Last Updated on October 15, 2025

Did you know the average newborn goes through 10-12 diapers per day? That’s a lot of waste – and a lot of time spent in diapers.

Most babies have more sensitive skin than adults, as their skin hasn’t fully developed yet. The protective hydrolipidic film is still very thin, which makes infant skin more vulnerable to harsh external factors.

Some of the links in this post are affiliate links; for more information please see my disclosure policy.

Those external factors include diapers. Babies spend a lot of time getting in (and out) of them. So it’s important to choose non toxic diapers that are gentle on both skin and planet. Here are the best non toxic diapers on the market.

which diapers are the least toxic?

The diapers that are least toxic include ones made from plant-based or cotton materials. Look for brands that omit harsh chemicals like chlorine, phthalates, and PFAs.

Many diaper components are made up of plastic, which is hard to avoid in the name of efficiency.

That being said, it’s best to choose diapers from brands that minimize the amount of plastic in their products. Plastic materials can emit VOCs known to harm health.

Here are some general guidelines to adhere to when choosing diapers:

- Choose diapers that disclose the ingredients (some don’t!). Avoid anything with fragrance, lotion, or other skin-conditioning adhesives.

- Look for brands that minimize the amount of plastic in their products.

- Consider cloth diapers, ideally made from organic cotton.

- Opt for brands that use unbleached pulp or pulp bleached without chlorine

- Try to choose plain, undyed diapers with minimal designs (dyes can be contaminated with toxic heavy metals).

- Check for certifications like Forest Stewardship Council or EWG certified.

is Huggies or Pampers less toxic?

In terms of being less toxic, Huggies has stated all of their diapers are free of fragrances, phthalates, parabens, and elemental chlorine. They’ve also partnered with Terracycle to offer plastic film recycling options.

Pampers diapers are made without parabens, natural rubber latex and elemental chlorine. But only their Pure diapers are made without fragrance (and many mothers online have complained of Pampers’ strong scent).

However, Pampers’ factories are zero manufacturing waste to landfill and they use FSC certified wood pulp.

Both brands list their ingredients on their websites, so definitely read them for yourself before making a purchase. Just be mindful both brands also use colorants and printing inks to make designs and/or color change technology.

which diaper brands are safe for babies?

The diaper brands safe for babies are listed below. There’s a mix of disposable and cloth diapers, so there’s something for everyone.

However, be mindful that every baby is different and what works for one, doesn’t always work for another. For example, certain brands may fit your baby like a glove, whereas others may be too big: It’s all about experimenting and finding what works for your baby.

You can use this list as a starting point to help you choose a better, safer choice for your child. None of the brands listed here use fragrance, parabens, or other harsh chemicals.

I’ve gone ahead and highlighted some of my favorite features of each brand, but it isn’t an exhaustive list. Be sure to check out their websites for more information.

Also, if you cloth diaper, don’t forget to consider eco-friendly baby detergent brands because you’ll be doing a bit more laundry!

1. healthy baby

- Offers disposable and cloth diapering options

- Six sizes, not including newborn (N or N/1)

- Plant-based materials including organic cotton + FSC certified pulp

- 12 hour leak protection

- No chemical wetness indicator

- EWG certified

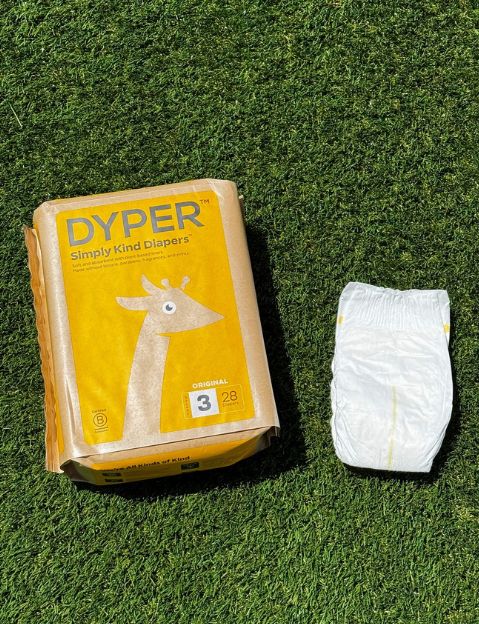

2. dyper

- Disposable diapers

- Six sizes, not including newborn (NB)

- Plant-based materials, including FSC-certified pulp

- 12-hour leak protection

- No inks, prints or dyes

- Offers REDYPER service to compost diapers through weekly pickup

3. coterie

- Disposable diapers

- Seven sizes, not including newborn (N or N+1)

- 25% plant-based, made with wood pulp from sustainably manages forests

- 12-hour leak protection

- Wetness indicator

- Cruelty-free

- OEKO-TEX STANDARD 100 Certified

4. esembly baby

- Cloth diapers

- Two sizes, based on pounds

- Made of organic cotton + upcycled TPU

- Recommended to change an awake baby every 2-3 hours

- Wet bags sold separately to hold dirty diapers while out

- Pre-loved options to buy and sell available

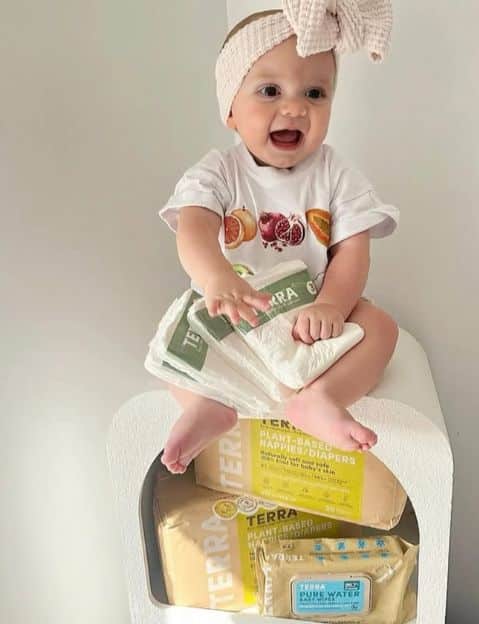

5. terra

- Disposable diapers

- Six sizes

- 85% plant-based, including FSC-certified pulp

- 12-hour leak-proof protection

- Plant-based wetness indicator

- Ink on product + packaging is food grade

- Packaging is made from recyclable kraft paper + rice

6. freestyle

- Disposable diapers

- Six sizes

- 7-layer protection for 14x better absorption

- Delivered in 1 month long supplies

- FSC certified pulp

- EWG verified

Which of these sustainable diaper options would you choose? Let me know in the comments!

The post 6 Best Non Toxic Diapers For Babies appeared first on Going Zero Waste.

Green Living

Classic Sustainability In Your Ear: The Ocean River Institute’s Natural Lawn Challenge for Climate Action

Turn back the clock with this classic interview that will get you ready for Spring yard care planning. A lawn may be beautiful but it can take a heavy toll on the environment, accounting for between 30% and 60% of residential water use in the United States. Rob Moir, Ph.D., is president and executive director of the Ocean River Institute in Cambridge, Massachusetts. ORI works with residential lawn owners to heal damaged ecosystems by restoring coastal areas to lessen the destructive impacts of climate change. The benefits of a natural lawn reach far beyond reduced local water pollution, eliminating chemicals that can contribute to cancers, diabetes, Alzheimer’s disease, and other cellular diseases. Natural lawns are also better for local pollinators and store much more carbon than heavily fertilized lawns. If you considered removing your lawn to play a part in the battle against climate change, this interview may change your mind — a healthy lawn is a powerful carbon sink.

The Ocean River Institute is recruiting Massachusetts communities, town by town, to take a pledge to follow natural lawn practices in the Healthy Soils for Climate Restoration Challenge. You don’t need to live in Massachusetts to participate and learn about the alternatives to the traditional, chemical-intensive lawn practices that use Roundup, a source of glyphosates that kills soil-dwelling fungi and local pollinators, and fast-acting nitrogen fertilizers. You can learn more about the Ocean River Institute at www.oceanriver.org.

Rob has contributed many articles about climate change and the history of environmental change since this interview, including:

- Finding a Northwest Passage to the Sea

- Turning the Tide—How Land and Water Shape Our Climate Future

- Learning from Captain Scoresby’s Ten-gallon Fir-Cask

- Earth Savvy?

- Let the Ground Keep Falling Rainwater

- The Sultans of Swag Versus Looking at Clouds from Both Sides Now

- Subscribe to Sustainability in Your Ear on iTunes and Apple Podcasts.

- Follow Sustainability in Your Ear on Spreaker, iHeartRadio, or YouTube

Editor’s Note: This episode originally aired on May 30, 2022.

The post Classic Sustainability In Your Ear: The Ocean River Institute’s Natural Lawn Challenge for Climate Action appeared first on Earth911.

https://earth911.com/podcast/earth911-podcast-the-ocean-river-institutes-natural-lawn-challenge-for-climate-action/

Green Living

7 Best Sustainable Wedding Dresses for Your Special Day

Choosing your perfect gown can be one of the most exciting decisions for your special day, but for the eco fashionista, it can be a challenge to find a dress that fits your values and style — but these brands have exceptional sustainable wedding dresses you’ll swoon over!

Using earth-minded materials like hemp, cruelty-free peace silk, deadstock recycled fabrics and vintage lace, and producing consciously, either in small batches or handcrafting each individual piece made-to-order, the brands below meet high standards for transparency, ecological sustainability, and fair labor.

[For more sustainable wedding dresses, check out this guide to secondhand wedding dress sites!]

Note that the guide contains affiliate links. As always, we only feature brands that meet strict criteria for sustainability we love, that we think you’ll love too!

1. Christy Dawn

Dreamy dress brand Christy Dawn does not disappoint with their romantic bridal collection! Each piece is more swoon-worthy than the next.

Their three sustainable bridal gowns are made from regenerative silk charmeuse —sourced through BOMBYX, an innovative silk producer using best practices — and colored in a beautiful pearl silk with non-toxic dyes. Each dress is ethically cut and sewn by makers in Los Angeles earning living wages, as with the rest of Christy Dawn’s collections.

The Britta Dress and Fitzgerald Dress are 1920s inspired while the Athena Dress is a more modern (but equally romantic) option. All of these dresses are made-to-order with an estimated timeline of 4 weeks.

Conscious Qualities: Regenerative silk and organic non-toxic dyes, ethically made-to-order in Los Angeles

Price Range: $2,500 – $3,000

Size Range: XS – XL

2. Pure Magnolia

Blending the traditional with the modern, Pure Magnolia designs classic-inspired sustainable wedding dresses with contemporary touches. And each dress is made in their Canadian studio by seamstresses earning fair wages from eco-fabrics, such as organic cotton and hemp silk.

The brand sources recycled fabrics whenever possible as well, and recycles their scrap fabric through FABCYCLE.

Conscious Qualities: Eco-friendly fabrics, locally and fairly made, recycles scrap fabrics

Price Range: $845 – $3,300 CAD

Size Range: 0 – 28

3. Lost in Paris

Lost in Paris crafts each of their creatively designed bohemian-inspired gowns ethically in their Sydney, Australia studio. Unconventional yet undeniably striking, Lost in Paris’ dresses are made from vintage lace and cotton.

Investing in a dress from Lost in Paris is seamless — the brand offers at-home sample try-ons, offers train and sleeve adjustments on several styles, ships their dresses worldwide for free, and even accepts returns. Oh, and, if one of their ready-made sizes doesn’t work for you, you can get a dress designed to your measurements.

Conscious Qualities: Made-to-order model, uses vintage lace, locally made

Price Range: $950 – $3900 AUD

Size Range: XXS – XXL + custom sizing options

For More Slow Fashion Content:

For More Slow Fashion Content:

4. Wear Your Love

Wear Your Love creates feminine, effortless dresses in their Northern California studio that are — in contrast to the majority of wedding dresses on the market — actually comfortable! The brand’s free-spirited designs are made with soft, earth-minded fabrics like organic cotton and each dress is made to order for each bride to their exact measurements.

There are also customizations available for each eco-friendly wedding dress such as train or no train, skirt or sleeve linings, back coverage, skirt style, and more.

Conscious Qualities: Eco-friendly fabrics, made-to-order model, locally and transparently made

Price Range: $680 – $1,700

Size Range: N/A; dresses are made to your measurements

5. Larimeloom

Based in Reggio Emilia, Italy, Larimeloom crafts exceptional custom-made dresses by hand in their atelier. The brand creates comfortable minimalist dresses from durable natural fabrics and colors them with natural or non-toxic dyes.

Larimeloom has also implemented zero waste design techniques, cutting their patterns strategically in order to minimize fabric waste.

Conscious Qualities: Made-to-order model, zero-waste designs, natural fabrics and dyes

Price Range: 650€ – 2,650€

Size Range: XS – XL

6. Sister Organics

Sourcing quality earth-friendly natural fabrics like organic hemp and cotton, Sister Organics creates classic, eco-friendly wedding dresses for UK-based brides.

Each dress is made to order in England, so you can select a pre-defined size, customize the length of a size, or get an entirely different dress made for your measurements.

Conscious Qualities: Eco-friendly fabrics, made-to-order model

Price Range: £125 – £390

Size Range: XXS – XXL + custom sizing

7. Indiebride London

Indiebride’s vintage-inspired sustainable wedding dresses are delicate and romantic yet free-spirited, offering a unique collection for the bride that wants to skip the conventional wedding gown and choose a piece that fits their individual style.

The brand’s conscious wedding dresses are handmade in London using majority natural fibers and can be altered or customized to your specifications.

Conscious Qualities: Made-to-order model, uses many natural fabrics, locally made

Price Range: £1,200 – £1,700

Size Range: 8 – 16 (UK sizes)

More Resources For Your Eco Wedding:

10 Secondhand Wedding Dress Sites for the Eco Bride

7 Ethical Lab-Grown Diamond Engagement and Wedding Rings

17 Brands with Conscious Dresses (great options for bridesmaid dresses in here!)

The post 7 Best Sustainable Wedding Dresses for Your Special Day appeared first on Conscious Life & Style.

Green Living

7 Sustainable Dressers and Armoires to Store it All Away in Style (2026)

Get organized in style with the beautiful sustainable dressers, wardrobes, and armoires from these furniture companies using responsibly-sourced FSC-Certified wood or upcycled wood.

Note that this guide includes affiliate links, which means we may earn a small commission at no extra cost to you if you choose to make a purchase through these links.

What Makes A Dresser Sustainable?

As with anything in sustainability, there are various approaches that can make something “sustainable”.

Secondhand

With over 12 million tons (or 24 billion pounds) of furniture getting wasted each year in the United States alone, it’s definitely a great idea to look used when possible!

Secondhand not only helps divert furniture from the landfill, but reduces the need to extract new materials, whether that’s metal, wood, cotton, or increasingly, petroleum for synthetic fabrics and plastic.

Here’s where to look for secondhand dressers:

- Garage sales and estate sales (check EstateSales.net!)

- Facebook Marketplace

- OfferUp

- AptDeco

Responsibly Sourced Wood

Most storage furniture, like dressers, are made from wood (or engineered wood). While wood is a natural material, deforestation is a significant driver of climate change.

So, look for domestic or certified sustainably-sourced wood when purchasing wooden furniture. The largest most common certification is FSC, which stands for Forest Stewardship Council.

Even better is if you can find furniture made from reclaimed wood! This is basically upcycled wood that is being repurposed. This reclaimed wood can come from old barns, ships, factories, warehouses, or even wine barrels.

Non-Toxic Finishes

Unfortunately, many wood finishes contain harmful petroleum- and chemical-based solvents which can emit VOCs, or volatile organic compounds. While the toxicity is most severe during application and does reduce with time, the chemicals can build up in your home, so you may feel most comfortable minimizing risk of VOCs.

Why does this matter? Well, the EPA reports that indoor air can be 2-5 times more polluted than outdoor air — largely due to what we bring into our homes, from furniture to household cleaners.

Look for low-VOC finishes, water-based finishes, or natural oil finishes like linseed oil.

Where to Find Sustainably Made Dressers

I’ve done the grunt work for you and curated furniture brands with sustainable dressers, armoires, and wardrobes below!

1. Urban Natural

Highlights: Sustainably-Sourced Woods,

Price Range: $1,245 – $9,000+

For a one-stop shop for sustainable storage furniture, look no further than Urban Natural. The retailer has a stunning selection of timeless sustainable dressers (including non-toxic dressers for nurseries) made with responsibly sourced wood and several with non-toxic finishes too.

Urban Natural’s workshop partners use materials like solid oak, cherry, maple, and walnut — and many of the brands prioritize local sourcing as well.

2. Avocado

Highlights: Reclaimed or FSC-Certified Wood, GREENGUARD Gold Certified, Zero VOC Finish

Price Range: $1,939 – $3,999

Avocado’s sustainable dressers are made in Los Angeles in their own FSC-certified woodshop. Beautifully designed with a timeless mid-century modern or Scandinavian-inspired aesthetic, Avocado’s dressers are also built to last. Each dresser is made with either responsibly sourced FSC-Certified wood or reclaimed wood. Most of the company’s non-toxic bedroom furniture is also finished with a non-toxic zero-VOC finish to you can sleep easy.

3. Thuma

Highlights: Upcycled Solid Wood, GREENGUARD Gold Certified, Modular

Price Range: $1,165 – $3,495

Designed for maximum functionality and versatility, Thuma’s sustainable dressers give you endless options. Configure a couple drawers for a nightstand and add on more drawers vertically or horizontally for a full dresser that can fit any space.

The modular setup may be especially useful for families with evolving needs — you can add on more drawers if your needs grow or separate a large dresser into two smaller ones.

4. Medley

Highlights: Non-Toxic, USA Made

Price Range: $4,136

Medley’s sustainable dressers are handmade to order in California. The wide dresser pictured here comes in maple or walnut sourced domestically in the US.

The tops and sides are solid hardwood and FSC-certified, low-VOC CARB 2 compliant hardwood plywood is used in the rest of the dresser. The piece is finished with non-toxic natural beeswax.

5. MasayaCo

Highlights: FSC-Certified Reforested Wood, 1.2 Million Trees Planted

Price Range: $2,295 – $2,395

MasayaCo is committed to responsible sourcing for all of their sustainable storage furniture. Each FSC-Certified piece is made to order by skilled artisans in Nicaragua from 100% solid teak wood that comes from their own reforestation projects. Even more impressive, the company leaves 40% of these projects completely untouched to thrive on its own.

Their stunning credenzas could easily be used as dressers, too.

6. West Elm Sustainably Sourced Collection

Highlights: Non-Toxic and Responsibly-Sourced Options

Price Range: $879 – $2499

West Elm is a large retailer with options for more eco-friendly dressers. Among their selection, you can curate by filters such as GREENGUARD Gold Certified, crafted in Fair Trade Certified facilities, made from responsibly-sourced wood, and/or Contract Grade (i.e. high quality + durable).

7. Crate & Barrel FSC-Certified (Honorable Mention)

Price Range: $899 – $2,699

While Crate & Barrel does not have as many sustainability efforts as other large retailers like West Elm, the company has a vast selection of FSC-certified wood storage furniture, including dressers, chests, and full wardrobes or armoires.

You’ll find an array of woods and finishes as well, from weathered rustic natural wood to dark espresso-finished wood.

More Guides Like This:

21 Best Places to Find Sustainable Furniture

8 Gorgeous Sustainable Tables to Gather Around

Best Eco-Friendly and Non-Toxic Sofas to Relax In

The post 7 Sustainable Dressers and Armoires to Store it All Away in Style (2026) appeared first on Conscious Life & Style.

7 Sustainable Dressers and Armoires to Store it All Away in Style (2026)

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits