall: Right. The more times you see an experience that the more it’s memorable and especially with the, the training on how to work with others.[00:27:00]

A refresh of that is always good.

Dermot Kerrigan: Yeah.

Allen Hall: Pressure changes people and I think it’s always time to reflect and go back to what the culture is of SSE That’s important. So this, this has been fantastic and I, I have to. Thank SSC and a TT for allowing us to be here today. It was quite the journey to get here, but it’s been really enlightening.

Uh, and I, I think we’ve been an advocate of a TT and the training techniques that SSC uses. For well over a year. And everybody we run into, and in organizations, particularly in win, we say, you, you gotta call a TT, you gotta reach out because they’re doing things right. They’re gonna change your safety culture, they’re gonna change the way you work as an organization.

That takes time. That message takes time. But I do think they need to be reaching out and dermo. How do they do that? How do, how do they reach att?

Dermot Kerrigan: Uh, they contact me or they contact att. So info at Active Trading Team, us.

Allen Hall: Us. [00:28:00] There you go.

Dermot Kerrigan: or.co uk. There you go. If you’re on the other side of the pond. Yeah.

Allen Hall: Yes. And Mark, because you just established such a successful safety program, I’m sure people want to reach out and ask, and hopefully a lot of our US and Australian and Canadian to listen to this podcast. We’ll reach out and, and talk to you about how, what you have set up here, how do they get ahold of you?

Mark Patterson: I’ll give you a link that you can access in the podcast, if that. Great. And uh, look. The, the risk of putting yourself out there and talking about this sort of thing is you sometimes give the impression you’ve got everything sorted and we certainly don’t in SSE. And if the second you think you’ve got everything nailed in terms of safety in your approach, then, then you don’t.

Um, so we’ve got a lot left to do. Um, but I think this particular thing has made a difference to our colleagues and, and contract partners and just getting them home safe.

Allen Hall: Yes. Yes, so thank you. Just both of you. Mark Dermott, thank you so much for being on the podcast. We appreciate both [00:29:00] of you and yeah, I’d love to attend this again, this is.

Excellent, excellent training. Thanks, Alan. Thanks.

-

Greenhouse Gases6 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change6 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits