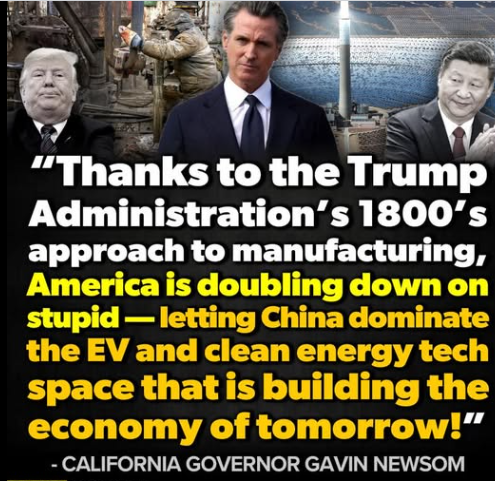

When I argue for environmental responsibility and the decarbonization of the grid, I often say:

When I argue for environmental responsibility and the decarbonization of the grid, I often say:

I know there are people who believe, perhaps because this is what they’re told by Donald Trump, that climate change is a hoax. But are there people who don’t believe in cancer? In the importance of our country’s investing in the industry that is destined the dominate the 21st Century?

Trump will be gone soon. Maybe you and I will be gone (in a different sense) before the effects of this administration’s folly in the EV and cleantech industry are fully felt.

But it’s inevitable, unless we turn this around, and soon.

Renewable Energy

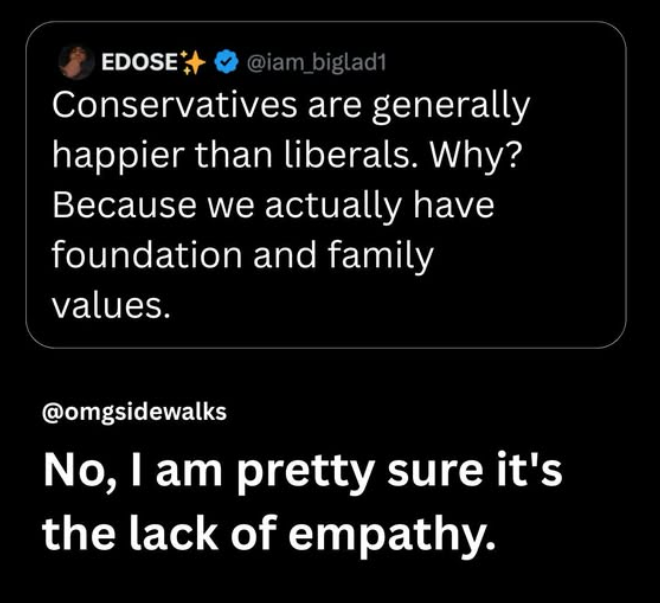

Empathy and Happiness

Exactly. Being indifferent to the suffering of others makes it easy to keep a smile on your face.

Exactly. Being indifferent to the suffering of others makes it easy to keep a smile on your face.

Renewable Energy

Nova Scotia’s Wind West Plan, Rivian Tries Wind

Weather Guard Lightning Tech

Nova Scotia’s Wind West Plan, Rivian Tries Wind

Allen covers Nova Scotia’s ambitious 60 GW Wind West offshore plan and the standoff between Ottawa and developers over who invests first. Plus a scaled-back English onshore project faces local opposition, Blue Elephant Energy triples its German wind portfolio, Adani prepares to build India’s longest onshore blade, and Rivian signs a wind PPA to power its Illinois factory.

Sign up now for Uptime Tech News, our weekly newsletter on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on YouTube, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary’s “Engineering with Rosie” YouTube channel here. Have a question we can answer on the show? Email us!

There is something happening in the wind business right now. Something big … and something small.

Let us start with big.

In Nova Scotia … Premier Tim Houston has a dream. He calls it Wind West. Sixty gigawatts of offshore wind turbines. A transmission line to move that power across Canada and into the United States. The price tag … sixty billion dollars. Forty billion for the turbines. Twenty billion for the cables.

But Ottawa says … not so fast. Federal Energy Minister Tim Hodgson told reporters the Major Projects Office needs to see private industry commit first. No private partners … no national interest designation.

And here is the catch. The developers want to see transmission infrastructure before they invest. Ottawa wants to see developers before it invests. Everybody is waiting for everybody else.

Still … Houston is not worried. He says the response from developers has been … through the roof. French firm Q Energy has already applied to pre-qualify. And Natural Resources Canada just put up nearly five million dollars for a feasibility study.

Houston says the wind is there. It blows … a lot. The only question is where the power goes.

Now … across the Atlantic.

In England … a developer is learning that sometimes bigger is not better. Calderdale Energy Park wanted to build sixty-five turbines on Walshaw Moor near Hebden Bridge in West Yorkshire. That would have made it the largest onshore wind farm in England. Last April they cut it to forty-one. Now … thirty-four. That would match the current largest site at Keadby in Lincolnshire.

Campaigners say it will still damage the peat bogs and threaten ground-nesting birds. A local parish council survey found ninety-three percent of residents opposed. The developer says it could power a quarter million homes. That application goes to the Planning Inspectorate in November.

Meanwhile … in Hamburg, Germany …

Blue Elephant Energy is doing some shopping. The company just acquired a three hundred eighty-one megawatt wind portfolio from Wind-Projekt. That is thirty-seven operating wind farms in northern Germany. Two hundred sixty megawatts already feeding the grid. Another forty-six megawatts under construction … coming online this year. And seventy-five more megawatts in the pipeline for twenty twenty-seven.

This deal will triple their German wind capacity … from one hundred seventy-three to five hundred thirty-three megawatts. It still needs approval from the German Federal Cartel Office.

Now … to India.

The Adani Group is about to build the longest onshore wind turbine blade in the country. Ninety-one-point-two meters. That is the length of a football field. Those blades will create a rotor diameter of one hundred eighty-five meters. Each rotation sweeps an area larger than three football fields combined.

The factory is at Mundra in the state of Gujarat. Current capacity … two-point-two-five gigawatts per year. They plan to double that to five … and eventually reach ten. India added six-point-three gigawatts of wind last year alone. That was an eighty-five percent jump over the year before.

And finally … back home in the American heartland.

Rivian … the electric vehicle maker … just signed a power purchase agreement with Apex Clean Energy. Fifty megawatts from the proposed Goose Creek wind farm in Piatt County, Illinois. That wind farm sits within an hour of Rivian’s flagship plant in Normal, Illinois. With this deal … Rivian could power up to seventy-five percent of its factory with carbon-free energy. An electric truck company … powered by wind.

So let us step back.

Nova Scotia dreams of sixty gigawatts off its coast. An English moor fights over thirty-four turbines. A German company triples its wind portfolio overnight. India builds blades as long as football fields. And an American truck maker turns to the prairie wind to build its future.

From the North Atlantic to the plains of Illinois … from the moors of Yorkshire to the coast of Gujarat … the wind keeps blowing. And people … keep building.

And that is the state of the wind industry for the first of March twenty twenty-six.

Join us for the Uptime Wind Energy podcast tomorrow.

Renewable Energy

Shall We Re-Write the U.S. Constitution Before the Midterms?

Insofar as the Constitution clearly assigns the states the responsibility to regulate and conduct elections, what Trump wants so desperately to do will require a significant re-write of the document that (most) Americans hold sacred.

Insofar as the Constitution clearly assigns the states the responsibility to regulate and conduct elections, what Trump wants so desperately to do will require a significant re-write of the document that (most) Americans hold sacred.

Shall We Re-Write the U.S. Constitution Before the Midterms?

-

Greenhouse Gases7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Climate Change7 months ago

Guest post: Why China is still building new coal – and when it might stop

-

Greenhouse Gases2 years ago

Greenhouse Gases2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change2 years ago

Bill Discounting Climate Change in Florida’s Energy Policy Awaits DeSantis’ Approval

-

Climate Change2 years ago

Spanish-language misinformation on renewable energy spreads online, report shows

-

Climate Change2 years ago

Climate Change2 years ago嘉宾来稿:满足中国增长的用电需求 光伏加储能“比新建煤电更实惠”

-

Climate Change Videos2 years ago

The toxic gas flares fuelling Nigeria’s climate change – BBC News

-

Carbon Footprint2 years ago

Carbon Footprint2 years agoUS SEC’s Climate Disclosure Rules Spur Renewed Interest in Carbon Credits