Oil and gas pipelines are everywhere and nowhere. They hide in plain sight, buried and marked above ground only by a mown right-of-way and the periodic yellow post or mile marker. Because they are not highly visible like transmission lines or power plants, they typically aren’t given much thought — unless a pipeline easement touches your own property.

Pipeline accidents — leaks, spills, and explosions — hold attention for a few news cycles and then fade away. The claims by pipeline operators are usually along the lines of “this was a rare event, and we have safeguards to keep it from happening again.” But according to a FracTracker analysis of oil and gas pipeline incidents reported between 2010 and 2023, a fire erupts every 4.2 days, an explosion occurs every 12.2 days, a person is killed in one of these incidents every 29 days, and an injury is reported every 6.5 days. During this time period, there were 2,955 incidents reported just along methane gas gathering, transmission, and distribution lines, resulting in 149 fatalities and 697 injuries.

So, these events truly are not so rare after all. Yet, we continue to add more and more miles of dangerous new pipelines every year.

SACE’s new paper: “A Pipeline of Problems”

Below is an overview of a few of the new and proposed pipeline projects in North Carolina, Tennessee, and South Carolina. SACE’s new paper “A Pipeline of Problems” goes deeper into the topics of pipeline risk classifications, proximity to homes and daycares, pipeline construction failures, pipeline exposure above ground, geologic risk such as earthquakes and landslides, and the impact climate change is having on East Coast rain events and pipeline safety. All of these issues lead us to the question: Why are we still building pipelines?

A Sampling of New Pipeline Projects in the Southeast

First, let’s inventory some of the recent fossil gas pipeline projects impacting the Carolinas and Tennessee and fueling Southeastern utilities’ planned gas plant buildout. The biggest that has been completed to date is the Mountain Valley Pipeline (MVP), which stops just shy of North Carolina. This brand new 42-inch pipeline is 303 miles and traverses very steep, mountainous terrain (including the Appalachian Trail), transporting fracked Marcellus and Utica shale gas via West Virginia and Virginia to the massive Williams Transcontinental pipeline (Transco).

Source: EIA maps

Transco dates back to 1949 and consists of three to four pipelines stretching from the Gulf of Mexico up the East Coast. Traditionally, this pipeline ran south to north, but it now has increasing bi-directional capability in order to deliver Marcellus and Utica shale gas to the south. The MVP entered service on June 14, 2024, 10 years after first filing initial plans at the Federal Energy and Regulatory Commission (FERC). MVP is a “greenfield” pipeline, meaning that it traverses land that previously did not have existing pipeline infrastructure.

MVP Southgate

In North Carolina, the MVP has announced plans to build an additional 31 miles of 30-inch pipeline, called MVP Southgate, starting from the MVP mainline end at Transco in Pittsylvania County, Virginia, and proceeding into Rockingham County, North Carolina (see map below). This proposed pipeline has been publicly planned since 2019, but MVP announced a scope change and has been granted an extension by FERC to begin service by June 18, 2026, though new route details were only filed on February 3, 2025.

Enbridge T15 Reliability Project

Another North Carolina pipeline project is the Enbridge T15 Reliability Project. This 45-mile project would parallel the existing 63-year-old Enbridge T15 pipeline (which starts at the Transco pipeline in Rockingham County and proceeds into Person County) to the proposed new Duke Energy Progress 2,720 MW fossil gas plant in Person County.

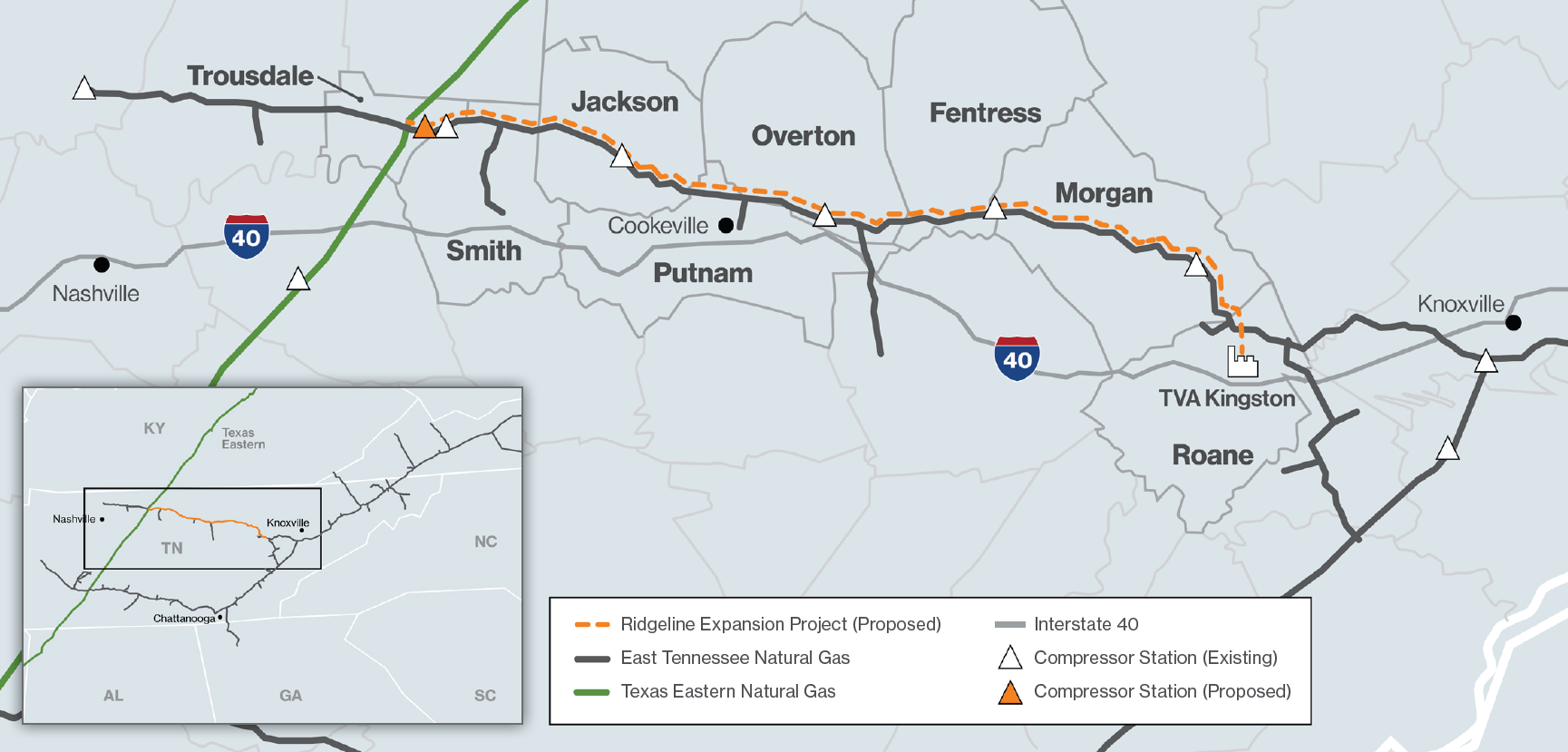

Cumberland Pipeline and Ridgeline Expansion Pipeline

In Tennessee, there are currently three proposed pipelines in the works to fuel new TVA gas plants: 1) the EQT Cumberland Pipeline (first map below) will be 32 miles of greenfield pipeline construction, 2) the ETNG Ridgeline Expansion (second map below) will be 122 miles of new pipeline that will parallel the existing Line 3100 that was built in 1949 and is currently owned by Enbridge/ETNG, and 3) a Kinder Morgan pipeline that is still in early planning stages that would supply TVA’s proposed Cheatham gas plant.

Cumberland Pipeline. Map Source: https://www.kindermorgan.com/Operations/Projects/cumberland-project

Ridgeline Expansion Project. Map source: https://www.enbridge.com/projects-and-infrastructure/projects/ridgeline-expansion-project/project-map

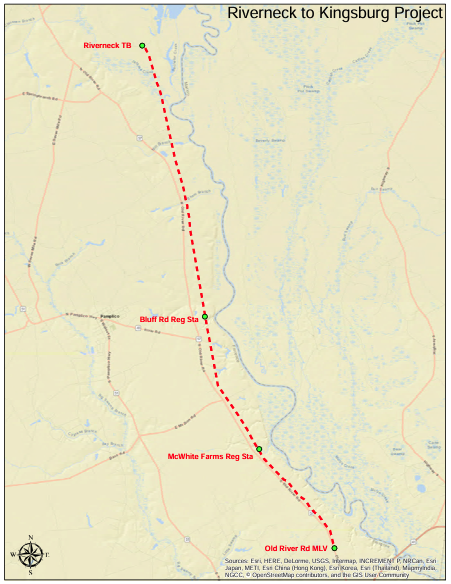

Dominion Riverneck to Kingsburg

In South Carolina, Dominion is proposing a 15-mile pipeline, Riverneck to Kingsburg, paralleling part of the existing gas network called Carolina Gas Transmission (owned by Berkshire Hathaway) along the Pee Dee River. In addition, Dominion and Santee Cooper are discussing the need for a new greenfield pipeline branching off of the Kinder Morgan/SONAT gas system in Georgia to serve a proposed gas plant at Canadys in the Lowcountry.

Transco Southeast Supply Enhancement Project

Transco itself has a major expansion project called the Southeast Supply Enhancement Project in the works that would add 50 miles of new pipeline segments in Virginia and North Carolina, as well as compressor station upgrades in Virginia, North Carolina, South Carolina, Georgia, and Alabama, to push more gas through that system. This increased capacity (1.6 million dekatherms per day) will enable additional projects, such as the T15, to serve the proposed utility gas plant build-out in North Carolina, South Carolina, and Georgia.

Kinder Morgan, which owns a large gas pipeline network called SONAT that services Georgia and South Carolina, has announced a similar 1.3-million dekatherms per day expansion project called the Kinder Morgan South System Expansion 4.

In short, the proposed Southeast utility gas plant buildout is causing a frenzy of pipeline projects. This necessitates examining safety issues framed within our particular Southeastern proposed pipeline projects. There are terrific resources available nationally, such as those maintained by the Pipeline Safety Trust, but we look particularly at Southeastern issues and examples, such as landslide risks made real by Hurricane Helene.

Read our white paper, “A Pipeline of Problems,” to learn more about the risks pipelines pose for our Southeastern communities and families.

The post A Pipeline of Problems appeared first on SACE | Southern Alliance for Clean Energy.

Renewable Energy

Raw Stupidity: Yet One More Reason that Trump Must Go

From the Huffington Post:

From the Huffington Post:

A senior FBI officer struggled to answer basic questions about antifa, despite characterizing the organization as “the most immediate violent threat” the US faces.

At a House Committee on Homeland Security hearing on Thursday, Michael Glasheen, operations director of the national security branch of the FBI, said he agreed with President Donald Trump that antifa is one of the greatest national security threats to the country.

The answer, of course, is that “Antifa” is a concept, not an organization. It refers to anyone who is against fascism. It has no headquarters, no leaders, and no members.

Now, it is true that people with these views can be violent. When my father led a crew of his fellow anti-fascists, flying a B-17 bomber in World War 2, they completed 29 successful missions, destroying Nazi oil refineries. Were Nazi soldiers killed in the process? I never asked him that, and he probably didn’t know, as they were flying at 29,000 feet, but it seems extremely unlikely that no one died.

In peacetime, we antifa people are non-violent. We may be marching for BLM, or encouraging the use of science in policymaking, or expressing our view that the United States should not have a king.

The FBI must understand this; they must be saying this purely to placate Trump. No one can be that stupid.

Renewable Energy

Hydrokinetics Gone Awry

When I came across the meme at left, I was instantly reminded of a guy who called me from Baltimore, MD about 15 years ago, anxious for me to hunt up investors in an invention he had created. I was having a hard time understanding the concept he was describing, and so he told me, “Think of it as a river in a box.”

When I came across the meme at left, I was instantly reminded of a guy who called me from Baltimore, MD about 15 years ago, anxious for me to hunt up investors in an invention he had created. I was having a hard time understanding the concept he was describing, and so he told me, “Think of it as a river in a box.”

“Ah! Now I get it. You have a box full of standing water. You add energy to it to get it moving, and then our extract energy from the moving water. And you think that you can extract more energy than you put into it.”

“Yes!” he said excitedly.

I calmly told him that this violates the laws of physics, specifically the first and second laws of thermodynamics, but he wasn’t “having it.” I wished him a pleasant good night and asked him to let me know when he had built a working prototype.

I’m still hoping to hear from him again.

Renewable Energy

Benefits of Solar Power Solution in Manufacturing Facilities

-

Climate Change4 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases4 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits

-

Climate Change2 years ago

Why airlines are perfect targets for anti-greenwashing legal action