Weather Guard Lightning Tech

EmpathCMS: Fast, Non-Invasive Fault Detection for Wind Turbines

Allen Hall interviews Dr. Howard Penrose, president and founder of MotorDoc LLC, about the groundbreaking EmpathCMS electrical signature analysis system. Dr. Penrose explains how the technology can quickly and non-invasively detect developing faults in wind turbine components like generators, gearboxes, and bearings, helping to optimize maintenance and prevent unplanned downtime.

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Allen Hall: Welcome to the Uptime Wind Energy Podcast. I’m your host, Allen Hall. Our guest today is Dr. Howard Penrose, the president and founder of MotorDoc LLC, and the creator of the groundbreaking EnPath electrical signature analysis system. Dr. Penrose has over 30 years of experience in the field, authoring books, presenting at conferences worldwide, and providing training and consulting services to numerous industries, including wind energy.

The Empath system Dr. Penrose developed is a cutting edge tool for condition monitoring and predictive maintenance of electrical assets like motors, generators, and transformers. By analyzing the unique electrical signatures of equipment, Empath can detect developing faults early, preventing unplanned downtime, optimizing maintenance, and extending equipment life.

Howard, welcome to the program.

Howard Penrose: Thank you very much. And I just have to correct you on one thing. And that’s the Empath system was actually originally developed at Oak Ridge National Labs and is is, construct, is basically built and maintained by Framatome ANP, which is International Nuclear Power Company.

We are their non nuclear distributor and researcher. Large portion of what we do at MotorDoc is research the applications for electrical signature analysis and develop the algorithms.

Allen Hall: So this is, we have a magician here today, so to speak, because the whole thing about wind energy and when you talk to the engineers is the vast majority of them are mechanical engineers.

Drivetrain, blades, right? They know a lot about how the turbine works mechanically. But it is an electrical machine. It’s there to produce electricity. And that means there’s a lot of electric motors and obviously one big generator on the turbine. And that’s the heart of the system. And that’s the part that we really need to work.

What? I think you guys have done is interesting because you’re using the generator to diagnose things that are happening onside the turbine that are not only electrical, but mechanical. You want to explain how that works a little bit?

Howard Penrose: Okay. Well, with vibration analysis, for instance, I will use an accelerometer with a piezoelectric cell or some of the newer technologies that involve etching and certain other things of materials. And you put that on the casing of a machine, and you generate an electrical signal signal in that component, that accelerometer, for instance, or whatever other type of device it is for vibration. So you have to read all the movement of all the components inside the machine through the material.

through that transducer into something else that then translates that data in, either as a rules based system using squiggly lines or a machine learning based system, that kind of thing. Electrical signature analysis is exactly the same thing, except we use the air gap of the machine, whether it’s a generator or a motor or a transformer, as our transducers, the little magnetic field.

In between the components, not the rotor, not the stator. And we gather that information through just straight voltage and current. So the voltage and current comes out we use that and translate it in exactly the same manner we do with vibration. Matter of fact, most vibration analysts will recognize most of the signatures we look at when we’re looking at squiggly lines.

The difference is you have to cross your eyes and stand on your head, but that’s about it.

Allen Hall: So the Empath system, from what I’ve seen online, it measures a couple of voltages and some currents on some wires, which maybe you can describe what you’re actually measuring there.

Howard Penrose: If we’re doing the generator in a wind turbine we’re measuring the voltage and current directly off the stator.

If we’re doing the generator in a wind turbine we’re measuring the voltage and current directly off the stator. So if my transformer is uptower, that data has to come from uptower. If the data, if the transformer is downtower, say in a GE or some of the other machines, I can take that data downtower, which I prefer, to be perfectly honest.

But the idea is you go in you clamp on to three phases of current and three phases of voltage for optimal voltage. analysis. Really, if I’m just analyzing the components, I just need one good phase, right? One, one sinusoidal phase. There’s a lot of things that happen electrically in a machine, in a wind turbine, that are odd as compared to other types of generators.

So we have to work with that. And of course, whether I’m looking at a DFIG I like to call certain designs S FIG. Where I don’t have a feed to the rotor, I just have a switching system, such as in the old Suzlons. Or whether it’s an induction machine or a permanent magnet machine, each one is handled just a little differently, although the signatures are the same.

Allen Hall: So you’re measuring three voltages, three currents. On those signals is the power that’s coming from the generator, basically. But there’s other things on top of that. What electrical signals are on top of that, those power signals?

Howard Penrose: Every movement, every torsional issue, every component from the transformer to the blades.

In a defig even in some of the newer ones and one or two older designs that have the dual planetary gear set. We just added this as a matter of fact, in American clean power, we just add the, into the gearbox playbook, electrical signature analysis is one of the prognostics for the gearbox.

Through the air gap, we get to see. The transformer, we get to see all of the components in the generator that includes the bearings the Y rings and the rotor, which that’s, I think that’s one of the most popular reasons that were used is to define fracturing Y rings, and we’ll see those 14 months out.

And then even wedge issues of either vibrating or missing wedges in certain stator designs. Then we’ll see coupling issues. We’ll see all of the bearings in the gearbox, including the planetary bearings. We will see all the gears in the gearbox. I can’t tell you if it’s broken, cracked, or whatever, but I can tell you that there’s something wrong.

And not only that, I can tell you how much energy is being lost across that defect. And then the main bearings, we’ll even see when we have lubrication issues. One of the most common is when the lubrication is not changed out properly and you get dried grease at the bottom. We’ll read that as an outer race signature.

And then finally, if the blades aren’t aligned right, they don’t, they’re not turned correctly within a couple of degrees. We will see that as a blade pass as the impulse as it, as each blade passes the tower. You’ll see that variation, which can get tricky because certain designs now start to turn the blade a little bit based upon wind gusts and what LIDAR picks up coming at the wind tower.

Just by the way, what we didn’t include is the fact that I’m the chair of standards for ACP for wind. In the United States. So yeah, I have a little idea of what’s going on with the turbines.

Allen Hall: Just a tiny bit. Now, let me give a little, just talk about your background just for a second here, because I think it’s important.

You’re you started in the Navy. You’re from, originally from Canada, right? You came to the States and then you enlisted in the Navy.

Howard Penrose: I’m dual. So I was born in Michigan while my dad was finishing his doctorate at University of Michigan. Then he headed up the fisheries department in St.

John’s, Newfoundland, which makes me an official Newfie. So I joined the Navy. My worst class in A school was electric motors and generators. So I decided it was going to be my best subject. As I was one of the first hundred on board the Theodore Roosevelt, an aircraft carrier, and they said, what do you want to do?

And I said, I want motors. And generators. I was a a conventional electrician, not a nuclear power electrician. So they put me down there and, um, basically being one of the first hundred, I knew everybody. As a matter of fact, the nickname MotorDoc came from the captain of the ship back when I was 19 years old.

He authorized me to become the youngest electric motor repair journeyman in the Navy ever. I think to this day, so you have to sign up for six more years to get it. I didn’t have to I went to motor rewind school. I went to all the theoretical schools. I was enlisted. I got meritoriously advanced through E5 by the time I was 20.

So I spent two years in a chief’s position running a motor repair shop as a journeyman on an aircraft carrier.

Allen Hall: It takes a person like you that has the hand on hands on experience. Plus, a little bit of book knowledge, plus some education, and then have that kind of percolate for several years to go, okay, there is something to electrical signature analysis, and it’s real and to decode it.

I think that’s the hardest part, is decoding what’s there.

Howard Penrose: That, that is exactly the most challenging part, and the part, and the reason why most companies that have attempted to do it have failed is two parts. One is they’re trying to do it with current signature. I’m sorry, but a generator does not produce current.

It produces voltage. Wind is definitely different in that it’s both. There’s times when it acts because of the rotor, it’ll act as a load, times when it’ll act as a generator. And then with all of the controls for VAR correction, voltage correction, things like that. It will do different.

Wild things. The good news is I don’t care. What I do care about is that is that, for those who attempted the technology, not understanding that the technology measures the speed of the magnetic field, not the physical speed of the rotor. I don’t care. So if I’m a vibration analyst, I need feedback as to how fast the rotor is turning.

If I’m doing electrical signature, I need to know how fast the field is turning. Because in order to, in a defig, to get 60 hertz out, my field, if it’s a six pole machine, which a majority are six pole, others are four pole, that’ll be 1200 or 1800 rpm. If it’s a, if it’s a 1200 rpm, it’s going to be running slightly over 1200 rpm, which is why you don’t get exactly 60 hertz, right?

Because if you ran it exactly, then it becomes unstable, so you have to have it, yeah, you have to have it over speed just a little bit. That 1200 RPM motor, I’m just, I’m actually working on 320 turbines before we got on the call. The actual physical speed might hit as high as 1500 RPM, right? But if it did, and I didn’t compensate for that speed, I would have something like 80 Hertz.

Okay. Yeah, coming off, and it would fly all over the place. Then I would have to control it. But one of the, one of the, magical bits about D Fig is the VFD that runs in parallel and feeds the rotor changes either if it falls under that 1, 200 RPM, speeds it up, and if it’s over, slows it down.

One of the things we had discovered because of industrial work in active front end drives, which don’t have a DC bus, we can read through it. A motor that’s running at 35 hertz, on the incoming side, we discovered that all the signatures would be as if it were running at 60 hertz. If it was running as if it was on just a regular power source.

So I applied that to electrical signature. I applied that with electrical signature analysis to wind turbines. And suddenly we were seeing everything.

Allen Hall: So with that, you can see a lot of. noise or frequencies inside of that. You sampled it high enough now that you can start investigating, look inside of that data and you don’t need a lot of data.

You don’t need a lot of time. You don’t have to sit there and analyze data for hours. One set of data. Exactly. And that’s part of the key.

Howard Penrose: Now, this is a rules based system, right? Now we will, if we’re doing continuous monitoring, because we have that capability and we’re working on a capability with some of the OEMs to be able to just take data right from their towers, so we don’t have to have hardware.

to do the analysis. But we need a sample rate of a minimum of 10 kilohertz in order to be able to separate things out. And when we fall below that, the load has to be way up on the machine. The prognostic machines that are at that take data at 7, 500 hertz or less, they have to have wind speeds of at least 10 meters per second to be able to see anything.

We’re seeing it right at cut it. Which is bad. really interesting.

Allen Hall: A lot of machines take data faster than that. 15 kilohertz is what I’m here. Some of them are doing at the minute. So there’s enough data there.

Howard Penrose: But when they do 1500 kilohertz, they had, they only have very small data sets. So they switched that frequency so that we can get a longer data set.

The length of time combined with that that sampling rate is what gives us the resolution. And then because we’re doing 12 kHz, that also gives us a 6 kHz FMAX. That means we can see out to 360, 000 CPM. And most everything on a wind turbine happens under 3, 000 Hz.

Allen Hall: Oh, easy. Yeah. So that’s, and there’s your magic, right?

Now you’ve sampled the data fast enough and long enough to analyze essentially anything that’s happening on the wind turbine. What you’re measuring voltage wise and current wise all that data comes in. You then, I’m going to use some fancy terminology and I promised myself I wasn’t going to do this, but here we go.

They basically take a Fourier transform, right? So you’re looking at it in the frequency spectrum versus the time spectrum. And what that does, you start looking at rotating machines. They’ll start having peaks at certain frequencies based upon the mechanical principles in which they were designed. And then Howard, you come in and go.

That is a bearing, or a gearbox, right?

Howard Penrose: Yeah, and the nice thing is, the formulas are exactly the same. The multipliers for a bearing are the same as what I’d use in vibration. For instance, our technology we have a library of bearings in there with everything preset, so I don’t have to sit there and calculate out all the angles and number of balls and what the cage looks like and all that other crazy stuff that we learned in, in vibration school I just pull it out of a, out of a thing and the same thing that you do for, the multiplier time one RPM is the same multiplier times one Hertz.

Yeah, so we, you get the one time multiplier and you plug it in and you can identify inner race, outer race, ball, or cage. The nice thing about ESA is I don’t get harmonics. I just look at the one time. For that value, just like if I have a rotor related issue, like for instance, somebody asked me, could I detect a failing Y ring with vibration?

I said, absolutely. But you don’t have the bandwidth to do it. It would take too much memory because you would have to look out at four times the four times the. Slot frequency for the rotor, for certain aspects of the failure. Yeah, you’d have to in vibration. You might get lucky and see some pole pass frequency sidebands, which are twice the slip frequency.

But that would be mechanically related versus electrically related. So that’s going to constantly vary.

Allen Hall: So let’s talk about the wiring for a moment. So a wiring is, from simplistic terms, is how a connection internal to a motor that makes the thing spin.

Howard Penrose: Wound rotor generator.

Most wound rotor motors just have a connection made. they don’t have a ring. So in, in defigs, they normally have an actual ring like a hoop, and that goes around, and then they’ll have tabs that connect into it. Some will have direct connections. We’re working on some of those now. But what we discovered first off, we were asked by Chris Petrola from Axiona, and he did a whole presentation on this.

So I dare throw him into the weeds. He’s now with the now and he’ll appreciate it. But he had us go up to Calgary. He called me one day and I happened to be when he called on an overhead crane and a steel bell testing a wound rotor motor for failing slip rims. So we were testing, while everything’s moving, we’re over the pit of steel, a hundred feet up, staring down into molten, whatever, and he calls.

Of course, he called, so I had to answer. And he goes Hey, have you ever detected failing connections in the rotor of a defig generator? And I go, No, but I have a theory . So we go, we went up to Calgary to an to an Axion site, tested 40 turbines. He produced this at awe at the time, now a CP in 2018.

Because we did it in 2016, and then the repair shop out of Quebec went there Dallon, went there and and replaced the Y rings and took pictures of all of them. Now, of the 40 turbines, we detected 20 of them with fractured Y rings, and one, I said, I had a questionable reading. And that turned out to be a partial fracture.

They detected this, and then one year later, after we had detected them, Wind through the machines and pulled out the Y rings and replaced them up tower.

Allen Hall: Okay, so this is the key here. So not only are you able to detect problems in mechanical equipment and electrical equipment, for that matter, early, and diagnose, like, where it is health wise, it can be done so quickly, you can do most of a farm in a day.

Howard Penrose: So from 2017 to present, and wind is only about 20 percent of our work. I personally have been on over 4, 000 turbines collecting data, mostly in the US, some Canada. However, the technology is being used right now heavily in Brazil, Mexico, Canada, US. Asia and just a little bit right now in Europe, definitely in the Middle East too.

Allen Hall: Sure. Anywhere there’s a motor or a generator, you’re there.

Howard Penrose: I’m just talking about wind turbines. As far as the technology goes, it’s being used globally. The Empath system is one of the best kept secrets out there. We’re replacing vibration equipment in the industrial side, all over the place.

Monday, I’m dropping off. enough to for Reynolds aluminum to finish replacing all their vibration equipment with over 400 of our systems.

Allen Hall: Okay. See, this is where I first ran across you. I was on a wind site talking to a site manager. And I was saying, Hey, what’s cool. What’s the cool thing you’ve seen?

And the response back was, have you seen MotorDoc? Those, that equipment came in and they diagnosed every motor generator problem, gearbox problem, bearing problem. We had on each of the turbines and a couple of minutes, literally a couple of minutes, and we started to dig. We thought okay. Maybe? So we dug into them and they were 100 percent right.

Howard Penrose: I like hearing 100%. I usually tell people 85 to 90%. Even though the EPRI study that was done, looking at the technology and Empath was top. We were seen as well over 90. Closer to 95%.

Allen Hall: I think if you guys is one of the, I don’t know, one of the best kept secret, cause you’re not a secret. You’re out there doing tremendous work and OEMs know of you, operators, some operators know you very well.

Howard Penrose: OEMs, Almost all of the OEMs use us, meaning have, they have our equipment but we don’t put the names of our customers on our website to brag. We’ve actually been word of mouth for, 10 years. Really? I’ve been using the technology on wind. For over 20, since I think 2003 was my first set of towers in the Mojave desert

Allen Hall: But that’s that’s an amazing piece to this I think your story Is that you’ve done your homework and you’ve been in industry a long time you understand The physics i’ll call it associated with wind turbines motors generators that electrical machines that then You can then used to happen 40, 50 years ago, when I was a kid that those people were around all the time.

You could walk into a motor or a winding shop and people knew how these things worked and we’ve lost some of that. So you’re the part of that architecture of your, that kind of carryover into, hey we already know this stuff. Now we just need to apply some common sense to it and use it to our advantage, which is what you’ve done.

Howard Penrose: Yeah and we continue to do it. People go why aren’t you worrying about how many you sell? It’s I have no overheads. I don’t have a hundred people that I have to pay. I just, there’s only a handful of us. And with all the systems we have in the field what we do is we work ourselves out of work by building all the rules into the software.

We know that intrusive maintenance introduces faults. So everything we do, we try to do as non intrusively as possible.

Allen Hall: This is why you’re on the podcast, because I want to make sure that the select portion of the world that doesn’t know you exist then finds you. Because it’s a quick diagnostic tool, and that’s, and that was the input I got from the O& M people.

People operation maintenance people is that it’s a huge help. It’s such a simple device. They plug in you get the data it analyzes it doesn’t take a lot of Hand holding there Usually as soon as the data pops up it tells you exactly what it sees Right and you always have Howard to call if you get confused, but basically that thing tells you what’s wrong Quickly, and then you can go debug your turbine, or at least have a health status on your turbine, a real health status on your turbine without a lot of work.

That’s genius.

Howard Penrose: It reduces the wear and tear on the technician, right? They’re not climbing to to do other things. One of my good friends now from, the engineer from from H& N, Hank he got up and he explained how boroscope testing for the detection of the wiring issue is only about 50 to 60 percent accurate because you’re looking to see if something’s broken, like the insulation is broken, plus you can’t see the tabs and everything else.

We’re seeing partial fractures long before that occurs. And like I said, Up to 12 to 14 months out. So I’ll usually give it an A through F. Nobody gets an A, but a B through F I’m a horrible professor, but no, no waiting. Those grades. No, B just means continue monitoring. I don’t want people to not check because we have seen like Brazil they’re now just so you’re aware of the wiring issue and everything else.

We were the ones who discovered that was, along with Shermco and H& N, it was a joint project that it was actually fatigue, it’s not a problem with the design of the wiring. It has to do with a a subsynchronous resonance that exists on the grid. So the windings are constantly moving. They’re constantly flexing ring.

Shermco had taken sections of a ring and had a metallurgist look at it. And we could see all of the fatigue points.

Allen Hall: People don’t think of electric machines having fatigue, right? They just think them as just a bunch of coppers spinning around.

Howard Penrose: Everybody since the dawn of time thought that all of these mechanical issues were strictly mechanical.

And we’re finding that there’s electrical reasons for a lot of the mechanical conditions and there’s possible solutions to them. In fact, some of those solutions have already been worked on. But not for this reason.

Allen Hall: And that’s what I think that’s the point, right? Is that we’re in some measure, we have old technology, proven technology, but we’re changing it drastically in the way that we feed it.

Howard Penrose: From both directions, it’s not just the power generation, but we spend a lot of time on in the industrial side is what the heck they’re putting back in the system and utilities, we’ll go in, we’ll see these horrible harmonic conditions in power. ground and neutral. And we’re trying to correct it and the utilities are all going we don’t care about that.

It means nothing. We don’t bill on that. No joke. It’s wait a minute, this is actually consuming a ton of energy. Plus it’s really dumping a lot of garbage back into the system that works its way all the way back because While the transformers and certain filters take some of it out, I can go onto the bulk grid and see some of those oscillations.

Allen Hall: And that’s if you’re a wind turbine operator and you’re living with these conditions, you wouldn’t, your first thought is there’s something wrong with the OEM equipment that I purchased. I need to go debug this thing. But the mere fact that it’s connected to the grid may be driving the problem on the turbine.

And we don’t think about it that way. We think about turbine out, not grid in.

Howard Penrose: Yeah. And then a combination of, Some of the sites will do VAR correction or voltage correction and they’ll be correcting for their site next door. You know what I mean? So one site won’t be doing it, the other site will depending on the controls.

And you find that one side or the other has a higher rate of failure of all their components because of the oscillation that occurs as a direct result.

Allen Hall: Create a tank circuit. Yeah. But those, again this is, as we were talking about earlier the number of electrical engineers on staff at some of these operators is like a 1%, maybe?

2 percent of the staff? 2 percent if you’re lucky. Which there are electrical machines. That’s what they do. We need to have, we need to be a little bit I don’t want to say smarter about it, but we have tools. And this is where Empath come in and where you come in and MotorDoc comes in, you have the tools.

They’re here.

Howard Penrose: And what’s really funny about it is it’s mechanical types like vibration analysts and mechanical engineers that understand the signature they’re looking at. But they hear electrical signature analysis and all of a sudden everybody’s afraid. Or they go, oh no, that’s an electrical issue, that’s for the electricians.

No, actually, the technology was originally developed to look for bearing and gear issues in motor operated valves in the nuclear power industry. It was never meant to look at rotors. It was never meant to look at all this other stuff. It was just incidental that it did it. And, um, it’s, what’s, it’s, what’s fascinating about, the technology and its application.

Allen Hall: It’s wonderful. It’s wonderful. And for those who haven’t seen the system, how do they get onto your website? How do they find you?

Howard Penrose: They can, they can go straight. The easiest way to go is motordoc. com motordoc.com and then they can go to EmpathCMS which i have some videos of wind turbine stuff or MotorDoc ai where i have a little you know podcast of maybe 50 people if i’m lucky where i talk about a lot of this and show how it works and so on so i’m trying to get the information out i published a book on it Practical Electrical and Current Signature Analysis of Electric Machinery and Systems, which includes a chapter on wind turbines.

Allen Hall: I really appreciate you being on this podcast. I like talking to electrical people that are knowledgeable and have had experience in industry for a long time because you’re such a huge resource to everybody and we need to be using you more than we probably are. But, and it’s good to get the word out, right?

Because there’s some parts of the world and some parts of America that may not have heard of you. So let’s get the word out. Hey, go check out Motordoc and get ahold of Howard because he’s a resource. Howard, thank you so much for being on the podcast.

Howard Penrose: Absolutely. Thank you.

https://weatherguardwind.com/empathcms-fast-fault-detection-wind-turbines/

Renewable Energy

BladeBUG Tackles Serial Blade Defects with Robotics

Weather Guard Lightning Tech

BladeBUG Tackles Serial Blade Defects with Robotics

Chris Cieslak, CEO of BladeBug, joins the show to discuss how their walking robot is making ultrasonic blade inspections faster and more accessible. They cover new horizontal scanning capabilities for lay down yards, blade root inspections for bushing defects, and plans to expand into North America in 2026.

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

Welcome to Uptime Spotlight, shining Light on Wind. Energy’s brightest innovators. This is the Progress Powering Tomorrow.

Allen Hall: Chris, welcome back to the show.

Chris Cieslak: It’s great to be back. Thank you very much for having me on again.

Allen Hall: It’s great to see you in person, and a lot has been happening at Blade Bugs since the last time I saw Blade Bug in person. Yeah, the robot. It looks a lot different and it has really new capabilities.

Chris Cieslak: So we’ve continued to develop our ultrasonic, non-destructive testing capabilities of the blade bug robot.

Um, but what we’ve now added to its capabilities is to do horizontal blade scans as well. So we’re able to do blades that are in lay down yards or blades that have come down for inspections as well as up tower. So we can do up tower, down tower inspections. We’re trying to capture. I guess the opportunity to inspect blades after transportation when they get delivered to site, to look [00:01:00] for any transport damage or anything that might have been missed in the factory inspections.

And then we can do subsequent installation inspections as well to make sure there’s no mishandling damage on those blades. So yeah, we’ve been just refining what we can do with the NDT side of things and improving its capabilities

Joel Saxum: was that need driven from like market response and people say, Hey, we need, we need.

We like the blade blood product. We like what you’re doing, but we need it here. Or do you guys just say like, Hey, this is the next, this is the next thing we can do. Why not?

Chris Cieslak: It was very much market response. We had a lot of inquiries this year from, um, OEMs, blade manufacturers across the board with issues within their blades that need to be inspected on the ground, up the tap, any which way they can.

There there was no, um, rhyme or reason, which was better, but the fact that he wanted to improve the ability of it horizontally has led the. Sort of modifications that you’ve seen and now we’re doing like down tower, right? Blade scans. Yeah. A really fast breed. So

Joel Saxum: I think the, the important thing there is too is that because of the way the robot is built [00:02:00] now, when you see NDT in a factory, it’s this robot rolls along this perfectly flat concrete floor and it does this and it does that.

But the way the robot is built, if a blade is sitting in a chair trailing edge up, or if it’s flap wise, any which way the robot can adapt to, right? And the idea is. We, we looked at it today and kind of the new cage and the new things you have around it with all the different encoders and for the heads and everything is you can collect data however is needed.

If it’s rasterized, if there’s a vector, if there’s a line, if we go down a bond line, if we need to scan a two foot wide path down the middle of the top of the spa cap, we can do all those different things and all kinds of orientations. That’s a fantastic capability.

Chris Cieslak: Yeah, absolutely. And it, that’s again for the market needs.

So we are able to scan maybe a meter wide in one sort of cord wise. Pass of that probe whilst walking in the span-wise direction. So we’re able to do that raster scan at various spacing. So if you’ve got a defect that you wanna find that maximum 20 mil, we’ll just have a 20 mil step [00:03:00] size between each scan.

If you’ve got a bigger tolerance, we can have 50 mil, a hundred mil it, it’s so tuneable and it removes any of the variability that you get from a human to human operator doing that scanning. And this is all about. Repeatable, consistent high quality data that you can then use to make real informed decisions about the state of those blades and act upon it.

So this is not about, um, an alternative to humans. It’s just a better, it’s just an evolution of how humans do it. We can just do it really quick and it’s probably, we, we say it’s like six times faster than a human, but actually we’re 10 times faster. We don’t need to do any of the mapping out of the blade, but it’s all encoded all that data.

We know where the robot is as we walk. That’s all captured. And then you end up with really. Consistent data. It doesn’t matter who’s operating a robot, the robot will have those settings preset and you just walk down the blade, get that data, and then our subject matter experts, they’re offline, you know, they are in their offices, warm, cozy offices, reviewing data from multiple sources of robots.

And it’s about, you know, improving that [00:04:00] efficiency of getting that report out to the customer and letting ’em know what’s wrong with their blades, actually,

Allen Hall: because that’s always been the drawback of, with NDT. Is that I think the engineers have always wanted to go do it. There’s been crush core transportation damage, which is sometimes hard to see.

You can maybe see a little bit of a wobble on the blade service, but you’re not sure what’s underneath. Bond line’s always an issue for engineering, but the cost to take a person, fly them out to look at a spot on a blade is really expensive, especially someone who is qualified. Yeah, so the, the difference now with play bug is you can have the technology to do the scan.

Much faster and do a lot of blades, which is what the de market demand is right now to do a lot of blades simultaneously and get the same level of data by the review, by the same expert just sitting somewhere else.

Chris Cieslak: Absolutely.

Joel Saxum: I think that the quality of data is a, it’s something to touch on here because when you send someone out to the field, it’s like if, if, if I go, if I go to the wall here and you go to the wall here and we both take a paintbrush, we paint a little bit [00:05:00] different, you’re probably gonna be better.

You’re gonna be able to reach higher spots than I can.

Allen Hall: This is true.

Joel Saxum: That’s true. It’s the same thing with like an NDT process. Now you’re taking the variability of the technician out of it as well. So the data quality collection at the source, that’s what played bug ducts.

Allen Hall: Yeah,

Joel Saxum: that’s the robotic processes.

That is making sure that if I scan this, whatever it may be, LM 48.7 and I do another one and another one and another one, I’m gonna get a consistent set of quality data and then it’s goes to analysis. We can make real decisions off.

Allen Hall: Well, I, I think in today’s world now, especially with transportation damage and warranties, that they’re trying to pick up a lot of things at two years in that they could have picked up free installation.

Yeah. Or lifting of the blades. That world is changing very rapidly. I think a lot of operators are getting smarter about this, but they haven’t thought about where do we go find the tool.

Speaker: Yeah.

Allen Hall: And, and I know Joel knows that, Hey, it, it’s Chris at Blade Bug. You need to call him and get to the technology.

But I think for a lot of [00:06:00] operators around the world, they haven’t thought about the cost They’re paying the warranty costs, they’re paying the insurance costs they’re paying because they don’t have the set of data. And it’s not tremendously expensive to go do. But now the capability is here. What is the market saying?

Is it, is it coming back to you now and saying, okay, let’s go. We gotta, we gotta mobilize. We need 10 of these blade bugs out here to go, go take a scan. Where, where, where are we at today?

Chris Cieslak: We’ve hads. Validation this year that this is needed. And it’s a case of we just need to be around for when they come back round for that because the, the issues that we’re looking for, you know, it solves the problem of these new big 80 a hundred meter plus blades that have issues, which shouldn’t.

Frankly exist like process manufacturer issues, but they are there. They need to be investigated. If you’re an asset only, you wanna know that. Do I have a blade that’s likely to fail compared to one which is, which is okay? And sort of focus on that and not essentially remove any uncertainty or worry that you have about your assets.

’cause you can see other [00:07:00] turbine blades falling. Um, so we are trying to solve that problem. But at the same time, end of warranty claims, if you’re gonna be taken over these blades and doing the maintenance yourself, you wanna know that what you are being given. It hasn’t gotten any nasties lurking inside that’s gonna bite you.

Joel Saxum: Yeah.

Chris Cieslak: Very expensively in a few years down the line. And so you wanna be able to, you know, tick a box, go, actually these are fine. Well actually these are problems. I, you need to give me some money so I can perform remedial work on these blades. And then you end of life, you know, how hard have they lived?

Can you do an assessment to go, actually you can sweat these assets for longer. So we, we kind of see ourselves being, you know, useful right now for the new blades, but actually throughout the value chain of a life of a blade. People need to start seeing that NDT ultrasonic being one of them. We are working on other forms of NDT as well, but there are ways of using it to just really remove a lot of uncertainty and potential risk for that.

You’re gonna end up paying through the, you know, through the, the roof wall because you’ve underestimated something or you’ve missed something, which you could have captured with a, with a quick inspection.

Joel Saxum: To [00:08:00] me, NDT has been floating around there, but it just hasn’t been as accessible or easy. The knowledge hasn’t been there about it, but the what it can do for an operator.

In de-risking their fleet is amazing. They just need to understand it and know it. But you guys with the robotic technology to me, are bringing NDT to the masses

Chris Cieslak: Yeah.

Joel Saxum: In a way that hasn’t been able to be done, done before

Chris Cieslak: that. And that that’s, we, we are trying to really just be able to roll it out at a way that you’re not limited to those limited experts in the composite NDT world.

So we wanna work with them, with the C-N-C-C-I-C NDTs of this world because they are the expertise in composite. So being able to interpret those, those scams. Is not a quick thing to become proficient at. So we are like, okay, let’s work with these people, but let’s give them the best quality data, consistent data that we possibly can and let’s remove those barriers of those limited people so we can roll it out to the masses.

Yeah, and we are that sort of next level of information where it isn’t just seen as like a nice to have, it’s like an essential to have, but just how [00:09:00] we see it now. It’s not NDT is no longer like, it’s the last thing that we would look at. It should be just part of the drones. It should inspection, be part of the internal crawlers regimes.

Yeah, it’s just part of it. ’cause there isn’t one type of inspection that ticks all the boxes. There isn’t silver bullet of NDT. And so it’s just making sure that you use the right system for the right inspection type. And so it’s complementary to drones, it’s complimentary to the internal drones, uh, crawlers.

It’s just the next level to give you certainty. Remove any, you know, if you see something indicated on a a on a photograph. That doesn’t tell you the true picture of what’s going on with the structure. So this is really about, okay, I’ve got an indication of something there. Let’s find out what that really is.

And then with that information you can go, right, I know a repair schedule is gonna take this long. The downtime of that turbine’s gonna be this long and you can plan it in. ’cause everyone’s already got limited budgets, which I think why NDT hasn’t taken off as it should have done because nobody’s got money for more inspections.

Right. Even though there is a money saving to be had long term, everyone is fighting [00:10:00] fires and you know, they’ve really got a limited inspection budget. Drone prices or drone inspections have come down. It’s sort, sort of rise to the bottom. But with that next value add to really add certainty to what you’re trying to inspect without, you know, you go to do a day repair and it ends up being three months or something like, well

Allen Hall: that’s the lightning,

Joel Saxum: right?

Allen Hall: Yeah. Lightning is the, the one case where every time you start to scarf. The exterior of the blade, you’re not sure how deep that’s going and how expensive it is. Yeah, and it always amazes me when we talk to a customer and they’re started like, well, you know, it’s gonna be a foot wide scarf, and now we’re into 10 meters and now we’re on the inside.

Yeah. And the outside. Why did you not do an NDT? It seems like money well spent Yeah. To do, especially if you have a, a quantity of them. And I think the quantity is a key now because in the US there’s 75,000 turbines worldwide, several hundred thousand turbines. The number of turbines is there. The number of problems is there.

It makes more financial sense today than ever because drone [00:11:00]information has come down on cost. And the internal rovers though expensive has also come down on cost. NDT has also come down where it’s now available to the masses. Yeah. But it has been such a mental barrier. That barrier has to go away. If we’re going going to keep blades in operation for 25, 30 years, I

Joel Saxum: mean, we’re seeing no

Allen Hall: way you can do it

Joel Saxum: otherwise.

We’re seeing serial defects. But the only way that you can inspect and or control them is with NDT now.

Allen Hall: Sure.

Joel Saxum: And if we would’ve been on this years ago, we wouldn’t have so many, what is our term? Blade liberations liberating

Chris Cieslak: blades.

Joel Saxum: Right, right.

Allen Hall: What about blade route? Can the robot get around the blade route and see for the bushings and the insert issues?

Chris Cieslak: Yeah, so the robot can, we can walk circumferentially around that blade route and we can look for issues which are affecting thousands of blades. Especially in North America. Yeah.

Allen Hall: Oh yeah.

Chris Cieslak: So that is an area that is. You know, we are lucky that we’ve got, um, a warehouse full of blade samples or route down to tip, and we were able to sort of calibrate, verify, prove everything in our facility to [00:12:00] then take out to the field because that is just, you know, NDT of bushings is great, whether it’s ultrasonic or whether we’re using like CMS, uh, type systems as well.

But we can really just say, okay, this is the area where the problem is. This needs to be resolved. And then, you know, we go to some of the companies that can resolve those issues with it. And this is really about played by being part of a group of technologies working together to give overall solutions

Allen Hall: because the robot’s not that big.

It could be taken up tower relatively easily, put on the root of the blade, told to walk around it. You gotta scan now, you know. It’s a lot easier than trying to put a technician on ropes out there for sure.

Chris Cieslak: Yeah.

Allen Hall: And the speed up it.

Joel Saxum: So let’s talk about execution then for a second. When that goes to the field from you, someone says, Chris needs some help, what does it look like?

How does it work?

Chris Cieslak: Once we get a call out, um, we’ll do a site assessment. We’ve got all our rams, everything in place. You know, we’ve been on turbines. We know the process of getting out there. We’re all GWO qualified and go to site and do their work. Um, for us, we can [00:13:00] turn up on site, unload the van, the robot is on a blade in less than an hour.

Ready to inspect? Yep. Typically half an hour. You know, if we’ve been on that same turbine a number of times, it’s somewhere just like clockwork. You know, muscle memory comes in, you’ve got all those processes down, um, and then it’s just scanning. Our robot operator just presses a button and we just watch it perform scans.

And as I said, you know, we are not necessarily the NDT experts. We obviously are very mindful of NDT and know what scans look like. But if there’s any issues, we have a styling, we dial in remote to our supplement expert, they can actually remotely take control, change the settings, parameters.

Allen Hall: Wow.

Chris Cieslak: And so they’re virtually present and that’s one of the beauties, you know, you don’t need to have people on site.

You can have our general, um, robot techs to do the work, but you still have that comfort of knowing that the data is being overlooked if need be by those experts.

Joel Saxum: The next level, um, commercial evolution would be being able to lease the kit to someone and or have ISPs do it for [00:14:00] you guys kinda globally, or what is the thought

Chris Cieslak: there?

Absolutely. So. Yeah, so we to, to really roll this out, we just wanna have people operate in the robots as if it’s like a drone. So drone inspection companies are a classic company that we see perfectly aligned with. You’ve got the sky specs of this world, you know, you’ve got drone operator, they do a scan, they can find something, put the robot up there and get that next level of information always straight away and feed that into their systems to give that insight into that customer.

Um, you know, be it an OEM who’s got a small service team, they can all be trained up. You’ve got general turbine technicians. They’ve all got G We working at height. That’s all you need to operate the bay by road, but you don’t need to have the RAA level qualified people, which are in short supply anyway.

Let them do the jobs that we are not gonna solve. They can do the big repairs we are taking away, you know, another problem for them, but giving them insights that make their job easier and more successful by removing any of those surprises when they’re gonna do that work.

Allen Hall: So what’s the plans for 2026 then?

Chris Cieslak: 2026 for us is to pick up where 2025 should have ended. [00:15:00] So we were, we were meant to be in the States. Yeah. On some projects that got postponed until 26. So it’s really, for us North America is, um, what we’re really, as you said, there’s seven, 5,000 turbines there, but there’s also a lot of, um, turbines with known issues that we can help determine which blades are affected.

And that involves blades on the ground, that involves blades, uh, that are flying. So. For us, we wanna get out to the states as soon as possible, so we’re working with some of the OEMs and, and essentially some of the asset owners.

Allen Hall: Chris, it’s so great to meet you in person and talk about the latest that’s happening.

Thank you. With Blade Bug, if people need to get ahold of you or Blade Bug, how do they do that?

Chris Cieslak: I, I would say LinkedIn is probably the best place to find myself and also Blade Bug and contact us, um, through that.

Allen Hall: Alright, great. Thanks Chris for joining us and we will see you at the next. So hopefully in America, come to America sometime.

We’d love to see you there.

Chris Cieslak: Thank you very [00:16:00] much.

Renewable Energy

Understanding the U.S. Constitution

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Hillsdale College is a rightwing Christian extremist organization that ostensibly honors the United States Constitution.

Here’s their quiz, which should be called the “Constitutional Trivia Quiz.”, whose purpose is obviously to convince Americans of their ignorance.

When I teach, I’m going for understanding of the topic, not the memorization of useless information.

Renewable Energy

Bravery Meets Tragedy: An Unending Story

Here’s a story:

Here’s a story:

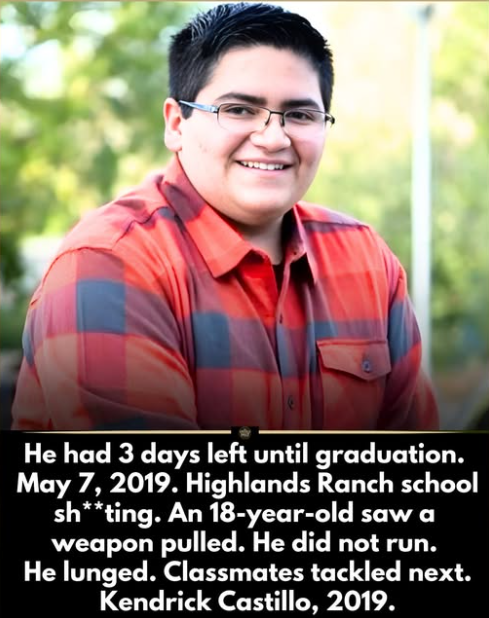

He had 3 days left until graduation.

Kendrick Castillo was 18. A robotics student. College bound. Accepted into an engineering program. The final week of school felt like countdown, not crisis.

Then a weapon appeared inside a classroom.

Students froze.

Kendrick did not.

Witnesses say he moved instantly. He lunged toward the attacker. No hesitation. No calculation.

Two other students followed his lead.

Gunfire erupted.

Kendrick was fatally sh*t.

But his movement changed the room.

Classmates were able to tackle and restrain the attacker until authorities arrived. Investigators later stated that the confrontation disrupted the attack and likely prevented additional casualties.

In seconds, an 18-year-old made a decision most adults pray they never face.

Afterward, the silence was heavier than the noise.

At graduation, his name was called.

His diploma was awarded posthumously. The arena stood in collective applause. An empty seat. A cap and gown without the student inside it.

His robotics teammates remembered him as curious. Competitive. Kind. Someone who solved problems instead of avoiding them.

He had planned to build machines.

Instead, he built a moment.

A moment that classmates say gave them time.

Time to escape.

Two points:

If you can read this without tears welling up in your eyes, you’re a far more stoic person than I.

Since Big Money has made it impossible for the United States to implement the same common-sense gun laws that exist in the rest of the planet, this story will reduplicate itself into perpetuity.

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits