Top Green Hydrogen Projects Pushing the Clean Energy Frontier

Green hydrogen, produced by splitting water using renewable energy like solar or wind, is rapidly emerging as a crucial weapon in the fight against climate change.

Across the globe, ambitious green hydrogen projects are rewriting the narrative of clean energy. From Saudi Arabia’s NEOM, aiming to be the world’s largest producer, to Australia’s Western Green Energy Hub fostering a 50 GW renewable energy powerhouse, these initiatives push the boundaries of technology and collaboration.

These projects aren’t just about generating clean fuel; they’re creating entire ecosystems, from harnessing diverse renewable resources like solar, wind, and even seawater, to building hydrogen production, storage, and utilization infrastructure. This not only promises to decarbonize various sectors, but also drive economic growth, create jobs, and pave the way for a cleaner future for everyone. With innovation and commitment paving the path, green hydrogen stands poised to reshape our energy landscape and lead us towards a more sustainable world.

Here are some of the top green hydrogen projects around the world, pushing the boundaries of clean energy production and paving the way for a sustainable future:

1. NEOM Green Hydrogen Project, Saudi Arabia

The NEOM Green Hydrogen Project is expected to be a major driver of the hydrogen economy in Saudi Arabia and the region.

- Visionary Ambitions: This mega-project aims to become the world’s largest producer of green hydrogen, with a target of 1.2 million tons per year by 2026.

- Harnessing Sunshine and Seawater: Utilizing advanced electrolysis technology, the project will split seawater using abundant solar and wind energy.

- Green Fuel for the Future: The produced hydrogen will cater to domestic needs and be exported, powering various sectors like transportation and heavy industries.

Data:

- Location: NEOM, Saudi Arabia

- Installed Capacity: 1.2 million tons per year by 2026

- Technology: Electrolysis powered by solar and wind energy

- Applications: Domestic energy needs, export for transportation and heavy industries

NEOM Green Hydrogen Project Data Table

| Feature | Information |

|---|---|

| Location | NEOM, Saudi Arabia |

| Target Capacity | 1.2 million tons of green hydrogen per year by 2026 |

| Technology | Electrolysis powered by solar and wind energy |

| Water Source | Seawater |

| Applications | Domestic energy needs, export for transportation and heavy industries |

| Current Status | Under development |

| Expected Completion Date | Phase 1 by 2025, full capacity by 2026 |

| Developers | ACWA Power, Air Products, NEOM |

| Estimated Investment | US$5 billion |

| Environmental Benefits | Reduction of greenhouse gas emissions, air pollution, and reliance on fossil fuels |

| Economic Benefits | Creation of jobs, local economic development, diversification of Saudi Arabia’s energy mix |

Additional Notes:

- The project is one of many large-scale green hydrogen projects planned or underway around the world.

- Green hydrogen is seen as a promising clean fuel that can be used in a variety of sectors, including transportation, power generation, and industrial processes.

2. Western Green Energy Hub (WGEH), Australia

The project is expected to make a significant contribution to Australia’s renewable energy targets and decarbonization goals.

- Renewable Powerhouse: This ambitious project plans to create a 50 GW renewable energy hub in Western Australia, dedicated to green hydrogen production.

- Scaling Up Clean Energy: By 2030, WGEH expects to produce 5 million tons of green hydrogen annually, making it a global leader in the field.

- Driving the Hydrogen Economy: The project will not only generate clean fuel but also create an entire ecosystem around hydrogen production, storage, and utilization.

Data:

- Location: Western Australia

- Installed Capacity: 50 GW renewable energy hub by 2030

- Annual Production: 5 million tons of green hydrogen

- Applications: Green hydrogen production, storage, and utilization ecosystem

Western Green Energy Hub (WGEH), Australia Statistics Table

| Feature | Information |

|---|---|

| Location | Goldfields-Esperance region, Western Australia |

| Project Type | Renewable energy hub focused on green hydrogen production |

| Total Planned Capacity | 50 Gigawatts (GW) by 2030 |

| Phase 1 Capacity | 15 GW by 2028 |

| Expected Green Hydrogen Production | Up to 3.5 million tonnes per year by 2030 |

| Technology Utilized | Combination of solar, wind, and potentially other renewable energy sources |

| Electrolysis Technology | High-efficiency electrolysis for green hydrogen production |

| Water Source | Desalinated seawater or renewable freshwater (depending on final feasibility studies) |

| Land Area | Approximately 15,000 square kilometers |

| Estimated Investment | AUD$100 billion over the project lifetime |

| Developers | Consortium including Intercontinental Energy, CWP Global, and Mirning Green Energy Limited |

| Indigenous Involvement | Mirning Green Energy Limited, a wholly-owned subsidiary of the Mirning Traditional Lands Aboriginal Corporation, holds a meaningful carried equity stake and a permanent seat on the project’s consortium board. |

| Environmental Benefits | Reduction of greenhouse gas emissions, air pollution, and reliance on fossil fuels |

| Economic Benefits | Creation of thousands of jobs, local economic development, diversification of Australia’s energy mix |

| Project Status | Under development, awaiting final approvals and securing investors |

Additional Notes:

- The WGEH is one of the most ambitious green hydrogen projects in the world.

- The WGEH’s focus on local stakeholder engagement and indigenous participation are key aspects of the project.

- The final details of the project, such as water source and specific technologies utilized, may be subject to change as feasibility studies are completed.

3. Tsau Khaeb Project, Namibia

The Tsau Khaeb Project is one of the largest green hydrogen projects in Africa and has the potential to significantly contribute to Namibia’s economic development and environmental goals.

- African Green Hydrogen Pioneer: This 3 GW project, developed by HYPHEN Hydrogen Energy, will be one of the largest green hydrogen producers in Africa.

- Renewable Energy Oasis: Utilizing Namibia’s vast solar potential, the project will generate 300,000 tons of green hydrogen annually for export.

- Boosting Local Development: Tsau Khaeb will not only contribute to clean energy but also create jobs and stimulate economic growth in Namibia.

Data:

- Location: Namibia

- Installed Capacity: 3 GW

- Annual Production: 300,000 tons of green hydrogen

- Applications: Export for international markets, local job creation and economic growth

Tsau Khaeb Project, Namibia Statistics Table

| Feature | Information | |

|---|---|---|

| Location | Tsau Khaeb National Park, ![Map of Tsau Khaeb National Park, Namibia] southern Namibia | |

| Project Type | 5 GW green hydrogen production facility | |

| Annual Production Capacity | 3 million tonnes of green hydrogen | |

| Technology Utilized | Advanced solar and wind electrolysis using renewable energy | |

| Water Source | Desalinated seawater and treated wastewater | |

| Export Markets | Primarily Europe and Asian countries | |

| Land Area | Approximately 5,000 square kilometers | |

| Estimated Investment | USD 8.5 billion | |

| Developers | Consortium including Hywind Namibia, ENERTRAG, and CMB.TECH | |

| Local Community Involvement | Partnerships with local communities for skills development and project benefits sharing | |

| Environmental Benefits | Reduction of greenhouse gas emissions, air pollution, and reliance on fossil fuels for export markets | |

| Economic Benefits | Creation of thousands of jobs during construction and operation, local economic development, and diversification of Namibia’s energy mix | |

| Project Status | Early development stage, seeking final approvals and investors |

Additional Notes:

- The project is located in a pristine area and aims to implement strict environmental safeguards to minimize its impact on the local ecosystem.

- The Tsau Khaeb Project prioritizes local community involvement and skills development, aiming to create lasting benefits for the people of Namibia.

- If successful, the project could be a model for other large-scale green hydrogen developments in Africa and beyond.

4. Yara Birkeland, Norway

The Yara Birkeland is a prototype vessel, and the project is considered a crucial demonstration of the feasibility and benefits of green hydrogen-powered shipping.

- The World’s First Emission-Free Cargo Ship: This groundbreaking project has developed the world’s first fully electric container ship, powered by green hydrogen.

- Zero-Emission Shipping: Yara Birkeland eliminates harmful emissions from seaborne transport, paving the way for a cleaner maritime industry.

- Scaling Up the Technology: The project serves as a crucial demonstration of the viability of green hydrogen in powering marine vessels, with plans to build a fleet of similar ships in the future.

Data:

- Location: Norway

- Technology: Fully electric container ship powered by green hydrogen

- Benefits: Zero-emission shipping, cleaner maritime industry

- Future: Plans to build a fleet of similar ships

Yara Birkeland, Norway Statistics Table

| Feature | Information | |

|---|---|---|

| Ship Type | Fully electric container ship | |

| Cargo Capacity | 120 TEU (twenty-foot equivalent units) | |

| Propulsion System | Two 2.3 MW electric motors powered by 465 kW battery packs | |

| Fuel Source | Green hydrogen produced from renewable energy | |

| Emissions Reduction | Eliminates 70,000 tons of CO2 emissions annually compared to diesel trucks | |

| Range | Approximately 125 nautical miles (232 km) on a single hydrogen refueling | |

| Route | Operates between Porsgrunn and Herøya in Norway | |

| Operator | Yara International | |

| Shipyard | Vard Group | |

| Launched | 2017 | |

| Delivered | 2021 | |

| Project Cost | Approximately €25 million | |

| Significance | First fully electric container ship in the world, pioneering zero-emission shipping technology |

Additional Notes:

- The success of the Yara Birkeland is expected to pave the way for the development of a fleet of similar vessels in the future, potentially revolutionizing the maritime industry.

- The project has received international recognition for its innovation and environmental leadership.

5. HyDeal Australia Project

The HyDeal Australia Project is one of the largest green hydrogen export projects in the world

- Harnessing Wind Power for Clean Hydrogen: This 1.5 GW project will utilize abundant wind resources in Western Australia to produce 445,000 tons of green hydrogen annually.

- Exporting Clean Fuel to Asia: The produced hydrogen will be primarily exported to Japan and South Korea, contributing to decarbonization efforts in these countries.

- International Collaboration: HyDeal Australia showcases successful international collaboration in advancing green hydrogen production and utilization.

Data:

- Location: Western Australia

- Installed Capacity: 1.5 GW

- Annual Production: 445,000 tons of green hydrogen

- Applications: Export to Japan and South Korea for decarbonization efforts

HyDeal Australia Project Statistics Table

| Feature | Information | |

|---|---|---|

| Location | Pilbara region, Western Australia | |

| Project Type | 1.5 GW green hydrogen production facility | |

| Annual Production Capacity | 445,000 tonnes of green hydrogen | |

| Technology Utilized | Advanced wind electrolysis using renewable energy | |

| Water Source | Desalinated seawater or treated wastewater | |

| Export Markets | Primarily Japan and South Korea | |

| Land Area | Approximately 1,000 square kilometers | |

| Estimated Investment | AUD$5.4 billion | |

| Developers | Consortium including Plug Power, Fortescue Metals Group, and CWP Renewables | |

| Indigenous Involvement | Pilbara Traditional Lands Aboriginal Corporation holds a 10% stake in the project | |

| Environmental Benefits | Reduction of greenhouse gas emissions, air pollution, and reliance on fossil fuels for export markets | |

| Economic Benefits | Creation of hundreds of jobs during construction and operation, local economic development, and diversification of Australia’s energy mix | |

| Project Status | Under development, seeking final approvals and investors |

Additional Notes:

- The project is expected to play a significant role in decarbonizing the energy sectors of Japan and South Korea, two major trading partners of Australia.

- The HyDeal Australia Project prioritizes local content and indigenous participation, aiming to create lasting economic benefits for the Pilbara region.

- The project is a promising example of international collaboration in advancing green hydrogen production and utilization.

These are just a few examples of the exciting green hydrogen projects shaping the future of clean energy. With continuous advancements in technology and growing global commitment to sustainability, green hydrogen is poised to play a key role in decarbonizing various sectors and creating a cleaner planet for generations to come.

Top Green Hydrogen Projects: Key Takeaway

Across the globe, a green revolution is brewing, and at its heart lie visionary projects harnessing the transformative power of hydrogen.

From NEOM’s sun-drenched shores, destined to become the world’s green hydrogen leader, to Australia’s vast WGEH pulsating with renewable energy, these initiatives rewrite the narrative of clean energy. They’re not mere power plants; they’re ecosystems, weaving together diverse renewable resources like solar, wind, and even seawater, with intricate networks for hydrogen production, storage, and utilization.

This isn’t just about decarbonizing sectors; it’s about reimagining our energy landscape. Jobs flourish in the shadow of towering wind turbines, local economies bloom around electrolysis hubs, and the very air breathes cleaner as dependence on fossil fuels wanes. The Yara Birkeland, a silent titan gliding across Norwegian waters on green hydrogen, epitomizes this promise, while the HyDeal Australia project bridges continents, forging a clean energy future for Asian economies.

This is a symphony of innovation, collaboration, and unwavering commitment to a sustainable future. The top green hydrogen projects are not just engineering marvels; they’re testaments to human ingenuity, painting a vibrant canvas of a world powered by clean, limitless energy. As these projects unfurl their potential, they beckon us to join the chorus, to become active participants in this green revolution, and together, orchestrate a symphony of a cleaner, brighter future for generations to come.

https://www.exaputra.com/2024/01/top-green-hydrogen-projects.html

Renewable Energy

BladeBUG Tackles Serial Blade Defects with Robotics

Weather Guard Lightning Tech

BladeBUG Tackles Serial Blade Defects with Robotics

Chris Cieslak, CEO of BladeBug, joins the show to discuss how their walking robot is making ultrasonic blade inspections faster and more accessible. They cover new horizontal scanning capabilities for lay down yards, blade root inspections for bushing defects, and plans to expand into North America in 2026.

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

Welcome to Uptime Spotlight, shining Light on Wind. Energy’s brightest innovators. This is the Progress Powering Tomorrow.

Allen Hall: Chris, welcome back to the show.

Chris Cieslak: It’s great to be back. Thank you very much for having me on again.

Allen Hall: It’s great to see you in person, and a lot has been happening at Blade Bugs since the last time I saw Blade Bug in person. Yeah, the robot. It looks a lot different and it has really new capabilities.

Chris Cieslak: So we’ve continued to develop our ultrasonic, non-destructive testing capabilities of the blade bug robot.

Um, but what we’ve now added to its capabilities is to do horizontal blade scans as well. So we’re able to do blades that are in lay down yards or blades that have come down for inspections as well as up tower. So we can do up tower, down tower inspections. We’re trying to capture. I guess the opportunity to inspect blades after transportation when they get delivered to site, to look [00:01:00] for any transport damage or anything that might have been missed in the factory inspections.

And then we can do subsequent installation inspections as well to make sure there’s no mishandling damage on those blades. So yeah, we’ve been just refining what we can do with the NDT side of things and improving its capabilities

Joel Saxum: was that need driven from like market response and people say, Hey, we need, we need.

We like the blade blood product. We like what you’re doing, but we need it here. Or do you guys just say like, Hey, this is the next, this is the next thing we can do. Why not?

Chris Cieslak: It was very much market response. We had a lot of inquiries this year from, um, OEMs, blade manufacturers across the board with issues within their blades that need to be inspected on the ground, up the tap, any which way they can.

There there was no, um, rhyme or reason, which was better, but the fact that he wanted to improve the ability of it horizontally has led the. Sort of modifications that you’ve seen and now we’re doing like down tower, right? Blade scans. Yeah. A really fast breed. So

Joel Saxum: I think the, the important thing there is too is that because of the way the robot is built [00:02:00] now, when you see NDT in a factory, it’s this robot rolls along this perfectly flat concrete floor and it does this and it does that.

But the way the robot is built, if a blade is sitting in a chair trailing edge up, or if it’s flap wise, any which way the robot can adapt to, right? And the idea is. We, we looked at it today and kind of the new cage and the new things you have around it with all the different encoders and for the heads and everything is you can collect data however is needed.

If it’s rasterized, if there’s a vector, if there’s a line, if we go down a bond line, if we need to scan a two foot wide path down the middle of the top of the spa cap, we can do all those different things and all kinds of orientations. That’s a fantastic capability.

Chris Cieslak: Yeah, absolutely. And it, that’s again for the market needs.

So we are able to scan maybe a meter wide in one sort of cord wise. Pass of that probe whilst walking in the span-wise direction. So we’re able to do that raster scan at various spacing. So if you’ve got a defect that you wanna find that maximum 20 mil, we’ll just have a 20 mil step [00:03:00] size between each scan.

If you’ve got a bigger tolerance, we can have 50 mil, a hundred mil it, it’s so tuneable and it removes any of the variability that you get from a human to human operator doing that scanning. And this is all about. Repeatable, consistent high quality data that you can then use to make real informed decisions about the state of those blades and act upon it.

So this is not about, um, an alternative to humans. It’s just a better, it’s just an evolution of how humans do it. We can just do it really quick and it’s probably, we, we say it’s like six times faster than a human, but actually we’re 10 times faster. We don’t need to do any of the mapping out of the blade, but it’s all encoded all that data.

We know where the robot is as we walk. That’s all captured. And then you end up with really. Consistent data. It doesn’t matter who’s operating a robot, the robot will have those settings preset and you just walk down the blade, get that data, and then our subject matter experts, they’re offline, you know, they are in their offices, warm, cozy offices, reviewing data from multiple sources of robots.

And it’s about, you know, improving that [00:04:00] efficiency of getting that report out to the customer and letting ’em know what’s wrong with their blades, actually,

Allen Hall: because that’s always been the drawback of, with NDT. Is that I think the engineers have always wanted to go do it. There’s been crush core transportation damage, which is sometimes hard to see.

You can maybe see a little bit of a wobble on the blade service, but you’re not sure what’s underneath. Bond line’s always an issue for engineering, but the cost to take a person, fly them out to look at a spot on a blade is really expensive, especially someone who is qualified. Yeah, so the, the difference now with play bug is you can have the technology to do the scan.

Much faster and do a lot of blades, which is what the de market demand is right now to do a lot of blades simultaneously and get the same level of data by the review, by the same expert just sitting somewhere else.

Chris Cieslak: Absolutely.

Joel Saxum: I think that the quality of data is a, it’s something to touch on here because when you send someone out to the field, it’s like if, if, if I go, if I go to the wall here and you go to the wall here and we both take a paintbrush, we paint a little bit [00:05:00] different, you’re probably gonna be better.

You’re gonna be able to reach higher spots than I can.

Allen Hall: This is true.

Joel Saxum: That’s true. It’s the same thing with like an NDT process. Now you’re taking the variability of the technician out of it as well. So the data quality collection at the source, that’s what played bug ducts.

Allen Hall: Yeah,

Joel Saxum: that’s the robotic processes.

That is making sure that if I scan this, whatever it may be, LM 48.7 and I do another one and another one and another one, I’m gonna get a consistent set of quality data and then it’s goes to analysis. We can make real decisions off.

Allen Hall: Well, I, I think in today’s world now, especially with transportation damage and warranties, that they’re trying to pick up a lot of things at two years in that they could have picked up free installation.

Yeah. Or lifting of the blades. That world is changing very rapidly. I think a lot of operators are getting smarter about this, but they haven’t thought about where do we go find the tool.

Speaker: Yeah.

Allen Hall: And, and I know Joel knows that, Hey, it, it’s Chris at Blade Bug. You need to call him and get to the technology.

But I think for a lot of [00:06:00] operators around the world, they haven’t thought about the cost They’re paying the warranty costs, they’re paying the insurance costs they’re paying because they don’t have the set of data. And it’s not tremendously expensive to go do. But now the capability is here. What is the market saying?

Is it, is it coming back to you now and saying, okay, let’s go. We gotta, we gotta mobilize. We need 10 of these blade bugs out here to go, go take a scan. Where, where, where are we at today?

Chris Cieslak: We’ve hads. Validation this year that this is needed. And it’s a case of we just need to be around for when they come back round for that because the, the issues that we’re looking for, you know, it solves the problem of these new big 80 a hundred meter plus blades that have issues, which shouldn’t.

Frankly exist like process manufacturer issues, but they are there. They need to be investigated. If you’re an asset only, you wanna know that. Do I have a blade that’s likely to fail compared to one which is, which is okay? And sort of focus on that and not essentially remove any uncertainty or worry that you have about your assets.

’cause you can see other [00:07:00] turbine blades falling. Um, so we are trying to solve that problem. But at the same time, end of warranty claims, if you’re gonna be taken over these blades and doing the maintenance yourself, you wanna know that what you are being given. It hasn’t gotten any nasties lurking inside that’s gonna bite you.

Joel Saxum: Yeah.

Chris Cieslak: Very expensively in a few years down the line. And so you wanna be able to, you know, tick a box, go, actually these are fine. Well actually these are problems. I, you need to give me some money so I can perform remedial work on these blades. And then you end of life, you know, how hard have they lived?

Can you do an assessment to go, actually you can sweat these assets for longer. So we, we kind of see ourselves being, you know, useful right now for the new blades, but actually throughout the value chain of a life of a blade. People need to start seeing that NDT ultrasonic being one of them. We are working on other forms of NDT as well, but there are ways of using it to just really remove a lot of uncertainty and potential risk for that.

You’re gonna end up paying through the, you know, through the, the roof wall because you’ve underestimated something or you’ve missed something, which you could have captured with a, with a quick inspection.

Joel Saxum: To [00:08:00] me, NDT has been floating around there, but it just hasn’t been as accessible or easy. The knowledge hasn’t been there about it, but the what it can do for an operator.

In de-risking their fleet is amazing. They just need to understand it and know it. But you guys with the robotic technology to me, are bringing NDT to the masses

Chris Cieslak: Yeah.

Joel Saxum: In a way that hasn’t been able to be done, done before

Chris Cieslak: that. And that that’s, we, we are trying to really just be able to roll it out at a way that you’re not limited to those limited experts in the composite NDT world.

So we wanna work with them, with the C-N-C-C-I-C NDTs of this world because they are the expertise in composite. So being able to interpret those, those scams. Is not a quick thing to become proficient at. So we are like, okay, let’s work with these people, but let’s give them the best quality data, consistent data that we possibly can and let’s remove those barriers of those limited people so we can roll it out to the masses.

Yeah, and we are that sort of next level of information where it isn’t just seen as like a nice to have, it’s like an essential to have, but just how [00:09:00] we see it now. It’s not NDT is no longer like, it’s the last thing that we would look at. It should be just part of the drones. It should inspection, be part of the internal crawlers regimes.

Yeah, it’s just part of it. ’cause there isn’t one type of inspection that ticks all the boxes. There isn’t silver bullet of NDT. And so it’s just making sure that you use the right system for the right inspection type. And so it’s complementary to drones, it’s complimentary to the internal drones, uh, crawlers.

It’s just the next level to give you certainty. Remove any, you know, if you see something indicated on a a on a photograph. That doesn’t tell you the true picture of what’s going on with the structure. So this is really about, okay, I’ve got an indication of something there. Let’s find out what that really is.

And then with that information you can go, right, I know a repair schedule is gonna take this long. The downtime of that turbine’s gonna be this long and you can plan it in. ’cause everyone’s already got limited budgets, which I think why NDT hasn’t taken off as it should have done because nobody’s got money for more inspections.

Right. Even though there is a money saving to be had long term, everyone is fighting [00:10:00] fires and you know, they’ve really got a limited inspection budget. Drone prices or drone inspections have come down. It’s sort, sort of rise to the bottom. But with that next value add to really add certainty to what you’re trying to inspect without, you know, you go to do a day repair and it ends up being three months or something like, well

Allen Hall: that’s the lightning,

Joel Saxum: right?

Allen Hall: Yeah. Lightning is the, the one case where every time you start to scarf. The exterior of the blade, you’re not sure how deep that’s going and how expensive it is. Yeah, and it always amazes me when we talk to a customer and they’re started like, well, you know, it’s gonna be a foot wide scarf, and now we’re into 10 meters and now we’re on the inside.

Yeah. And the outside. Why did you not do an NDT? It seems like money well spent Yeah. To do, especially if you have a, a quantity of them. And I think the quantity is a key now because in the US there’s 75,000 turbines worldwide, several hundred thousand turbines. The number of turbines is there. The number of problems is there.

It makes more financial sense today than ever because drone [00:11:00]information has come down on cost. And the internal rovers though expensive has also come down on cost. NDT has also come down where it’s now available to the masses. Yeah. But it has been such a mental barrier. That barrier has to go away. If we’re going going to keep blades in operation for 25, 30 years, I

Joel Saxum: mean, we’re seeing no

Allen Hall: way you can do it

Joel Saxum: otherwise.

We’re seeing serial defects. But the only way that you can inspect and or control them is with NDT now.

Allen Hall: Sure.

Joel Saxum: And if we would’ve been on this years ago, we wouldn’t have so many, what is our term? Blade liberations liberating

Chris Cieslak: blades.

Joel Saxum: Right, right.

Allen Hall: What about blade route? Can the robot get around the blade route and see for the bushings and the insert issues?

Chris Cieslak: Yeah, so the robot can, we can walk circumferentially around that blade route and we can look for issues which are affecting thousands of blades. Especially in North America. Yeah.

Allen Hall: Oh yeah.

Chris Cieslak: So that is an area that is. You know, we are lucky that we’ve got, um, a warehouse full of blade samples or route down to tip, and we were able to sort of calibrate, verify, prove everything in our facility to [00:12:00] then take out to the field because that is just, you know, NDT of bushings is great, whether it’s ultrasonic or whether we’re using like CMS, uh, type systems as well.

But we can really just say, okay, this is the area where the problem is. This needs to be resolved. And then, you know, we go to some of the companies that can resolve those issues with it. And this is really about played by being part of a group of technologies working together to give overall solutions

Allen Hall: because the robot’s not that big.

It could be taken up tower relatively easily, put on the root of the blade, told to walk around it. You gotta scan now, you know. It’s a lot easier than trying to put a technician on ropes out there for sure.

Chris Cieslak: Yeah.

Allen Hall: And the speed up it.

Joel Saxum: So let’s talk about execution then for a second. When that goes to the field from you, someone says, Chris needs some help, what does it look like?

How does it work?

Chris Cieslak: Once we get a call out, um, we’ll do a site assessment. We’ve got all our rams, everything in place. You know, we’ve been on turbines. We know the process of getting out there. We’re all GWO qualified and go to site and do their work. Um, for us, we can [00:13:00] turn up on site, unload the van, the robot is on a blade in less than an hour.

Ready to inspect? Yep. Typically half an hour. You know, if we’ve been on that same turbine a number of times, it’s somewhere just like clockwork. You know, muscle memory comes in, you’ve got all those processes down, um, and then it’s just scanning. Our robot operator just presses a button and we just watch it perform scans.

And as I said, you know, we are not necessarily the NDT experts. We obviously are very mindful of NDT and know what scans look like. But if there’s any issues, we have a styling, we dial in remote to our supplement expert, they can actually remotely take control, change the settings, parameters.

Allen Hall: Wow.

Chris Cieslak: And so they’re virtually present and that’s one of the beauties, you know, you don’t need to have people on site.

You can have our general, um, robot techs to do the work, but you still have that comfort of knowing that the data is being overlooked if need be by those experts.

Joel Saxum: The next level, um, commercial evolution would be being able to lease the kit to someone and or have ISPs do it for [00:14:00] you guys kinda globally, or what is the thought

Chris Cieslak: there?

Absolutely. So. Yeah, so we to, to really roll this out, we just wanna have people operate in the robots as if it’s like a drone. So drone inspection companies are a classic company that we see perfectly aligned with. You’ve got the sky specs of this world, you know, you’ve got drone operator, they do a scan, they can find something, put the robot up there and get that next level of information always straight away and feed that into their systems to give that insight into that customer.

Um, you know, be it an OEM who’s got a small service team, they can all be trained up. You’ve got general turbine technicians. They’ve all got G We working at height. That’s all you need to operate the bay by road, but you don’t need to have the RAA level qualified people, which are in short supply anyway.

Let them do the jobs that we are not gonna solve. They can do the big repairs we are taking away, you know, another problem for them, but giving them insights that make their job easier and more successful by removing any of those surprises when they’re gonna do that work.

Allen Hall: So what’s the plans for 2026 then?

Chris Cieslak: 2026 for us is to pick up where 2025 should have ended. [00:15:00] So we were, we were meant to be in the States. Yeah. On some projects that got postponed until 26. So it’s really, for us North America is, um, what we’re really, as you said, there’s seven, 5,000 turbines there, but there’s also a lot of, um, turbines with known issues that we can help determine which blades are affected.

And that involves blades on the ground, that involves blades, uh, that are flying. So. For us, we wanna get out to the states as soon as possible, so we’re working with some of the OEMs and, and essentially some of the asset owners.

Allen Hall: Chris, it’s so great to meet you in person and talk about the latest that’s happening.

Thank you. With Blade Bug, if people need to get ahold of you or Blade Bug, how do they do that?

Chris Cieslak: I, I would say LinkedIn is probably the best place to find myself and also Blade Bug and contact us, um, through that.

Allen Hall: Alright, great. Thanks Chris for joining us and we will see you at the next. So hopefully in America, come to America sometime.

We’d love to see you there.

Chris Cieslak: Thank you very [00:16:00] much.

Renewable Energy

Understanding the U.S. Constitution

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Here’s their quiz, which should be called the “Constitutional Trivia Quiz.”, whose purpose is obviously to convince Americans of their ignorance.

When I teach, I’m going for understanding of the topic, not the memorization of useless information.

Renewable Energy

Bravery Meets Tragedy: An Unending Story

Here’s a story:

Here’s a story:

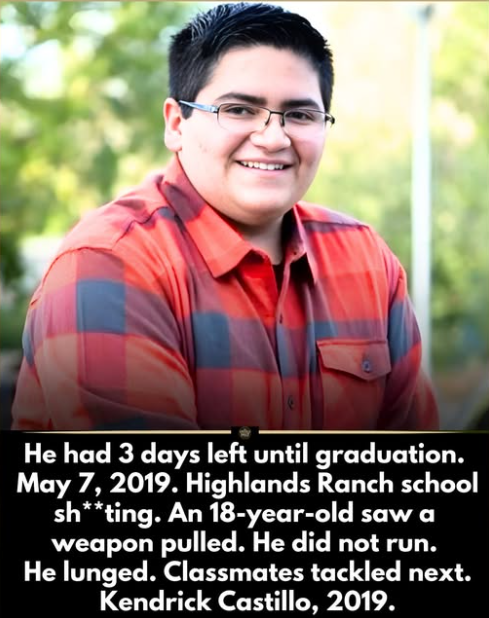

He had 3 days left until graduation.

Kendrick Castillo was 18. A robotics student. College bound. Accepted into an engineering program. The final week of school felt like countdown, not crisis.

Then a weapon appeared inside a classroom.

Students froze.

Kendrick did not.

Witnesses say he moved instantly. He lunged toward the attacker. No hesitation. No calculation.

Two other students followed his lead.

Gunfire erupted.

Kendrick was fatally sh*t.

But his movement changed the room.

Classmates were able to tackle and restrain the attacker until authorities arrived. Investigators later stated that the confrontation disrupted the attack and likely prevented additional casualties.

In seconds, an 18-year-old made a decision most adults pray they never face.

Afterward, the silence was heavier than the noise.

At graduation, his name was called.

His diploma was awarded posthumously. The arena stood in collective applause. An empty seat. A cap and gown without the student inside it.

His robotics teammates remembered him as curious. Competitive. Kind. Someone who solved problems instead of avoiding them.

He had planned to build machines.

Instead, he built a moment.

A moment that classmates say gave them time.

Time to escape.

Two points:

If you can read this without tears welling up in your eyes, you’re a far more stoic person than I.

Since Big Money has made it impossible for the United States to implement the same common-sense gun laws that exist in the rest of the planet, this story will reduplicate itself into perpetuity.

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits