Weather Guard Lightning Tech

US Offshore Wind Halts, Japan Launches First Floating Farm

Allen, Joel, Rosemary, and Yolanda discuss the ongoing federal halt on US offshore wind projects and mounting lawsuits from Equinor, Ørsted, and Dominion Energy. Plus Japan’s Goto floating wind farm begins commercial operation with eight Hitachi turbines on hybrid SPAR-type foundations, and Finnish investigators seize a vessel suspected of severing Baltic Sea cables.

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

The Uptime Wind Energy Podcast brought to you by Strike Tape, protecting thousands of wind turbines from lightning damage worldwide. Visit striketape.com. And now your hosts, Allen Hall, Rosemary Barnes, Joel Saxum and Yolanda Padron. Welcome to the

Allen Hall: Uptime Wind Energy Podcast. I’m your host, Alan Hall. I’m here with Rosie Barnes, Joel Saxum, and Yolanda Padron.

Many things on the docket this week. The, the big one is the five US offshore wind projects that are facing cancellation after the federal halt. And on December 22nd, as we all know, the US Department of Interior ordered construction halted on every offshore wind project in American waters. Uh, the recent given and still given is national security.

Uh, developers see it way differently and they’ve been going to court to try to. Get this issue resolved. Ecuador, Ted and Dominion Energy have all filed lawsuits at this point. EOR says [00:01:00] a 90 day pause, which is what this is right now, will likely mean cancellation of their empire. Project Dominion is losing more than about $5 million a day, and everybody is watching to see what happens.

Orton’s also talking about taking some action here. Uh, there’s a, a lot of moving pieces. Essentially, as it stands right now, a lot of lawsuits, nothing happening in the water, and now talks mostly Ecuador of just completely canceling the project. That will have big implications to US. Electricity along the east coast,

Joel Saxum: right Joel?

Yeah. We need it. Right? So I, I hate to beat a dead horse here because we’ve been talking about this for so long. Um, but. We’ve got energy demand growth, right? We’re sitting at three to 5% year on year demand growth in the United States, uh, which is unprecedented. Since, since, and this is a crazy thing. Since air [00:02:00] conditioning was invented for residential homes, we have not had this much demand for electricity growth.

We’ve been pretty flat for the last 20 years. Uh, so we need it, right? We wanna be the AI data center superpower. We wanna do all this stuff. So we need electrons. Uh, these electrons are literally the quickest thing gonna be on the grid. Uh, up and down that whole eastern seaboard, which is a massive population center, a massive industrial and commercial center of the United States, and now we’re cutting the cord on ’em.

Uh, so it is going to drive prices up for all consumers. That is a reality, right? Um, so we, we hear campaign promises up and down the things about making life more affordable for the. Joe Schmo on the street. Um, this is gonna hurt that big time. We’re already seeing. I think it was, um, we, Alan, you and I talked with some people from PGM not too long ago, and they were saying 20 to 30% increases already early this year.

Allen Hall: Yeah. The, the increases in electricity rates are not being driven by [00:03:00] offshore wind. You see that in the press constantly or in commentary. The reason electricity rates are going up along the east coast is because they’re paying for. The early shutdown of cold fire generation, older generation, uh, petroleum based, uh, dirty, what I’ll call dirty electricity generation, they’re paying to shut those sites down early.

So that’s why your rates are going up. Putting offshore wind into the equation will help lower some of those costs, and onshore wind and solar will help lower those costs. But. The East Coast, especially the Northeast, doesn’t have a lot of that to speak of at the minute. So, uh, Joel, my question is right now, what do you think the likelihood is of the lawsuits that are being filed moving within the next 90 days?

Joel Saxum: I mean, it takes a long time to put anything through any kind of, um, judicial process in the United States, however. There’s enough money, power [00:04:00] in play here that what I see this as is just like the last time we saw an injunction happen like this is, it’s more of a posturing move. I have the power to do this, or we have the power to do this.

It’s, it’s, uh, the, it’s to get power. Over some kind of decision making process. So once, once people come to the table and start talking, I think these things will be let, let back loose. Uh, I don’t, I don’t think it will go all the way to, we need to have lawsuits and stuff. It’ll just be the threat of lawsuits.

There’ll be a little bit of arbitration. They’ll go back to work. Um, the problem that I see. One of the problems, I guess, is if we get to the point where people, companies start saying like, you know what, we can’t do this anymore. Like, we can’t keep having these breaks, these pauses, these, this, you know, if it’s 90 days at $5 million a day, I mean that’s 450 million bucks.

That’s crazy. But that nobody, nobody could absorb that.

Allen Hall: Will they leave the mono piles and transition pieces and some [00:05:00] towers just sitting in the water. That’s what

Joel Saxum: I was gonna say next is. What happens to all of the assets, all of the steel that’s in the water, all the, all the, if there’s cable, it lays if there’s been rock dumps or the companies liable to go pick them up.

I don’t know what the contracts look like, right? I don’t know what the Boem leases say. I don’t know about those kind of things, but most of that stuff is because they go back to the oil field side of things, right? You have a 20 year lease at the end of your 20 year lease. You gotta clean it up. So if you put the things in the water, do they have 20 years to leave ’em out there before they plan on how they’re gonna pull ’em out or they gotta pull ’em out now?

I don’t know.

Allen Hall: Would just bankrupt the LLCs that they formed to create these, uh, wind

Joel Saxum: farms. That’s how the oil field does it bankrupt. The LC move on. You’ve, you’ve more than likely paid a bond when you, you signed that lease and that, but that bond in like in a lot of. Things is not enough. Right. A bond to pull mono piles out would have to be, [00:06:00] I mean, you’re already at billions of dollars there, right?

So, and, and if you look again to the oil and gas world, which is our nearest mirror to what happens here, when you go and decommission an old oil platform in the Gulf of Mexico, you don’t pull the mono piles out. You go down to as close to the sea floor as you can get, and you just cut ’em off with a diamond saw.

So it’s just like a big clamp that goes around. It’s like a big band saw. And you cut the foundations off and then pull the steel back to shore, so that can be done. Um, it’s not cheap.

Allen Hall: You know what I would, what I would do is the model piles are in, the towers are up, and depending on what’s on top of them, whether it’s in the cell or whatever, I would sure as hell put the red flashing lights on top and I would turn those things on and let ’em run just so everybody along the East coast would know that there could be power coming out of these things.

But there’s not. So if you’re gonna look at their red flashy lights, you might as well get some, uh, megawatts out of them. That’s what I would do.

Joel Saxum: You’d have to wonder if the contracts, what, what, what it says in the contracts about. [00:07:00] Uh, utilization of this stuff, right? So if there’s something out there, does the FAA say, if you got a tower out there, it’s gotta have a light on it anyways.

Allen Hall: It has to or a certain height. So where’s the power coming from? I don’t know. Solar panel. Solar panel. That’s what it have to be, right? Yeah. This is ridiculous. But this is the world we live in today.

Speaker 4: Australia’s wind farms are growing fast, but are your operations keeping up? Join us February 17th and 18th at Melbourne’s Pullman on the park for Wind energy o and M Australia 2026, where you’ll connect with the experts solving real problems in maintenance asset management.

And OEM relations. Walk away with practical strategies to cut costs and boost uptime that you can use the moment you’re back on site. Register now at W OM a 2020 six.com. Wind Energy o and m Australia is created by wind professionals for wind professionals. Because this industry needs solutions, not speeches, [00:08:00]

Allen Hall: the dominoes keep falling.

In American offshore wind, last year it was construction halts this year, contract delays. Massachusetts has pushed back the signing of two offshore wind agreements that were supposed to be done. Months ago, ocean Winds and Berroa won their bids in September of 2024. The paperwork is still unsigned more than a year later, a year and a half later.

State officials blame Federal uncertainty. Uh, the new target is June and offshore wind for these delays are really becoming a huge problem, especially if you don’t have an offtake agreements signed, Joel.

Joel Saxum: I don’t see how the, I mean, again, I’m not sitting in those rooms. I’m not a fly on the wall there, but I don’t see how you can have something sitting out there for, it’s just say September 24.

Yeah. Yeah. You’re at 18 months now, right? 17, 18 months without an agreement signed. Why is, why is Massachusetts doing this? What’s, what’s the, what’s the thing there? I mean, you’re an, [00:09:00] you are, uh, an ex Massachusetts, Massachusetts, Ian, is that what it’s called?

Allen Hall: Yeah. I, I think they would like to be able to change the pricing for the offtake is most likely what is happening as, uh, the Trump administration changes the agreements or trying to change the agreements, uh, the price can go up or down.

So maybe the thing to do is to not sign it and wait this out to see what the courts say. Maybe something will happen in your favor. That’s a real shame. Right. Uh, there’s thousands of employees that have been sidelined. Uh, the last number I saw was around 4,000. That seems on the low end.

Joel Saxum: Yeah. I think about, um, the, the vessels too.

Like you’re the, like the Eco Edison that was just built last year. I think it’s upwards of 500 million bucks or something to build that thing down in Louisiana, being sent up there. And you have all these other specialized, uh, vessels coming over from Europe to do all this construction. Um, you know. Of course if they’re coming over from Europe, those are being hot bunked and being paid standby rates, which [00:10:00] is crazy ’cause the standby rates are insane.

Uh, ’cause you still gotta run fuel, you still gotta keep the thing running. You still gotta cook food. You still have all those things that have to happen on that offshore vessel. Uh, but they’re just gonna be sitting out there on DP doing nothing.

Yolanda Padron: You have the vessels, you have people’s jobs. You have.

Regular people who are unrelated to energy at all suffering because of their prices going up for energy and just their cost of living overall going up. All because they don’t look pretty.

Joel Saxum: Yeah. The entire, that entire supply chain is suffering. I mean, Yolanda, you’re, you, you used to work with a company involved in offshore wind.

How many people have, um, you know, have we seen across LinkedIn losing their jobs? Hey, we’re pivoting away from this. I gotta go find something else. And with that. In the United States, if you’re not from the States, you don’t know this, but there’s not that much wind, onshore wind on the East coast. So many of those families had to relocate out there, uproot your family, go out to Massachusetts, New Jersey, [00:11:00] Virginia, wherever, put roots back down and now you’re what?

What happens? You gotta move back.

Yolanda Padron: Good luck to you. Especially, I mean, you know, it’s, it’s a lot of projects, right? So it’s not like you can just move on to the next wind farm. It’s a really unfortunate situation.

Allen Hall: Well, for years the promise of floating wind turbines has dangled just out of reach and the technology works, and the engineers have been saying for quite a while.

We just needed someone to prove it at scale. Well, Japan just did the go-to floating wind farm began commercial operation this past week. Eight turbines on hybrid spar foundations anchored in water is too deep for anything fixed. Bottom, uh, it’s the first. Wind farm of his kind in Japan and signals to the rest of Asia that floating wind is possible.

Now, uh, Rosemary, their turbines that are being used are Hitachi turbines, 2.1 megawatt machines. I don’t know a lot about this hybrid spark [00:12:00] type floater technology, which looks to be relatively new in terms of application. Is this gonna open up a large part of the Japanese shoreline to offshore wind?

Rosemary Barnes: Yeah, I mean, at the first glance it’s like two megawatt turbine turbines. That’s micro, even for onshore these days, that’s a really small turbine. Um, and for offshore, you know, usually when you hear about offshore announcements, it’s like 20 megawatt, 40 megawatt monstrosities. However, I, I think that if you just look at the size of it, then it really underestimates the significance of it, especially for Japan.

Because they, one, don’t have a lot of great space to put turbines on shore or solar power on shore. Um, and two, they don’t have any, any good, um, locations for fixed bottom offshore. So this is not like this floating offshore wind farm. It’s not competing against many onshore um, options at all. For Japan, it’s competing against energy imports.

I’m really happy to see [00:13:00] a proper wind farm. Um, in Japan and they’ll learn a lot from this. And I hope that it goes smoothly and that, you know, the next one can be bigger and better. And then it’s also, you know, Japan traditionally has been a really great manufacturing country and not so much with wind energy, but this could be their chance.

If they’re the country that’s really on scale developing the floating offshore industry, they will necessarily, you know, like just naturally as a byproduct of that, they’re gonna develop manufacturing, at least supporting manufacturing and probably. Some major components and then bring down the cost. You know, the more that, um, these early projects might start out expensive, but get cheaper, fast.

That’s how we hope it’ll go. And then they’ll push out into other areas that could benefit from offshore wind, but um, not at the cost. Somewhere like California, you know, they have the ability to have onshore wind. They’d really like some offshore wind, some floating offshore wind. But it is a hard sell there at the moment because it is so much more expensive.

But if it gets cheaper because, you know, projects like [00:14:00] this help push the price down, then I think it will open things up a lot. So yeah, I am, I’m quite excited to see this project.

Allen Hall: Will it get cheaper at the two to six megawatt range instead of the 15 to 20 megawatt range?

Joel Saxum: That’s what I was gonna comment on.

Like there’s, there’s a, there’s a key here that the general public misses. For a floating offshore wind farm. So if you’re gonna do this cost effectively, that’s why they did it with the 2.1 megawatts ones because with a, with the spar product that they’re using basically. And, and I was sourcing this off at my desk, so here you go,

Rosemary Barnes: Joel.

We need a closed caption version for those listening on the podcast and not watching on YouTube. Joel’s holding like a foam, a foam model of a wind turbine. Looks like it’s got a stubby, stubby holder on the bottom.

Joel Saxum: This is. Turbine. Steel. Steel to a transition piece and then concrete, right? So this is basically a concrete tube like, um, with, with, uh, structural members on the inside of it.

And you can float this thing or you can drag these, you can float ’em key side and then drag ’em out, and [00:15:00] then it just fill ’em halfway or three quarters away with ballast sea seawater. So you just open a valve, fill the thing up to three quarters of the way with seawater, and it sinks it down into the water a little bit.

Water level sits about. Right at the transition piece and then it’s stable. And that’s a hybrid. Spar product is very simple. So to make this a easy demonstrate project, keyside facility is the key, is the big thing. So your Keyside facility, and you need a deep water keyside facility to make this easy. So if you go up to Alan, like you said, a two to six, to eight to 10 to 15 megawatt machine.

You may have to go and take, you may have to barge the spars out and then dump ’em off the spar and then bring the turbines out and put ’em on. That’s not ideal. Right? But if you can do this all keyside, if you can have a crane on shore and you can float the spars and then put the, build the whole turbine, and then drag that out as it sits, that’s a huge cost reduction in the installation operations.

So it, it’s all about how big is the subsea portion of the spar? How? How deep is your [00:16:00] deep water keyside port? To make it efficient to build. Right. So they’re looking at 10 gigawatts of floating offshore wind by 2030. Now it’s 2026. That’s only four years away, so 10 gigawatts. You’re gonna have to scale up the size of the turbines.

It’ll be interesting how they do it, right? Because to me, flipping spars off of a barge is not that hard. That’s how jackets and spars have been installed in the past. Um, for, um, many industries, construction industries, whether it’s oil and gas or just maritime, construction can be done. Not a problem. Um, it’s just not as efficient.

So we’ll see what, we’ll see what they do.

Allen Hall: You would need 5,000 turbines at two megawatts to get to 10 gigawatts, 5,000 turbines. They make 5,000 cars in a day. The, the Japanese manufacturing is really efficient. I wouldn’t put anything by the Japanese capabilities there.

Joel Saxum: The problem with that is the cost of the, the inter array cables and [00:17:00] export cables for 5,000 turbines is extreme.

Allen Hall: We also know that. Some of the best technology has come out of Japan for the last 50 years, and then maybe there’s a solution to it. I, I’m really curious to see where this goes, because it’s a Hitachi turbine. It’s a 2.1 megawatt turbine, as Rosemary’s pointed out. That’s really old technology, but it is inexpensive to manufacture and easy to move around.

Has benefits.

Rosemary Barnes: Yeah. It also means like they, they’re not gonna be surprised with like, you know, all of. When you make a 20 megawatt offshore wind turbine, you’re not only in the offshore environment, you’re also dealing with, you know, all your blade issues from a blade that long and 2.1 megawatt turbine has blades of the size that, you know, just so mature, reliable, robust.

They can at least rule those headaches out of their, um, you know, out of their. Development phase and focus on the, the new stuff.

Joel Saxum: Does anybody know who [00:18:00] makes blades for Hitachi?

Allen Hall: Rosie? Was it lm? I, I, I know we have on a number of Hitachi turbines over time, but I don’t know who makes the blades.

Rosemary Barnes: Yeah, I don’t know.

But I mean, also it’s like, um, it doesn’t mean that they’re locked into 2.1 megawatts for forever, right? So, um, if the economics suggest that it is be beneficial to scale up. Presumably there will be a lot that they have learned from the smaller scale that will be de-risking the, the bigger ones as well.

So, you know, um, it’s, there’s advantages to doing it both ways. It’s probably a slower, more steady progress from starting small and incrementally increasing compared to the, you know, like big, um, fail fast kind of, um, approach where you just do a big, big, huge turbine and just find out everything wrong with it all at once.

Um, but. You know, pros and cons to both.

Allen Hall: Hitachi buys TPI. They got the money. They got the money, and they got the brain power. [00:19:00] Delamination and bottom line. Failures and blades are difficult problems to detect early. These hidden issues can cost you millions in repairs and lost energy production.

C-I-C-N-D-T are specialists to detect these critical flaws before they become expensive burdens. Their non-destructive test technology penetrates deep to blade materials to find voids and cracks. Traditional inspections completely. Miss C-I-C-N-D-T Maps. Every critical defect delivers actionable reports and provides support to get your blades back in service.

So visit cic ndt.com because catching blade problems early will save you millions.

The Baltic Sea has become a chessboard under sea. Cables carry data. Pipelines carry energy as we’ve all seen and someone keeps cutting them. Finnish investigators are now saying a cargo ship dragged its anchor [00:20:00] across the seabed for tens of kilometers before severing a telecommunications cable. On New Year’s Eve, special forces seize the vessel.

Four crew members are detained, but the questions still remain. Who or what is trying to cut cables and pipelines at the bottom of the Baltic Sea.

Joel Saxum: It’s not accidents like it happened on New Year’s Eve and it was, and you drug an anchor for tens of kilometers. That’s on purpose. There’s, there’s no way that this is someone, oh, we forgot to pull the anchor up.

You know how much more throttle you have to put on one of these? Have you seen an anchor for an offshore vessel? They’re the size of a fricking house,

Allen Hall: so they’re investigating it right now. And four, the 14 crew members are under detention. Travel restrictions, we’ll see how long that lasts. Crew includes nationals from of all places, Russia, Georgia, Kazakhstan, and Azerbaijan.

So there is a, a Russian element to this. [00:21:00] I don’t know if you were all watching, I don’t know, a week or two ago when there’s a YouTube video from and oral, which makes undersea. Equipment and defense, uh, related, uh, products. And Palmer Lucky who runs that company basically said, there are microphones all over the bottom of the ocean, all around the world.

Everything is monitored. There’s no way you can drag an anchor for a kilometer without somebody knowing. So I’m a little surprised this took so long to grab hold of, but. Maybe the New Year’s Eve, uh, was a good time to pick because everybody is kind of relaxed and not thinking about a ship, dragging an anchor and breaking telecommunication cables, wind turbines have to be really careful about this.

There, there have to be some sort of monitoring, installation sensors that are going on around the, all the wind power that exists up in that region and all [00:22:00] the way down in, in the North Sea. To prevent this from happening, the sabotage is ridiculous. At this point,

Joel Saxum: yeah. I mean, even, even with mattresses over the export cables, or the inter array cables or, or rock bags or rock dumps or, or burials, these anchors are big enough to, to cut those, to drag and cut ’em like it, it’s just a, it’s a reality.

It’s a risk. But someone needs to be monitoring these things closer if they’re not yet. ’cause you are a hundred percent correct. There’s, so, there’s, there’s private, there’s public sides of the acoustic monitoring, right? So like the United States military monitors, there’s, there’s acoustic monitoring all up and down.

I can’t actually never, I looked into it quite a while ago. There’s a name for the whole system. It’s called the blah, blah, blah, and it monitors our coastline. Like ev, there’s a sensor. Every man, it’s a couple miles. Like all, all around the EEZ of the United States. And that exists everywhere. So like you think like in international waters, guarantee that the United States has got microphones out listening to, [00:23:00] right.

So, but if you’re in the Baltic Sea, it’s a little bit different of an, of a confined space. But you have Estonia, Lithuania, Latvia, all along the southern and eastern coast and the, and Russia. And then you have the Fins, Swedes, Norwegian, Denmark, Germany. Everybody is Poland. Everybody’s monitoring that for sure.

It’s just like a postmortem investigation is, is doable.

Allen Hall: Yolanda, how are they gonna stop this? Should they board the ships, pull the people off and sink them? What is it gonna take for this to end?

Yolanda Padron: I don’t know. In the meantime, I think Joel has a movie going on in his head about how exactly he’s gonna portray this.

Um, yeah, it’s. I mean, I’d say better monitoring, but I, I’m not sure. I guess keep a closer eye on it next time. I mean, I really hope it’s, there’s not a next time, but there seems to be a pattern developing. Right.

Allen Hall: I forgot how many of those happened.

Joel Saxum: Yeah. The maritime, this is a, this is a tough reality about the maritime world.

[00:24:00] ’cause I, I’ve done some work done in Africa and down there it’s specifically the same thing. There’s say there’s a vessel. Okay, so a vessel is flagged from. S Cy Malta, a lot of vessels are flagged Malta or Cyprus, right? Because of the laws. The local laws there that Cyprus flagged vessel may be owned by a company based in, um, Bermuda that’s owned by a company based in Russia that’s owned by a company based in India.

All of these things are this way. There’s shell companies and hidden that you don’t know who owns vessels unless they’re even, even the specific ones. Like if you go to a Maersk vessel. And you’re like, oh, that’s Maersk, they’re Danish. Nope. That thing will be, that thing will be flagged somewhere else, hidden somewhere else.

And it’s all about what port you go to and how much taxes you can hide from, and you’ll never be able to chase down the actual parties that own these vessels and that are responsible you, you, it, it’s so [00:25:00] difficult. You’re literally just going to have to deal with the people on board, and you can try to chase the channels to who owns that boat, but you’ll never find them.

That’s the, that’s the trouble with it.

Allen Hall: It does seem like a Jean Claude Van Dam situation will need to happen pretty soon. Maybe as Steven Segal, something has to happen. It can’t continue to go on it over the next couple of months with as much attention as being paid to international waters and.

Everything that’s happening around the world, you’d think that, uh, ships Defense Department ships from Denmark, Finland, Germany. We will all be watching this really closely UK be watching this and trying to stop these things before they really even happened. Interesting times. That wraps up another episode of the Uptime Wind Energy Podcasts.

If today’s discussion sparked any questions or ideas. We’d love to hear from you. Reach out to us on LinkedIn and don’t forget to subscribe so you never miss an episode. [00:26:00] And if you found value in today’s conversation, please leave us a review. It really helps other wind energy professionals discover the show for Rosie, Yolanda and Joel.

I’m Alan Hall and we’ll catch you next week on the Uptime Wind Energy Podcast.

Renewable Energy

Understanding the U.S. Constitution

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Here’s their quiz, which should be called the “Constitutional Trivia Quiz.”, whose purpose is obviously to convince Americans of their ignorance.

When I teach, I’m going for understanding of the topic, not the memorization of useless information.

Renewable Energy

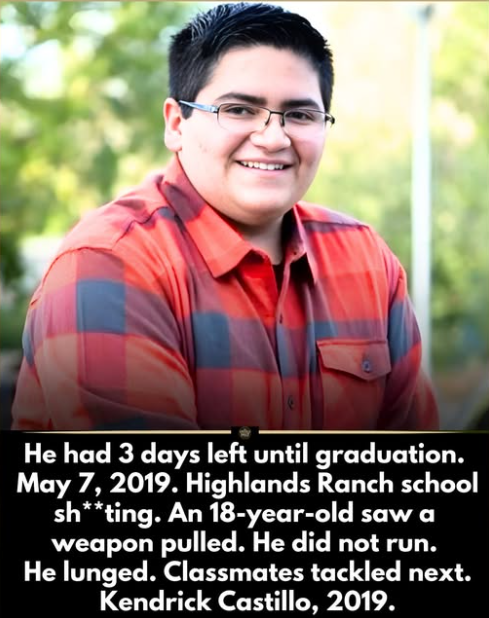

Bravery Meets Tragedy: An Unending Story

Here’s a story:

Here’s a story:

He had 3 days left until graduation.

Kendrick Castillo was 18. A robotics student. College bound. Accepted into an engineering program. The final week of school felt like countdown, not crisis.

Then a weapon appeared inside a classroom.

Students froze.

Kendrick did not.

Witnesses say he moved instantly. He lunged toward the attacker. No hesitation. No calculation.

Two other students followed his lead.

Gunfire erupted.

Kendrick was fatally sh*t.

But his movement changed the room.

Classmates were able to tackle and restrain the attacker until authorities arrived. Investigators later stated that the confrontation disrupted the attack and likely prevented additional casualties.

In seconds, an 18-year-old made a decision most adults pray they never face.

Afterward, the silence was heavier than the noise.

At graduation, his name was called.

His diploma was awarded posthumously. The arena stood in collective applause. An empty seat. A cap and gown without the student inside it.

His robotics teammates remembered him as curious. Competitive. Kind. Someone who solved problems instead of avoiding them.

He had planned to build machines.

Instead, he built a moment.

A moment that classmates say gave them time.

Time to escape.

Two points:

If you can read this without tears welling up in your eyes, you’re a far more stoic person than I.

Since Big Money has made it impossible for the United States to implement the same common-sense gun laws that exist in the rest of the planet, this story will reduplicate itself into perpetuity.

Renewable Energy

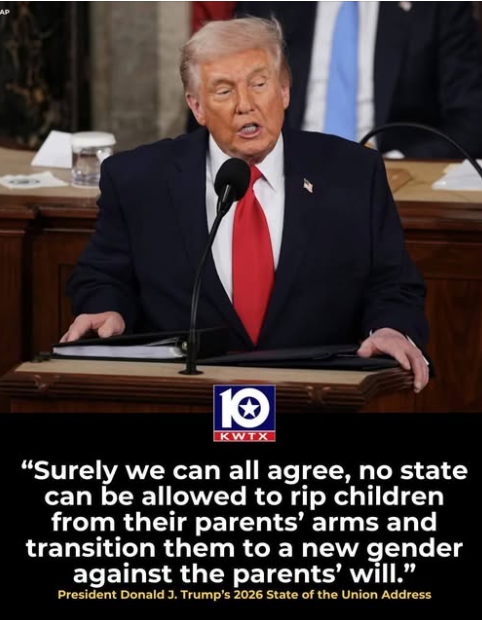

Forced Transgendering of America’s Little Kids

How often does this happen? How about never?

How often does this happen? How about never?

Trump loves to say that little boys go to school and come back home little girls.

He’s the most powerful person in the world for exactly one reason: We’re a nation of morons.

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits